Abstract

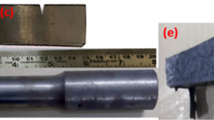

In this study, improvement of fracture toughness and strength of gray cast iron by reinforcing steel fiber was investigated. Three point bend specimens were used to calculate the flexural strength and fracture toughness. Fracture toughness of the reinforced cast iron with two distinct volume fraction (Vf = 0.05 and 0.08) were calculated by compliance method and J-integral method using single specimen technique. The study shows that fiber reinforced composite has higher fracture toughness and flexural strength than cast iron without reinforcement. Also, fracture toughness increases with increasing volume fraction of reinforcement. Optical and scanning electron microcopy (SEM) analyses were used to examine the microstructure and fracture surface. It is noted that the carbon diffuses from gray cast iron to steel fiber and graphite free transition regions with high hardness were observed due to the carbon diffusion.

Similar content being viewed by others

References

Antolovich SD, Shete PM, Chanani GR (1972) ASTM STP514. American Society for Testing and Materials. p 114

Antolovich SD, Kasi K, Chanani GR (1972) ASTM STP514. American Society for Testing and Materials, p 135

Akdemir A, Arıkan H, Kuş R (2005) Mater Sci Technol 21:1099

Soboyejo WO, Ye F, Chen LC, Bahtishi N, Schwartz DS, Lederich RJ (1996) Acta Mater 44:2027

Chiang CR (2000) J Mater Sci 35:3161, doi: 10.1023/A:1004884322817

Qin S, Zhang G (2002) J Mater Sci 37:879, doi: 10.1023/A:1013868620945

Arpon R, Narciso J, Louis E, Cordovilla CG (2003) Mater Sci Technol 19:1225

Futato RJ, Aadland JD, van der Sluy WA, Lowe AL (1985) ASTM STP856. American Society for Testing and Materials, p 84

Prokopski G, Langier B (2000) Cement Concrete Res 30:1427

Panontin TL, Makino A, Williams JF (2000) Eng Fract Mech 67:293

Begley JA, Landes JD (1972) ASTM STP 514. American Society for Testing and Materials, p 1

Rice JR, Paris PC, Merkle JG (1973) ASTM STP 536. American Society for Testing and Materials, p 231

Hickerson J (1976) ASTM Committee Meeting E-24, Lake Buena Vista Fla

Gudas JP, Davis DA (1982) J Test Eval 10:252

Schwalbe KH, Hellman D, Heerens J, Knaack J, Roos JM (1985) ASTM STP856. American Society for Testing and Materials, p 338

Balton JD, Gant AJ (1998) J Mater Sci 33:939, doi: 10.1023/A:1004303609990

Neal BK, Priest RH (1985) ASTM STP 856. American Society for Testing and Materials, p 375

Gerberich WW (1971) J Mech Phys of Solids 19:71

Arikan H, Avci A, Akdemir A (2004) Polymer Test 23:615

Rohatgi A, Harach DJ, Vecchio KS, Harvey KP (2003) Acta Materialia 51:2933–2957

Şimşir M, Öztürk T, Doruk M (2004) Turkish J Eng Env Sci 28:397

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Şimşir, M. Fracture behavior and microstructure of steel fiber reinforced cast iron. J Mater Sci 42, 6701–6707 (2007). https://doi.org/10.1007/s10853-006-1493-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1493-6