Abstract

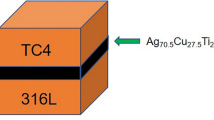

Microstructure and fracture behavior of brazed joint between commercially pure titanium and low carbon steel using silver (Ag–34Cu–2Ti) and copper (Cu–12Mn–2Ni) based alloys have been characterized to determine the effect of brazing parameters and chemical composition on the strength of brazed joints. It is found that the shear strength of brazed joints strongly depends on the lap width. Furthermore, the fracture path and the value of shear strength significantly changed with the type of filler alloy. The two filler metals showed metallurgical interaction with steel and titanium forming different kinds of intermetallic compounds such as CuTi, Cu2Ti, and FeTi with silver based filler and Ti2Cu, FeTi and TiCuFe with copper based filler.

Similar content being viewed by others

References

Block B, Haferkamp H, Ostendorf A, Meier O, Huang J, Hassel T, Bruns C (2005) In: Beyer E, Dausinger F, Ostendorf A, Otto A (eds) Proceedings of the 3rd international WLT-conference on laser in manufacturing, Munich, June 2005. AT-Fachverlag GmbH, Stuttgart, Munich, p 209

Smith LS, Threadgill P, Gittos M (1999) Welding titanium – a designer and user handbook. TWI, Abington, UK, p 1999

Wang RR, Welsch GE (1995) J Prosthet Dent 74:521

Lancaster FJ (1999) Metallurgy of welding. Abington Publishing, Cambridge, UK, p 25

Fujii H, Takahashi K, Yamashita Y (2003) Nippon Steel Technical Report No. 88(7):70

Kundu S, Ghosh M, Chatterjee S (2006) Mater Sci Eng A 428:18

Nishio K, Kato M, Yamaguchi T, Tokunaga T, Matsumoto A (2004) Welding Int 10:771

Smorygo O, Kim JS, Kim MD, Eom TG (2007) Mater Lett 1:305

He P, Feng JC, Zhou H (2005) Mater Charact 54:338

Liu CC, Ou CL, Shiue RK (2002) J Mater Sci 11:2225

Olson DL, Siewert TA, Liu S, Edwards GR (1993) ASM handbook: welding, brazing and soldering. ASM International, Materials Park, Ohio, p 271

Humpston G, Jacobson DM (1993) Principles of soldering and brazing. ASM International, Materials Park, Ohio, p 19

Shiue RK, Wu SK, Chen SY (2003) Acta Mater 51:1991

He P, Feng JC, Xu W (2006) Mater Sci Eng A 418:53

van Beek JA, Kodentsov AA, van Loo FJJ (1995) J Alloys Compd 217:97

Hong IT, Koo CH (2005) Mater Chem Phys 94:131

Flom Y, Wang L (2004) Welding J 7:32

Lugscheider E, Reimann H, Knotek O (1977) Welding J 6:189

Vander Voort GF (2004) Metals handbook, metallography and microstructures. ASM International, Materials Park, Ohio, p 899

Kundu S, Ghosh M, Laik A, Bhanumurthy K, Kale GB, Chatterjee S (2005) Mater Sci Eng A 407:154

Acknowledgments

The authors gratefully acknowledge the financial support from Alexander von Humboldt Foundation (AVH), Federal Republic of Germany.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elrefaey, A.AM., Tillmann, W. Microstructure and mechanical properties of brazed titanium/steel joints. J Mater Sci 42, 9553–9558 (2007). https://doi.org/10.1007/s10853-007-1935-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1935-9