Abstract

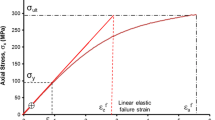

Application of Weibull statistics to tensile strength prediction in laminated composites with open holes is revisited. Quasi-isotropic carbon fiber laminates with two stacking sequences [45/0/−45/90]s and [0/45/90/−45]s with three different hole sizes of 2.54, 6.35 and 12.7 mm were considered for analysis and experimental examination. The first laminate showed 20% lower strength for smaller and 10% for the larger hole sizes. A novel critical failure volume (CFV) method with minimum scaling length constraint as well as the traditional Weibull integral method were applied. The strength prediction was based on the state of stress in the 0° ply by taking into account the redistribution of stress due to matrix damage in the form of splitting, delamination and matrix cracking of off axis plies. The state of matrix damage precipitating failure was recorded by using X-radiography and examined by a sectioning technique. The measured extent of damage was then included in a 3D stress analysis procedure by using a mesh independent crack modeling method to account for fiber direction stress redistribution. The CFV method gave results within one standard deviation from experimentally observed strength values for both laminates and all three hole sizes. The Weibull integral method underpredicted the strength in all cases from as much as 20–30% for smaller hole sizes to 8% for the large holes. The accuracy of failure predictions using CFV is attributed to the introduction of a minimum scaling length. This length has a physical meaning of the width of a process zone of formation of fiber macro-crack as a result of single fiber break interaction. Direct measurement or rigorous evaluation of this parameter is, however, difficult. Consistent with referenced micromechanical studies, its value was assigned equal to six times the Rosen’s ineffective length.

Similar content being viewed by others

References

ASTM D3039/D3039M-00e2. Standard test method for tensile properties of polymer matrix composites. ASTM International, West Conshoken, PA, December, 2000

Whitney JM, Nuismer RJ (1974) J Compos Mate 8:253

Waddoups ME, Eisenmann J and Kaminski BE (1971) J Compos Mater 5:446

Nuismer RJ, Whitney JM (1975) Fract Mech Compos, ASTM STP 593:117

Whitney JM, Kim RY (1976) Effect of stacking sequence on the notched strength of laminated composites, AFML-TR-76-177

Kortshot MT, Beaumont PWR (1990) Compos Sci Technol 39:303

Iarve EV (2003) Int J Mth Eng 56:869

Iarve EV, Mollenhauer DH, Kim R (2005) Compos Part A 36:163

Mollenhauer D, Iarve EV, Kim R, Langley B (2006) Composites: Part A 282:294

Wismon MR (1999) Compos Sci Technol 59:1937

Wisnom MR, Khan B, Green B, Jiang W, Hallet SR (2005) Specimen size effects on tensile strength and failure mechanisms of carbon/epoxy composites. JNC14 Conference, Compiegne, March 2005

Wu EM (1978) Failure analysis of composites with stress gradients, UCRL-80909

Wetherhold RC and Whitney JM (1981) Polymer Compos 2(3):112

Wetherhold RC (1985) J Compos Mater 19:19

Iarve EV, Mollenhauer DH, Kim R (2006) Composites Part A (accepted)

Moes N, Dolbow J and Belytschko T (1999) Int J Numer Methods Eng 46:131

Rosen BW (1964) AIAA J 2:1985

Landis CM, Beyerlin IJ, McMeeking RM (2000) Mech Phys Solids 48:621

Bazant ZP (2002) Scaling of structural strength. Hermes Penton Science (Kogan Page Science), London

Pagano NJ, Schoeppner GA, Kim R, Abrams FL (1998) Compos Sci Technol 58:1811

Acknowledgements

The work was supported by Air Force Research Laboratory through contract number FA8650-05-D-5052 to the University of Dayton Research Institute. The authors are grateful to Chase Nessler of the Southwest Council of Higher Education for performing the sectioning studies.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

Computation of the v(q) function

After the solution is completed and all vectors U ijk are determined, a post-processing step is performed in which each integration point of the structure is examined twice. First the stress and strain components are computed, and the maximum value σ m of the component of interest is found by searching through all integration points. A large number M (in our analysis M = 101 and 201) is then prescribed, and a sequence

defined. The overstressed volume function v(q) is then calculated in M points as

In Eq. (20) indexes g i , i=1,2,3 denote Gauss integration points in x 1, x 2 and x 3 directions, respectively, and w gi are respective Gaussian weights. Heaviside step function (5) cuts off the contribution from all integration points where the stress is lower than the threshold q i σ m . For low values of the threshold value, v(q) will include almost all integration points in (20) and become close to the entire volume.

Appendix 2

Average strength value calculation

For Weibull distribution (8) with shape function (16), the average value of strength σa and the coefficient of variation ω (standard variation divided by average value) are given by well known equations:

where Γ-denotes the gamma function. By using Eq. (21a), one can find the average strength value for a known α if the probability of failure is known for just for one value of σ, i.e. f is equal to f 1 for σ = σ1. In this case

Equation (22) will be used to calculate the average strength for both the Weibull integral and CFV method based estimates of the probability of failure.

Rights and permissions

About this article

Cite this article

Iarve, E.V., Mollenhauer, D., Whitney, T.J. et al. Strength prediction in composites with stress concentrations: classical Weibull and critical failure volume methods with micromechanical considerations. J Mater Sci 41, 6610–6621 (2006). https://doi.org/10.1007/s10853-006-0200-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0200-y