Abstract

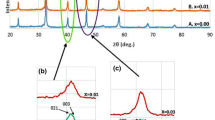

Ba0.9Sr0.1TiO3 powder was processed at 80°C by reacting Ti sol in aqueous solutions that contained BaCl2, SrCl2 and NaOH at atmospheric pressure. Well-crystallized, spherical, nanosizes powders were formed by this method. The powders were found to have a cubic structure, which was retained even after heating at 900°C. Sintering at 1400°C, led to the formation of a tetragonal structure with a secondary phase of Ba6Ti17O40. Abrupt grain growth was observed at 1400°C. The electrical response of the sample sintered at 1400°C has three electrically different regions. Each region of the sample is represented by different RC element. Element 1 (R 1 C 1) is the most resistive and its capacitance ishigh (0.5 nFcm−1) indicating a thin region, probably the grain boundary. Element 2 (R 2 C 2) shows a smaller resistance value compared to element 1. The capacitance value of element 2 is temperature-dependent and displays a Curie–Weiss behaviour, indicative of a ferroelectric material above T c. The lower capacitance of C 2 (15 pFcm−1) indicates that it is a much thicker region than element 1 and can be assigned as a ferroelectric bulk region. Element 3 is probably an electrode effect.

Similar content being viewed by others

References

Haertling GH (1999) J Am Ceram Soc 82:797

Sengupta LC, Ngo E, O’Day ME, Laccto R (1995) Proc. 1994 IEEE 13th Int. Symp. 622

Zhang T, Ni H (2002) Sensor Actuator A 100:252

Whatmore RW (1991) Ferroelectrics 118:241

Khan M, Burks DP, Burn I, Schulze WA (1988) In: Levinson LM (ed) Electronic ceramics. Marcel Dekker, New York, p. 191

Qutzourhit A, Trefny JU, Kito T, Yarar B, Naziripour A, Hermann AM (1995) Thin Solid Films 259:218

Dietz GW, Schumacher M, Waser R, Streiffer SK, Basceri C, Kingon AI (1997) J Appl Phys 82:2359

Jeon JH, Hahn YD, Kim HD (2001) J Euro Ceram Soc 21:1653

Komarneni S, Li QH, Stefansson KM, Roy R (1993) J Mater Res 8:3176

Gallagher PK, Schrey F, DiMarcello FV (1963) J Am Ceram Soc 46:350

Schrey F (1965) J Am Ceram Soc 48:401

Selvam IP, Kumar V (2002) Mater Lett 56:1089

Thakur OP, Prakash C, Agrawal DK (2002) Mater Lett 56:970

Roeder RK, Slamovich EB (1999) J Am Ceram Soc 82:1665

Khollam YB, Bhoraskar SV, Deshpande SB, Potdar HS, Pavaskar NR, Sainkar SR, Date SK (2003) Mater Lett 57:1871

Urban JJ, Yun WS, Gu Q, Park HK (2002) J Am Chem Soc 124:1186

O’Brien S, Brus L, Murray CB (2001) J Am Chem Soc 123:12085

Hernandez BA, Chang KS, Fisher ER, Dorhout PK (2002) Chem Mater 14:480

Perez-Maqueda LA, Dianez MJ, Gotor FJ, Sayagues MJ, Real C, Criado JM (2003) J Mater Chem 13:2234

Urban JJ, Spanier JE, Ouyang L, Yun WS, Park HK (2003) Adv Mater 15:423

Wada S, Tsurumi T, Chikamori H, Noma T, Suzuki T (2001) J Crystal Growth 229:433

Gherardi P, Matijevic E (1988) Colloids Surf 32:257

Cho JH, Kuwabara M (2004) J Euro Ceram Soc 24:2959

Irvine JTS, Sinclair DC, West AR (1990) Adv Mater 2:132

Sinclair DC, Finlay DM, West AR (2000) Int Ceram 2:33

Sinclair DC, West AR (1989) J Appl Phys 66:3850

Srimala S., Ahmad Fauzi MN, Zainal Arifin A, Radzali O (2004) JIMM 5:33

Xia CT, Shi EW, Zhong WZ, Guo JK (1995) J Euro Ceram Soc 15:1171

Moon J, Suvaci E, Li T, Costantino SA, Adair JH (2002) J Euro Ceram Soc 22:809

Testino A, Buscaglia MT, Viviani M, Buscaglia V, Nanni P (2004) J Am Ceram Soc 87:79

Lee SB, Sigle W, Ruhle M (2002) Acta Mater 50:2151

Henning DFK, Janssen R, Reynen PJL (1987) J Am Ceram Soc 70:23

Rios PR, Yamamoto T, Kondo T, Sakuma T (1998) Acta Mater 46:1617

Lee BK, Chung SY, Kang SJL (2000) J Am Ceram Soc 83:2858

Morrison FD, Sinclair DC, Skakle JMS, West AR (1998) J Am Ceram Soc 81:1957

West AR (1984) Solid state chemistry and applications. John Wiley & Sons, Chichester, p. 281

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sreekantan, S., Noor, A.F.M., Ahmad, Z.A. et al. Characterization of Ba0.9Sr0.1TiO3 prepared by low temperature chloride aqueous synthesis. J Mater Sci 42, 2492–2498 (2007). https://doi.org/10.1007/s10853-006-0797-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0797-x