Abstract

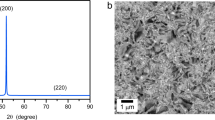

Experiments were conducted on electrodeposited (ED) nanocrystalline (nc) Ni with an average initial grain size of about 20 nm at 393 K to study the shape of the creep curves. In addition, microstructure was examined by means of transmission electron microscopy (TEM). The results show that the creep curves are characterized by the presence of a well-defined steady-state stage. An examination of the microstructure indicates that while grain growth occurs during deformation, the grain size attains a constant value once steady state creep is approached. A comparison between grain size measurements obtained by the TEM technique and those obtained via the X-ray diffraction method shows that the use of the latter method may lead to an underestimation of the value of the average grain size.

Similar content being viewed by others

References

Gleiter H (1989) Prog Mater Sci 33:223

Gleiter H (2000) Acta Mater 48:1

Mohamed FA, Li Y (2001) Mater Sci Eng A 298A:1

Bird JE, Mukherjee AK, Dorn JE (1969) In: Brandon DG, Rosen A (eds) Quantitative relation between properties and microstructures. Israel University Press, Jerusalem, pp 255

Yin WM, Whang SH, Mirshams RA (2005) Acta Mater 53:383

Kottada RS, Chokshi AH (2005) Scripta Mater 53:887

Wang DL, Kong QP, Shui JP (1994) Scripta Metall Mater 31:47

Deng J, Wang DL, Kong QP, Shui JP (1995) Scripta Metall Mater 32:349

Xiao ML, Kong QP (1997) Scripta Mater 36:299

Wang N, Wang Z, Aust KT, Erb U (1997) Mater Sci Eng A 237A:150

Hahn H, Averback RS (1991) J Am Ceram Soc 74:2918

Yin WM, Whang SH, Mirshams RA, Xiao CH (2001) Mater Sci Eng A 301A:18

Dalla Torre F, Spätig P, Schäublin R, Victoria M (2005) Acta Mater 53:2337

Dalla Torre F, Van Swygenhoven H, Schäublin R, Spätig P, Victoria M (2005) Scripta Mater 53:23

Dalla Torre F, Van Swygenhoven H, Victoria M (2002) Acta Mater 50:3957

Kumar KS, Suresh S, Chisholm MF, Horton JA, Wang P (2003) Acta Mater 51:387

Wang YM, Chang S, Wei QM, Ma E, Nieh TG, Hamza A (2004) Scripta Mater 51:1023

Haasz TR, Aust KT, Palumbo G, El-Sherik AM, Erb U (1995) Scripta Metall Mater 32:423

Shei SA, Langdon TG (1978) Acta Metall 26:639

Yan S (1998) PhD Thesis. University of California, Irvine

Chirouze BY, Schwartz DM, Dorn JE (1967) Trans Q AM Soc Metals 60:51

Murty KL, Mohamed FA, Dorn JE (1972) Acta Metall 20:1009

Chauhan M, Mohamed FA (2006) Mater Sci Eng A 427:7

Mackenzie JK, Moore AJW, Nicholas JF (1962) J Phys Chem Solids 23:185

Kulg HP, Alexander LE (1974) Wiley, New York, pp 661

Coble RL (1963) J Appl Phys 34:1679

Wang N, Wang Z, Aust KT, Erb U (1995) Acta Metall Mater 43:519

Conrad H, Narayan J (2000) Scripta Mater 42:1025

Liao XZ, Kilmametov AR, Valiev RZ, Gao H, Li X, Mukherjee AK, Bingert JF, Zhu YT (2006) Appl Phys Lett 88:021909

Shan ZW, Stach EA, Wiezorek JMK, Knapp JA, Follstaedt DM, Mao SX (2004) Science 305:654

Jin M, Minor AM, Stach EA, Morris JW (2004) Acta Mater 52:5381

Acknowledgements

This work was supported by National Science Foundation under Grant number DMR-0304629. Thanks are extended to Dr. Wen-An Chiou, Indranil Roy, and Li-Chung Lai for their assistance in some of the TEM work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chauhan, M., Mohamed, F.A. Microstructural evolution of bulk nanocrystalline Ni during creep. J Mater Sci 42, 1606–1614 (2007). https://doi.org/10.1007/s10853-006-0823-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0823-z