Abstract

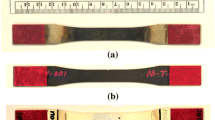

Two commercial grade silicon nitride ceramics (Honeywell GS44 and Kyocera SN235) were exposed to an oil ash to evaluate the long-term corrosion/oxidation resistance in a simulated diesel engine environment. The exposure condition was at 850 °C for 1000 h in air. Subsequently, the exposed specimens were tested in flexure for strength degradation at room temperature and 850 °C at stressing rates of 30 MPa/s and 0.003 MPa/s in air, respectively. A similar set of specimens not exposed to the oil ash was also tested in flexure for purpose of comparison. Little change in strength was measured after 1000 h exposure in the oil ash environment. Also, the values of Weibull modulus obtained for all of the exposed silicon nitride materials were similar to those with the unexposed specimens whose strength were obtained under the same conditions. However, both exposed and unexposed GS44 specimens exhibited a low fatigue exponent, suggesting a susceptibility to slow crack growth at test temperature. In addition, detailed SEM/EDAX analyses indicated that no oil ash elements (e.g., Zn, Ca, P, Na, and S) were detected beneath a thin layer in the surface; thus, there were no changes in the chemistry of the secondary phase(s) within the bulk. These elements were detected only in a region about 1–3 μm below the exposed surface, but no apparent changes in microstructure observed. Results of mechanical properties and microstructural characterizations indicated that these candidate silicon nitride materials exhibited excellent corrosion/oxidation resistance in the simulated diesel engine environment and, based on their excellent mechanical strengths, would be ideal candidates for diesel engine exhaust valve applications.

Similar content being viewed by others

References

Richerson DW (1982) Modern ceramic engineering. Marcel Dekker, Inc., New York, NY

Wills RR (1988) Commun Am Ceram Soc 72:1261–1264

Rodgers G, Southam R, Reinicke-Murmann J, Kreuter P (1990) Analysis of potential improvements in engine behavior due to ceramic valve train components. Society of Automotive Engineers, Paper No. 900452

Hamminger R, Heinrich J (1993) Development of advanced silicon nitride valves for combustion engines and some practical experience on the road. Proceedings of the Materials Research Society Symposia, Vol. 287: 513–518

Wereszczak AA, Lin H-T, Kirkland TP, Andrews MJ, Lee SK (2002) J Mater Sci 37:2669–2684

Abi-Akar HM (2000) A test method to evaluate high temperature corrosion. Paper No. 00530, Corrosion 2000, NACE International Annual Meeting, Houston, TX

Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperatures (1999) ASTM C1161, Annual Book of ASTM Standards, Vol. 15.01, American Society for Testing and Materials, West Conshohocken, PA

Life Prediction Methodology for Ceramic Components of Advanced Heat Engines, Phase 1 (1995) Prepared by AlliedSignal Engines, Phoenix, AZ, ORNL/Sub/89-SC674/1–2, DOE Office of Transportation Technologies

Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics (1999) ASTM C1239, Annual Book of ASTM Standards, Vol. 15.01, American Society for Testing and Materials, West Conshohocken, PA

Acknowledgements

The authors thank Drs. M. J. Lance, T. N. Tiegs, and P. F. Becher for reviewing the manuscripts and helpful discussions. Research sponsored by the U.S. DOE, Office of Transportation Technologies, Heavy Vehicle Propulsion Materials Program, under Contract DE-AC05-00OR22725 with UT-Battelle, LLC.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, H.T., Kirkland, T.P., Wereszczak, A.A. et al. Strength retention of silicon nitride after long-term oil immersion exposure. J Mater Sci 41, 8313–8319 (2006). https://doi.org/10.1007/s10853-006-1015-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1015-6