Abstract

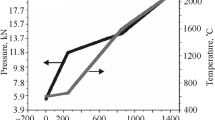

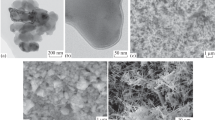

Spark plasma sintering (SPS) is a newly developed technique that enables poorly sinterable aluminum nitride (AlN) powder to be fully densified. It is addressed that pure AlN sintered by SPS has relatively low thermal conductivity. In this work, SPS of AlN ceramic was carried out with Y2O3, Sm2O3 and Li2O as sintering aids. Effects of additives on AlN densification, microstructure and properties were investigated. Addition of sintering aids accelerated the densification, lowered AlN sintering temperature and was advantageous to improve properties of AlN ceramic. Thermal conductivity and strength were found to be greatly improved with the present of Sm2O3 as sintering additive, with a thermal conductivity value about 131 Wm−1K−1 and bending strength about 330 MPa for the 2 wt% Sm2O3-doped AlN sample SPS at 1,780 °C for 5 min. XRD measurement revealed that additives had no obvious effect on the AlN lattice parameters. Observation by SEM showed that AlN ceramics prepared by SPS method manifested quite homogeneous microstructure. However, AlN grain sizes and shapes, location of secondary phases varied with the additives. The thermal conductivity of AlN ceramics was mainly affected by the additives through their effects on the growth of AlN grain and the location of liquid phases.

Similar content being viewed by others

References

Zhou HP, Yao YC, Wu Y (1998) J Chin Ceram Soc 26(4):517

Risbud SH, Shan CH (1995) Mater Sci Eng A204:146

Groza JR, Zavaliangos A (2000) Mater Sci Eng A287:171

Omori M (2000) Mater Sci Eng A287:183

Zhang DM (2002) In: Study on mechanism of pulse electric current sintering of ceramic materials. Dissertation For Doctor’s Degree, Wuhan University of Technology

Qiao L, Zhou HP, Li CW (2003) Mater Sci Eng B99:102

Khor KA, Cheng KH, Yu LG et al (2003) Mater Sci Eng A347:300

Khor KA, Yu LG, Murakoshi Y (2005) J Euro Ceram Soc 25:1057

Jarrige J, Lecompte JP, Mullot J et al (1997) J Euro Ceram Soc 17:1891

Tu YD, Hundere AM, Hoier R et al (2002) J Euro Ceram Soc 22:247

Terao R, Tatami J, Meguro T et al (2002) J Euro Ceram Soc 22:1051

Du S, Liu Z, Li LT et al (1995) Mater Lett 25:105

Qiao L, Zhou HP, Chen KX et al (2003) J Euro Ceram Soc 23:1517

Slack GA (1973) J Phys Chem Solids 34:321

Harris JH, Yongman RA, Teller RG (1990) J Mater Res 5(8):1763

Acknowledgements

This work was supported by National Natural Science Foundation of China (50232020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, M.J., Zhang, L.M., Shen, Q. et al. Microstructure and properties of spark plasma sintered AlN ceramics. J Mater Sci 41, 7934–7938 (2006). https://doi.org/10.1007/s10853-006-0862-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0862-5