Abstract

The chemistry of molten alloy plays an important role on grain refining. Small addition of alloying elements reduces the grain size of the as-solidified structures to some degree depending on the alloy efficiency. The effect of dissolved Ti has been studied on the microstructure of Al–Si foundry alloys cast conventionally and by semi-solid casting routes. It is shown that Ti in solution could restrict the grains and globules size in both processes. A parallel plate compression test machine was employed to study the effect of dissolved Ti on the rheological behavior of the billets. It was confirmed billets with higher dissolved Ti-content have superior flow.

Similar content being viewed by others

Notes

\( {\hbox{Sphericity }} = {\hbox{ }}\frac{{4\pi A}} {{P^2 }} \)where A is total area of primary particles and P is perimeter of liquid–solid interface. The closer the sphericity to one, the higher is the globularity of the particle.

\( S_{\hbox{v}} = \frac{4} {\pi }\frac{P} {A} \)

Commercial software for calculation of equilibria, thermodynamic properties and phase diagrams http://www.thermocalc.com

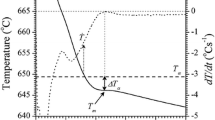

The temperature at which mass flow of the molten alloy changes to interdendritic flow.

References

Kissling RJ, Wallace JF (1963) Foundry(June) 78

Chalmers B (1964) Principles of solidification. John Wiley & Sons Inc, New York

Quested TE, Dinsdale AT, Greer AL (2005). Acta Mater 53:1323

Maxwell I, Hellawell A (1975) ACTA Metal 23:229–237

Johnsson M, Backerud L (1996) Metallkde Z 87:216–220

McCartney DG (1989). Int Mater Rev 34(5):247–260

Backerud L, Johnsson M (1996) TMS Light Metals 679

Easton MA, StJohn DH (2001) Acta Mater 49:1867–1878

Wan G, Witulski T, Hirt G (1993) In: Thixoforming of Al alloys using modified chemical grain refinement for billet production – Conference on aluminum alloys: New Process Technologies, Italy, June 1993. pp 129–141

Gabathuler JP, Barras D, Krahenbuhl Y (1992) Evaluation of various processes for the production of billet with thixotropic properties. 2nd international conference on semi-solid processing of alloys and composites. MIT, Cambridge, USA, pp 33–46

Mertens HP, Kopp R, Bremer T, Neudenberger D, Hirt G, Witulski T, Ward P, Kirkwood DH (1997) Comparison of different feedstock materials for thixocasting. EUROMAT 97, Proceedings of the 5th European conference on advanced materials and processes and applications. pp 439–444

Bergsma SC, Tolle MC, Kassner ME, Li X, Evangelista E (1997) Mater Sci Eng A237: 24

Brusethaug S, Voje J (2002) Manufacturing of feedstock for semi-solid processing by chemical grain refinement. 6th international conference on semi-solid processing of alloys and composites, Turin, Italy. pp 451–456

Backerud L, Chai G, Tamminen J (1990) Solidification characteristics of aluminum alloys, Vol 2, foundry alloys. American Foundry Society Inc, Des Plaines, IL

Doutre D, Hay G, Wales (2002) United States Patent No. 6428636, Aug 6, 2002

Lashkari O, Ghomashchi R, Adjersch F (2005) In: Schlesinger ME (ed) Rheological study of 356 Al–Si foundry alloy prepared by a new innovative SSM process. Extraction and Processing Division (EPD), TMS publication, San Francisco, pp 149–156

Pasciak KJ, Sigworth GK (2001) AFS Trans 109

Kurz W, Fisher DJ (1989) Fundamental of solidification. Trans Tech Publication, Switzerland

Apelian D (2002) Semi-solid processing routes and microstructure evolution, 7th international conference on semi-solid processing of alloys and composites, Tsukuba, Japan, 2002. pp 25–30

Chai G, Rolland T, Arnberg L, Backerud L (1992) Studies of dendrite coherency in solidifying aluminum alloy melts by rheological measurements. 2nd international conference on semi-solid processing of alloys and composites, Cambridge, MA. pp 193–201

Lashkari O, Ghomashchi R (2006) The implication of rheological principles for characterization of semi-solid Al–Si cast billets. J Mat Sci (in press)

Chen CP, Tsao CYA (1997) Acta Metal 45(5):1955

Acknowledgements

The work reported here is part of an NSERC-Discovery grant and NSERC-ALCAN-UQAC industrial research chair, Grant No. IRCPJ268528-01, on the “Solidification and Metallurgy of Al-alloys”. The authors would like to gratefully acknowledge financial support from Natural Sciences and Engineering Research Council of Canada, ALCAN International Limited, Centre Québécois de recherche et de développement de l’aluminium (CQRDA), la Fondation de l’UQAC and the endowment fund of UQAC. Joseph Langlais of ALCAN-ARDC, for his continued interest, and Omid Lashkari of our research group, for carrying out the rheological tests, are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Dr. Reza Ghomashchi was Former NSERC-ALCAN-UQAC Professor and Chair holder; Now Director, Advanced Materials and Processing Research Institute, (http://www.ampr-institute.com/).

Shahrooz Nafisi is Research fellow, Facility for Electron Microscopy Research, McGill University, Montreal, Canada.

Rights and permissions

About this article

Cite this article

Nafisi, S., Ghomashchi, R. The effect of dissolved titanium on the primary α-Al grain and globule size in the conventional and semi-solid casting of 356 Al–Si Alloy. J Mater Sci 41, 7954–7963 (2006). https://doi.org/10.1007/s10853-006-0866-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0866-1