Abstract

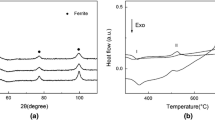

The effect of intercritical heat treatments on the tensile properties of iron-based P/M steels was investigated. For this purpose, atomized iron powder (Ancorsteel 1000) was admixed with 0.3 wt.% graphite powder. Tensile test specimens were cold pressed at 700 MPa and sintered at 1120 °C for 30 min under pure argon gas atmosphere. After sintering, ∼20% pearlite volume fraction in a ferrite matrix was obtained. To produce coarse ferrite + martensite microstructures, the sintered specimens were intercritically annealed at 724 and 760 °C and quenched in water. To obtain fine ferrite + martensite microstructures, the sintered specimens were first austenitized at 890 °C and water-quenched to produce a fully martensitic structure. These specimens were then intercritically annealed at 724 and 760 °C and re-quenched. After the intercritical annealing at 724 and 760 °C and quenching, martensite volume fractions were ∼ 18% and 43%, respectively, in both the coarse- and fine-grained specimens. Although the intercritically annealed specimens exhibited higher yield and tensile strength than the as-sintered specimens, their elongation values were lower. Specimens with a fine ferrite + martensite microstructure showed high yield and tensile strength and ductility in comparison to specimens with a coarse ferrite + martensite microstructure. The strength values of specimens increased with increasing martensite volume fraction.

Similar content being viewed by others

References

German RM (1998) Powder metallurgy of iron and steel. Willey, USA, pp 34

Danninger H, Spoljaric D, Weiss B (1997) Int J Powder Metall 33:43

Straffelini G, Fontanari V, Molinari A (1999) Mater Sci Eng A 260:197

Sun S, Pugh M (2000) Mater Sci Eng A 276:167

Tavares SSM, Pedroza PD, Teodósio JR, Gurova T (1999) Scr Mater 40(8):887

Lis J, Morgiel J, Lis A (2003) Mater Chem Phys 81:466

Sarwar M, Priestner R (1996) J Mater Sci 31:2091

Kim NJ, Nakagawa AH (1986) Mater Sci Eng 83:145

Cai X-L, Garratt-Reed AJ, Owen WS (1985) Metall Trans A 16:543

Aksoy M, Karamış MB, Evin E (1996) Wear 19(2):428

Ahn YS, Kim HD, Byun TS, Oh YJ, Kim GM, Hong JH (1999) Nucl Eng Des 194(2–3):161

Bayram A, Uğuz A, Ula M (1999) Mater Characterization 43(4):259

Kim KJ, Lee CG, Lee S (1997) Scr Mater 38(1):27–32

Lis J, Lis AK, Kolan C (2005) J Mater Process Technol 162–163:350

Speich GR, Demarest VA, Miller RL (1981) Metall Trans A 12:1419

Garcia CI, Deardo AJ (1980) Metall Trans A 12A:521

Kim KJ, Lee CG, Lee S (1997) Scr Mater 38(1):27

El-Sesy IA, El-Baradie ZM (2003) Mater Lett 25:580

Tekeli S, Güral A (2005) Mater Sci Eng A 406:172

D’Armas H, Llanes L, Peñafiel J, Bas J, Anglada M (2000) Mater Sci Eng A 277:291

Mondal DK, Dey RM (1992) Metall Trans A 149A:173

Speich GR (1981) Physical metallurgy of dual-phase steel. Metall Soc of AIME, pp 3–45

Chawla N, Murphy TF, Narasimhan KS, Koopman M, Chawla KK (2001) Mater Sci Eng A 308:180

Jeong WC, Kim CH (1988) Metall Trans A 19(2):309

Ahmad E, Manzoor T, Ali KL, Akhter JI (2000) J Mater Eng Perform 9(3):306

Eldis GT (1979) In: Kot RA, Morris JW (eds) Structure and properties of dual phase steels. AIME, New York, pp 202–220

Speich RG, Miller RL (1979) In: Kot RA, Morris JW (eds) Structure and properties of dual-phase steels. AIME, New York, pp 145–182

Davies RG (1979) In: Davenport AT (ed) Formable HSLA and dual-phase steels. Warrendale PA, AIME, pp 25–40

Straffelini G, Molinari A (2002) Mater Sci Eng A 334:96

Spitzig WA, Smelser RE, Richmond O (1988) Acta Metall 36(5):1201

Exner HE, Pohl D (1978) Powder Metall Int 10(4):193

Dudrova E, Kabatova M (2004) Proc. Vienna PM Word Conf (EPMA) 3:193–198

Chawla N, Deng X (2005) Mater Sci Eng A 390:98

Chawla N, Polasik S, Narasimhan KS, Koopman M, Chawla KK (2001) Int J Powder Metall 37:49

Danninger H, Spoljaric D, Weiss B (1997) Int J Powder Metall 33:43

Chen HC, Cheng GH (1989) J Mater Sci 24:1991

Sidjanin L, Miyasato S (1989) Mater Sci Technol 5(12):1200

Acknowledgements

The authors are grateful to the DPT (the State Planning Organization of Turkey) for the financial support given under project number 2002K120250 and to Northeastern University, USA, for the use of laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Güral, A., Tekeli, S. & Ando, T. Tensile properties of iron-based P/M steels with ferrite + martensite microstructure. J Mater Sci 41, 7894–7901 (2006). https://doi.org/10.1007/s10853-006-0871-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0871-4