Abstract

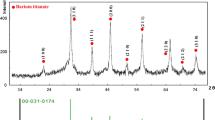

A solid-state reaction method was used to synthesize nano-sized, Ca-doped BaTiO3 powder with high tetragonality (=c/a) in order to increase the volumetric efficiency of multilayer ceramic capacitors (MLCCs). The reaction temperatures for three different starting material combinations were examined by thermogravimetric/differential thermal analysis (TG/DTA). Nano-sized starting materials and the mechanochemical activation of the needle-shaped BaCO3 via high-energy milling were effective in decreasing the reaction temperature. In addition, the results showed that the tetragonality of fine Ca-doped BaTiO3 could be enhanced by 2-step heat treatment, consisting of holding at 800 °C for 1 h followed by consecutive heating to the target temperature, without any significant grain growth than that of the conventional 1-step calcination. The synthesized particles heat-treated at 950 and 1,000 °C by 2-step heat treatment were confirmed by characterization to have an average size of 128 and 212 nm, and a tetragonality of 1.0097 and 1.0105, respectively, which are higher tetragonality values than those previously reported for similar sized particles.

Similar content being viewed by others

References

Yoon DH, Lee BI (2002) J Ceram Proc Res 3:41

Merz WJ (1949) Phys Rev 76:1221

Kwon SW, Yoon DH (2006) Ceram Int (in press)

Sakabe Y, Wada N, Hiramatsu T, Tonogaki T (2002) Jpn J Appl Phys 41:6922

Wada S, Yasuno H, Hoshina T, Nam SM, Kakemoto H, Tsurumi T (2003) Jpn J Appl Phys 42:6188

Kishi H, Mizuno Y, Chazono H (2003) Jpn J Appl Phys 42:1

Sakabe Y (2000) In: Jean JH, Gupta TK, Nair KM, Niwa K (eds) Ceramic transactions, vol 97. American Ceramic Society, OH, p 1

Sakabe Y, Wada N, Hamaji Y (1998) J Korean Phys Soc 32:S260

Uchino K, Sadanaga E, Hirose T (1989) J Am Ceram Soc 72:1555

Begg BD, Rvance E, Nowotny J (1994) J Am Ceram Soc 77:3186

Vivekanandan R, Kutty TRN (1989) Powder Tech 57:181

Arlt G, Hennings D, With GD (1985) J Appl Phys 58:1619

Hennings DFK, Schreinemacher BS, Schreinemacher H (2001) J Am Ceram Soc 84:2777

Kong LB, Ma J, Huang H, Zhan RFG, Que WX (2002) J Alloys Compos 337:226

Brzozowski E, Castro MS (2003) Thermochim Acta 398:123

Gomez-Yanez C, Benitez C, Balmori-Ramirez H (2000) Ceram Int 26:271

Buscaglia MT, Bassoli M, Buscaglia V (2005) J Am Ceram Soc 88:2374

Berbenni V, Marini A, Bruni G (2001) Thermochim Acta 374:151

Ando C, Yanagawa R, Chazono H, Kishi H, Senna M (2004) J Mater Res 19:3592

Brzozowski E, Castro MS (2000) J Eur Ceram Soc 20:2347

Kwon SW, Yoon DH (2006) J Eur Ceram Soc 27:247

Lotnyk A, Senz S, Hesse D (2006) Solid State Ionics 177:429

Beauger A, Mutin JC, Niepce JC (1983) J Mater Sci 18:3543, DOI: 10.1007/BF00540726

O’neil MJ, Smith A, Heckelman PE, Obenchain JR, Gallipeau JAR, D’arecca MA, Budavari S (2001) In The Merck Index. MERCK & CO, Inc, NJ, p 9549

Levin EM, Mcmurdie HF (1975) In: Reser MK (ed) Phase diagrams for ceramists. American Ceramic Society, Westerville, OH, p 4258

Felgner KH, Muller T, Langhammer HY, Abicht HP (2004) Mater Lett 58:1943

Shaikh AS, Vest GM (1986) J Am Ceram Soc 69:682

Maison W, Kleeberg R, Heimann RB, Phanichphant S (2003) J Eur Ceram Soc 23:127

Chen KY, Chen YW (2004) Powder Tech 41:69

Tsurumi T, Sekine T, Kakemoto H, Hoshina T, Nam SM, Yasuno H, Wada S (2006) J Am Ceram Soc 89(4s):1337

Acknowledgements

This work was supported by Pohang National Center for Nanomaterials Technology. The authors would like to thank Dr. K. H. Hur, Mr. H. S. Jung and Mr. D. S. Lee at Samsung Electro-Mechanics Co. for their considerable cooperation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ryu, SS., Yoon, DH. Solid-state synthesis of nano-sized BaTiO3 powder with high tetragonality. J Mater Sci 42, 7093–7099 (2007). https://doi.org/10.1007/s10853-007-1537-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1537-6