Abstract

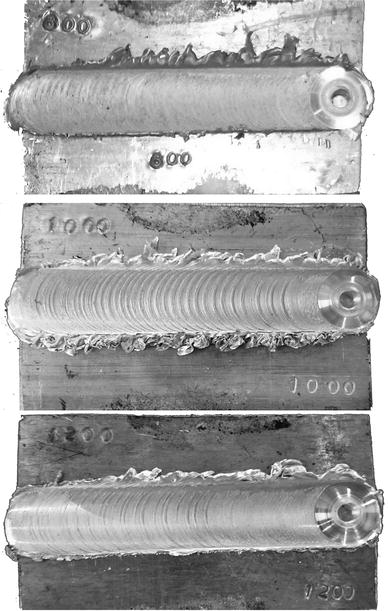

Taguchi methodology has been applied to the production process of aluminium foams to investigate the variability detected in several properties (including bulk density, outward appearance and density homogeneity along foaming direction), for foaming tests carried out under identical conditions. The analysis of the process has been performed separately for two different alloys, the 4045 and 6061. The results have allowed finding the main factors that influence those properties. In addition, it has been possible to establish those foaming conditions able to minimize the variability in density, to improve the outward appearance and to obtain a higher homogeneity in density, all at the same time. Different final factors have been found for the two alloys; such differences have been explained in terms of the different viscosity of the aluminium melts as well as the different content of foaming agent.

Similar content being viewed by others

References

Banhart J (2001) Prog Mater Sci 46:559

Baumgärtner D, Banhart J (2000) Adv Eng Mater 2(4):168

Banhart J (1999) Europhys News 1/1999

Simancík F, Kovácik J, Schörghuber F (1997) In: Banhart J (ed) Metallschäume, proc symp metal foams. MIT-Verlag/Publishing Bremen, Bremen, Germany, p 171

Schäffler P, Rajner W (2003) International conference “advanced metallic materials.” Smolenice, Slovakia, p 258

Maurer M, Zhao L, Lugscheider E (2002) Adv Eng Mater 4(10):791

Gergely V, Clyne B (2000) Adv Eng Mater 2(4):175

Duarte I, Banhart J (2000) Acta Mater 48:2349

Helfen L, Baumbach T, Stanzick H, Banhart J, Elmoutaouakkil A, Cloetens P (2002) Adv Eng Mater 4(10):808

Stanzick H, Klenke J, Danilkin S, Banhart J (2002) Appl Phys A 74(Suppl):S1118

Banhart J, Bellmann D, Clemens H (2001) Acta Mater 49:3409

Gergely V, Clyne TW (2004) Acta Mater 52:3047

Koehler SA, Stone HA, Brenner MP, Eggers J (1998) Phys Rev E 58(2):2097

Wübben T, Stanzick H, Banhart J, Odenbach S (2003) J Phys: Condens Mater 15:S427

Yang CC, Nakae H (2003) J Mater Process Technol 141:202

Zhaojin WU, Deping HE (2000) Chin Sci Bull 45(18):1667

Yang CC, Nakae H (2000) J Alloys Compd 313:188

Rodríguez-Pérez MA, Almanza O, del Valle JL, González A, de Saja JA (2001) Polym Testing 20(3):253

Pan LK, Wang CC, Hsiao YC, Ho KC (2004) Optics Laser Technol 37:33

Taner T, Antony J (2006) Int J Health Care Qual Assur Inc. Leadersh Health Serv, vol 19, p XXVI

Roy T (1990) A premier on the Taguchi method. Society of Manufacturing Engineers, Michigan

Bendell J, Disney WA (1989) Pridmore Taguchi methods: applications in world industry. IFS Publications, UK

Ross PJ (1988) Taguchi techniques for quality engineering. Lost function, Orthogonal experiment, parameters and tolerance design. Mc Graw-Hill

Disndale AT, Quested PN (2004) J Mater Sci 39:7221. DOI: 10.1023/B:JMSC.0000048735.50256.96

Acknowledgements

Financial support from the Spanish Ministry of Science and Education (MAT 2003-06797, MAT 2002-04505-C02-01, FPU grants) is gratefully acknowledged. FEDER funding is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Solórzano, E., Reglero, J.A., Rodríguez-Pérez, M.Á. et al. Improvement of the foaming process for 4045 and 6061 aluminium foams by using the Taguchi methodology. J Mater Sci 42, 7227–7238 (2007). https://doi.org/10.1007/s10853-007-1529-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1529-6