Abstract

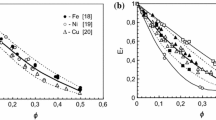

The elastic moduli of powdered materials undergoing uniaxial compaction was investigated, paying particular attention to effects of solid phase material properties and initial particle shape. Elastic properties were characterised by the isotropic elastic moduli Poisson’s ratio and Young’s modulus, calculated from elastic wave speeds measured in the axial (pressing direction). To isolate material property effects, three different ductile metal powders (copper, stainless steel, and aluminium) with equivalent particle shape (spheroidal) were tested. Comparison with similar measurements for a brittle spheroidal powder (glass) illustrated that solid phase yield mechanism affects the evolution of pore character, and hence bulk elastic properties of the powder compact. Pore character was also studied separately by comparing copper powders with differing particle shapes (spheroidal, irregular, and dendritic).

For all powders, Young’s modulus increased monotonically with compaction (reducing porosity). For the ductile spheroidal powders, differences in evolution of Young’s modulus with compaction were accounted for by solid phase elastic properties. The different morphology copper powders showed an increase in compact compliance as particle (pore) ruggedness increased. Poisson’s ratio followed a concave porosity dependence: decreasing in the initial stages of compaction, then increasing as porosity approached zero. Comparison between powders indicated the initial decrease in Poisson’s ratio was insensitive to solid phase material properties. However, as the compact approached solid phase density, the Poisson’s ratio—porosity locus diverged towards corresponding solid phase values for each particle material, indicating an influence of solid phase elastic properties.

Similar content being viewed by others

References

Leheup ER, Moon JR (1980) Powder Metal 23:15

Straffelini G, Fontanari V, Molinari A (1999) Mater Sci Eng A 260:197

Moon JR (1989) Powder Metall 32:132

Sawicki A, Swidzinski W (1998) Powder Technol 96:24

Hardin BO, Blandford GE (1989) J, Geotech Engng 115:788

Jones MP, Blessing GV (1988) In: McGonnagle WJ (ed) International advances in nondestructive testing, vol 13. Gordon and Breach, New York, p 175

Kathrina T, Rawlings RD (1997) J Eur Ceram Soc 17:1157

ALeR Dawson L. Piché, Hamel A (1996) Powder Metall 39:275

Jones MP, Blessing GV (1987) In: Proceedings of 1987 IEEE ultrasonics symposium. 1186:587

Kendall K (1990) Br Ceram Trans 89:211

Brettell JM (1989) J Aust Phys 42:627

Brettell JM (1994) J Acoust Soc Am 95:2281

Jones MP, Blessing GV (1986) Nondestructive Testing Commun 2:155

Kathrina T, Rawlings RD (1996) Br Ceram Trans 95:233

ALeR Dawson, Pelletier S, Bussiére J (1996) Adv Powder Metall Particulate Mater 2:303

Rice W (1998) Porosity of ceramics. Marcel Dekker New York

Carnavas PC, Page NW (1998) J Mater Sci 33:4647

Luo J, Stevens R (1999) Ceram Int 25:281

Dean EA (1983) J Am Ceram Soc 66:847

Martin LP, Dadon D, Rosen M (1996) J Am Ceram Soc 79:1281

Green DJ, Nader C, Brezny R (1990) In: Handwerker CA, Blendell JE, Keyser W (eds) Ceramic transactions, vol. 7, Sintering of advanced ceramics. American Ceramic Society, Ohio

Nagarajan A (1971) J Appl Phys 42:3693

Chang L-S, Chuang T-H, Wei WJ (2000) Mater Charact 45:221

Asmani M, Kermel C, Leriche A, Ourak M (2001) J Eur Ceram Soc 21:1081

Adachi T, Sakka S (1990) J Mater Sci 25:4732

Cytermann R, Guyon E, Roux S (1988) Powder Metall Int 20:23

Ashkin D, Haber RA, Wachtman JB (1990) J Am Ceram Soc 73:3376

Haynes R, Egediege JT (1989) Powder Metall 32:47

Soga N, Schreiber E (1968) J Am Ceram Soc 51:465

Zimmerman RW (1985) J Appl Mech 52:606

Zimmerman RW (1986) J Appl Mech 53:500

Tsukrov I, Novak J (2002) Int J Solids Struct 39:1539

Rice RW (1976) J Am Ceram Soc 59:536

Rice RW (1997) J Mater Sci 32:1801

Boccaccini AR, Ondracek G, Mazilu P, Windelberg D (1993) J Mech Behav Mater 4:119

Boccaccini AR (1994) J Am Ceram, Soc 77:2779

Nanjangud SC, Brezny R, Green DJ (1995) J Am Ceram Soc 78:266

Patterson BR, Miljus KL, Knopp WV (1984) Powder Metal Report 39:145

Yeheskel O, Pinkas M, Dariel MP (2003) Mater Lett 57:4418

Hentschel ML, Page NW (2003) Part Part Syst Charact 20:25

Mason WP (1958) Physical acoustics and the properties of solids. Van Nostrand, New Jersey

Hentschel ML, Page NW, Elastic properties of powders during compaction. Part 2: Elastic anisotropy. Accepted for publication in J. Mater. Sci

Hentschel ML (2002) PhD Thesis, The University of Newcastle

Kalpakjian S (1985) Manufacturing processes for engineering materials. John Wiley and Sons, Chichester

Bever B (1986) Encyclopaedia of materials science and engineering. Plenum Press, New York

Drumheller DS (1998) Introduction to wave propagation in nonlinear fluids and solids. Cambridge University Press, Cambridge

Abdel -Ghani M, Petrie JG, Seville JPK, Clift R, Adams MJ (1991) Powder Technol 65:113

Acknowledgement

The authors gratefully acknowledge scholarship support for MLH through the Australian Research Council Small Grants Scheme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hentschel, M.L., Page, N.W. Elastic properties of powders during compaction. Part 1: Pseudo-isotropic moduli. J Mater Sci 42, 1261–1268 (2007). https://doi.org/10.1007/s10853-006-1145-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1145-x