Abstract

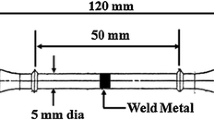

Resistance microwelding of 316L stainless steel to Pt wire has been performed. The interfacial metallurgical phenomena, joint breaking force and fracture mode were investigated using scanning electron microscopy, energy-dispersive X-ray spectroscopy and tensile-shear testing. The results showed that a solid-state bonding was achieved at the interface when the welding current was low and/or the weld time was short, whereas a bonding with fusion of materials was observed at high welding current. Melting of the stainless steel was more significant than that of the Pt wire. The amount of melted materials and bonded area increased with increasing welding current and/or weld time. At a low welding current, e.g., 500 A, all the joints fractured at the interface and the joint breaking force rapidly increased when weld time prolonged from 2 ms to 10 ms owing to increased bonded area. At a medium welding current, e.g., 750 A, the joints demonstrated different fracture mode, e.g., at the interface, a mixed failure at the interface and in the Pt wire as well as completely within the Pt wire, as the weld time increased. On the other hand, at a high welding current, e.g., 1,000 A, the stainless steel was greatly melted and softened into which the Pt wire penetrated and all the joints fractured in the Pt wire. The joint breaking force first increased with increasing weld time and subsequently decreased after reaching a peak value. The effects of materials properties on dissimilar materials resistance welding process were also discussed.

Similar content being viewed by others

References

Sudhakar KV (2005) Eng Failure Anal 12:249

Keun-Taek Oh, Young-Sik Kim, Yong-Soo Park, Kyoung-Nam Kim (2004) J Biomed Mater Res 69B:183

Haynes DR, Crotti TN, Haywood MR (2000) J Biomed Mater Res 49:167

Baba N, Watanabe I, Liu J, Atsuta M (2004) J Biomed Mater Res 69B:121

Noolua NJ, Kerr HW, Zhou Y, Xie J (2005) Mater Sci Eng A 397:8–15

Ferrante M, Pigoretti EV (2002) J Mater Sci 37:2825, Doi: 10.1023/A:1015845822629

Johson KI (1985) Introduction to microjoining. TWI, Abington, United Kingdom

Tan W, Zhou Y, Kerr HW (2002) Metall Mater Trans A 33A:2667

Fukomoto S, Zhou Y Metall (2004) Metall Mater Trans A 35A:3165

Fukomoto S, Chen Z, Zhou Y (2005) Metall Mater Trans A 36A:2717

Dong SJ, Zhou Y (2003) Metall Mater Trans A 34A:1501

Dong SJ, Kelkar GP, Zhou Y (2002) IEEE Trans Electron Packag Manufact 25:355

Zhou Y, Dong SJ, Ely KJ (2001) J Electron Mater 30:1012

Massalski TB (1990) Binary alloy phase diagrams. ASM International, Materials Park, OH

Resistance Welder Manufactures’ Association (RWMA) (1989) Resistance welding manual, 4th edn, George H. Buchanan Co., Philadelphia, Sect 1

Zhou Y, Gorman P, Tan W, Ely KJ (2000) J Electron Mater 29:1090

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z. Joint formation mechanism and strength in resistance microwelding of 316L stainless steel to Pt wire. J Mater Sci 42, 5756–5765 (2007). https://doi.org/10.1007/s10853-006-0671-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0671-x