Abstract

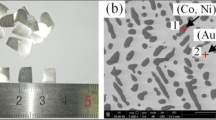

Based on the structure characteristic of Ti3AlC2 and the easy formation of Ti3Al1 − x Si x C2 solid solution, a Si interlayer was selected to join Ti3AlC2 layered ceramic by diffusion bonding method. Joining was performed at 1,300–1,400 °C for 120 min under 5 MPa load in an Ar atmosphere. The phase composition and interface microstructure of the joints were investigated by XRD, SEM and EPMA. The results revealed that Ti3Al(Si)C2 solid solution formed at the interface. The mechanism of bonding is attributed to silicon diffusing inward the Ti3AlC2. The strength of joints was evaluated by a 3-point bending test. The jointed specimens exhibit a high flexural strength of 285 ± 11 MPa, which is about 80% of that of the Ti3AlC2; and retain this strength up to 1,000 °C. The high mechanical performance of the joints indicates that diffusion bonding via a Si interlayer is effective to bond Ti3AlC2 ceramic.

Similar content being viewed by others

References

Barsoum MW (2000) Prog Solid Chem 28:201

Wang XH, Zhou YC (2002) Acta Mater 50:3141

Tzenov NV, Barsoum MW (2000) J Am Ceram Soc 83:825

Lopacinski M, Puszynski J, Lis J (2001) J Am Ceram Soc 84:3051

Zhou YC, Wang XH (2001) J Mater Chem 11:2335

Bao YW, Chen JX, Wang XH, Zhou YC (2004) J Eur Ceram Soc 24:855

Bao YW, Wang XH, Zhang HB, Zhou YC (2005) J Eur Ceram Soc 25:3367

Wang XH, Zhou YC (2003) Corros Sci 45:891

Wang XH, Zhou YC (2003) Chem Mater 15:3716

Loehman RE, Tomsia AP (1988) Am Ceram Soc Bull 67:375

Sun ZM, Ahuja R, Scheider JM (2003) Phys Rev B 68:224112

Meng FL, Zhou YC, Wang JY (2005) Scripta Mater 53:1369

Ganguly A, Zhen T, Barsoum MW (2004) J Alloys Compd 376:287

Barsoum MW, Ali M, El-Raghy T (2000) Metall Mater Trans 31A:1857

Wang JY, Zhou YC (2003) J Phys: Condens Matter 15:5959

Zhou YC, Zhang HB, Liu MY, Wang JY, Bao YW (2004) Mater Res Innov 8:97

Zhou YC, Chen JC, Wang JY (2006) Acta Mater 54:1317

Li M, Liu G, Zhang Y, Zhou Y (2003) Oxid Metal 60:179

Wang XH, Zhou YC (2002) J Mater Chem 12:455

Pietzka MA, Schuster JC (1994) J Phase Equilib 15:392

Gulbrasen EA, Endrew KF, Brassar FA (1966) J Electrochem Soc 113:834

Chen JX (2005) Methods of strengthening layered machinable ternary ceramic Ti3AlC2. PhD thesis, Inst. Met. Res., CAS, p 102

Acknowledgements

This work was supported by the National Science Foundation of China under Grant Nos. 50371095, 50232040, 50302011, 90403027; and cooperation project of Chinese Academy of Sciences and French Atomic Energy Commission.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, X.H., Li, M.S., Li, T.P. et al. Diffusion bonding of Ti3AlC2 ceramic via a Si interlayer. J Mater Sci 42, 7081–7085 (2007). https://doi.org/10.1007/s10853-006-1491-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1491-8