Abstract

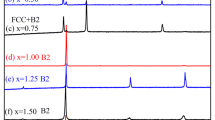

The crystallization behaviour and the mechanical properties of rapidly solidified Al87.5Ni7Mm5Fe0.5 alloy ribbons have been examined in both as-melt-spun and heat-treated condition using differential scanning calorimetry, X-ray diffractometry (XRD), transmission electron microscopy (TEM), tensile testing and Vicker’s microhardness machine. XRD and TEM studies revealed that the as-melt-spun ribbons are fully amorphous. The amorphous ribbon undergoes three-stage crystallization process upon heating. Primary crystallization resulted in the formation of fine nanocrystalline fcc-Al particles embedded in the amorphous matrix. The second and third crystallization stages correspond to the precipitation of Al11(La,Ce)3 and Al3Ni phases, respectively. Microhardness and tensile strength of the ribbons were examined with the variation of temperature and subsequently correlated with the evolved structure. Initially, the microhardness of the ribbon increases with temperature followed by a sharp drop in hardness owing to the decomposition of amorphous matrix that leads to formation of intermetallic compounds

Similar content being viewed by others

References

Inoue A, Horio Y, Kim YH, Masumota T (1992) Mater Trans JIM 33:669

Chen H, He Y, Shiflet GJ (1991) Scripta Metall 25:1421

Inoue A (1998) Prog Mater Sci 43:365

Kim YH, Inoue A, Masumota T (1991) Mater Trans JIM 32:331

Sahoo KL, Wollgarten M, Kim KB, Banhart J (2005) J Mater Res 44:1075

Inoue A, Ohtera K, Tsai AP (1988) Jpn J Appl Phys 27:L479

Sahoo KL, Wollgarten M, Haug J, Banhart J (2005) Acta Mater 53:3861

Kim YH, Hiraga K, Inoue A, Masumota T, Jo HH (1994) Mater Trans JIM 35:293

Kim YH, Inoue A, Masumota T (1990) Mater Trans JIM 32:747

Ping DH, Hono K, Inoue A (2000) Metall Mater Trans 31A:607

Zhong ZC, Jiang XY, Greer AL (1997) Mater Sci Eng A 226–228:531

Kim HS, Warren PJ, Cantor B, Lee HR (1999) Nano Struc Mater 11:241

Kim TS, Hong SJ, Lee BT (2003) Mater Sci Eng A 363:81

Hong SJ, Kim HS, Suryanarayana C, Chun BS (2003) Mater Sci Tech.19:966

Inoue A (1998) Prog Mater Sci 43:365

Wang SH, Bian XF, Wang HR (2003) Mater Lett 58:539

Chang TH, Botten RR (1997) Mater Sci Eng A 226–228:183

He Y, Poon SJ, Shiflet GJ (1988) Science 241:1640

Allen DR, Foley JC, Perepezko JH (1998) Acta Met 46:431

Chen LC, Spaepen F (1991) J Appl Phys 69:679

Hawksworth A, Rainforth WM, Jones H (1999) Mater Sci Eng A 262:159

Joint committee on powder diffraction standards, files No. 24–501 and 48–1841

Chen LC, Spaepen F (1988) Nature 336:336

Johnson WA, Mahl RF (1939) Trans Am Inst Min Metal Eng 135:416

Avrami M (1941) J Chem Phys 9:177

Christian J (1975) The theory of transformation in metals and alloys, Part 1, Equilibrium and general kinetic theory. Pergamon press, Oxford

Munoz-Morris MA, Surinach S, Varga LK, Baro MD, Morris DG (2002) Scripta Mater 47:31

Kim TS, Hong SJ, Lee BT (2003) Mater Sci Eng A 363:81

Acknowledgement

The authors thank Dr. N. Wanderka, Scientist, Hahn–Meitner–Institute Berlin for her help in performing HRTEM measurements and Director, National Metallurgical Laboratory for his permission to publish the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahoo, K.L., Poddar, P., Das, G. et al. Crystallization behaviour and mechanical properties of rapidly solidified Al87.5Ni7Mm5Fe0.5 amorphous alloy. J Mater Sci 42, 6665–6671 (2007). https://doi.org/10.1007/s10853-007-1530-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1530-0