Abstract

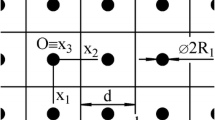

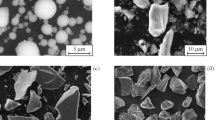

The paper deals with elastic thermal stresses in an isotropic multi-particle-matrix system consisted of periodically distributed spherical particles in an infinite matrix, imaginarily divided into cubic cells containing a central spherical particle. Originating during a cooling process as a consequence of the difference in thermal expansion coefficients between the matrix and the particle, and investigated within the cubic cell, the thermal stresses, as functions of the particle volume fraction v, being transformed for v = 0 to those of an isotropic one-particle-matrix system, are maximal at the critical particle volume fraction, representing a considerable value related to maximal resistance of the thermal-stress strengthened multi-particle-matrix system against mechanical loading. The thermal stresses are derived for such temperature range within which the multi-particle-matrix system exhibits elastic deformations, considering the yield stress and the particle-matrix boundary adhesion strength. With regard to a curve integral of the thermal-stress induced elastic energy density, critical particle radii related to crack initiation in ideal-brittle particle and matrix, functions describing crack shapes in a plane perpendicular to the direction of crack formation in the particle and in the matrix, and consequently dimensions of a crack in the particle and in the matrix are derived along with the condition concerning the direction of the crack formation. Additionally, derived by two equivalent mathematical techniques, the elastic energy gradient within the cubic cell, representing a surface integral of the thermal-stress induced elastic energy density, is presented to derive the thermal-stress induced strengthening in the spherical particle and in the cubic cell matrix. The former parameters for v = 0 are derived using the model of a spherical cell with the radius \({R_c\rightarrow\infty}\). Derived formulae are applied to the SiC–Si3N4 multi-particle-matrix system, and calculated values of investigated parameters are in a good agreement with those from published experimental results.

Similar content being viewed by others

References

Ivančo V, Kubín K, Kostolný K (1994) In: Finite element method I. Elfa, Košice, Slovak Republic, p 36 (in Slovak)

Hvizdoš P, Lofaj F, Dusza K (1995) Metall Mater 33:473

Besterci M, Velgošová O, Lofaj F (2003) Acta Mech Slovaca 4:47

Diko P (1998) Supercond Sci Technol 11:68

Diko P (1998) Mater Sci Eng B 83:149

Janovec J, Magula V, Holý A, Výrostková A (1992) Scripta Metall Mater 26:1303

Janovec J, Výrostková A, Svoboda M (1994) Metall Mater Trans A25:267

Sidor Y, Kováč F, Novák L, Kravčák (2002) J Acta Electrotech Inform 2(3):96

Sidor Y, Kováč F, Petrychka V (2004) Acta Metall Slovaca 10:698

Petrychka V, Kováč F, Sidor Y (2004) Acta Metall Slovaca 10:702

Skočovský P, Bokůvka O, Konečná R, Tillová E (2001) In: Science on materials for mechanical engineers. EDIS Technical University in Žilina, Žilina, Slovak Republic, p 252 (in Slovak)

Mizutani T (1996) J Mater Res 11:483

Ceniga L (2004) J Thermal Stresses 27:425

Ceniga L (2005) In: Caruta BM (ed) New developments in material science research. Nova Science Publishers, New York, USA, ISBN: 1-59454-793-9

Ceniga L, Kováč F (2001) Mater Sci Eng B86:178

Pánek Z, Figusch V, Haviar M, Ličko T, Šajgalík P, Dusza J (1992) In: Structural ceramics. R&D. Bratislava, Slovak Republic, p 27 (in Slovak)

Kluvánek I, Mišík L, Švec M (1959) In: Mathematics I. Alfa, Bratislava, Slovak Republic, p 685 (in Slovak)

Zimovčák P, Köves T, Dusza J, Chalvet F, Portu G (2005) Key Mater Eng 290:264

Acknowledgements

This work was supported by the Slovak Grant Agency VEGA (2/7197/27, 2/7194/27, 2/7195/27), by NANOSMART, Centre of Excellence, Slovak Academy of Sciences, by Science and Technology Assistance Agency under the contract No. APVV-20-061505, APVV-20-024405, by RTN2-2001-00488 SICMAC, by 2003 SO 51/03R8 06 00/03R 06 03-2003, by EU 5th FP project No. GRD1-2000-25352 “SmartWeld”, by COST Action 536 and COST Action 538, by T043704 OTKA foundation, by János Bolyai Research Grant NSF-MTA-OTKA grant MTA: 96/OTKA: 049953.

Author is thankful to his dearest parents for their support.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The elastic moduli of the particle (q = p) and the matrix (q = m), s q , have the forms

where E q and μ q are the Young’s modulus and Poisson’s number, respectively.

The coefficient c is derived as

where the coefficient c 3 can be derived by the Taylor series for the integrated function. Consequently, after integration of the Taylor series in terms of \({\left(\varphi-\varphi_0\right)^n}\) about the point \({\varphi_0=0}\), the coefficient \({c_3=0.337497}\) for n = 100;

where the coefficient c 11 for \({x_1\in\left(0,d/2\right\rangle}\) can be derived for a concrete isotropic particle-matrix system by the Taylor series for the integrated function in terms of \({\left(\xi-\xi_0\right)^n}\) about the point \({\xi_0=0}\);

where the coefficient c 13 can be derived for a concrete isotropic particle-matrix system by the Taylor series for the integrated function in terms of \({\left(\varphi-\varphi_0\right)^n}\) about the point \({\varphi_0=0}\);

Rights and permissions

About this article

Cite this article

Ceniga, L. Thermal stresses and related phenomena in composite ceramics. J Mater Sci 42, 1202–1227 (2007). https://doi.org/10.1007/s10853-006-0094-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0094-8