Abstract

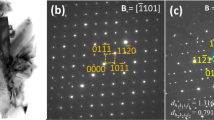

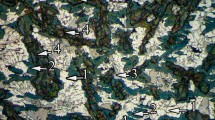

The formation mechanism of spinels on Al2O3 particles in the Al2O3/Al–1.0 mass% Mg2Si alloy composite material has been investigated by transmission electron microscopy (TEM) in order to determine the crystallographic orientation relationship. A thin sample of the Al2O3/Al–Mg–Si alloy composite material was obtained by the FIB method, and the orientation relationship between Al2O3 and MgAl2O4, which was formed on the surface of Al2O3 particles, was discovered by the TEM technique as follows:

At the interface between the Al2O3 and the matrix the MgAl2O4 (spinel) crystals had facets of {111} planes. Spinels were not grown as thin films, but as particles consisting of {111} planes. They grow towards both the matrix and the Al2O3 particles.

Similar content being viewed by others

References

Ikeno S, Araki M, Matsuda K, Shinagawa F, Uetani Y (1999) J Japan Inst Light Metal 49:244

Ikeno S, Matusda K, Teraki T, Terayama K, Rengakuji S, Shinagawa F, Uetani Y (1997) J Japan Inst Light Metal 47:421

Ikeno S, Matsuda K, Rengakuji S, Uetani Y (2001) J Mater Sci 36:1921

Ikeno S, Matsui H, Matsuda K, Uetani Y (2000) Mater Sci Forum 331–337:1193

Ikeno S, Furuta K, Teraki T, Matsuda K, Anada H, Uetani Y (1996) J Japan Inst Light Metals 46:9

Lee KB, Kim YS, Kwon H (1998) Met Mater Trans A 29A:3087

Lu P, Loehman RE, Ewsuk KG, Fahrenholtz WG (1999) Acta Mater 47:3099

Rao BS, Jayaram V (2001) Acta Mater 49:2373

Daoud A, Reif W (2002) J Mater Process Tech 123:313

Thirsk HR, Whitmore EJ (1940) Trans Faraday Soc 36:565

Li DX, Pirouz P, Heuer AH (1992) Phil Mag A 65:403

Carter CB, Schmalzried H (1985) Phil Mag A 52:207

Acknowledgement

Authors thank to Mr. Hiroaki Matsui, formerly Master’s Student, Graduate School, Toyama University, is with Aishin-Keikinzoku Co. Ltd. (Toyama, 934-8588, Japan) for his experimental support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ikeno, S., Matsuda, K., Matsuki, T. et al. The crystallographic orientation relationship between Al2O3 and MgAl2O4 in the composite material Al2O3/Al–Mg–Si alloy. J Mater Sci 42, 5680–5685 (2007). https://doi.org/10.1007/s10853-006-0538-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0538-1