Abstract

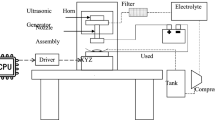

This article presents the development of an innovative approach using the vacuum submerged arc machining with aid of enhanced ultrasonic vibration to manufacture nanoparticles. The Arc Spray Nanoparticle Synthesis System (ASNSS) previously designed by the NTUT’s Nano Laboratory has been successfully developed to generate nanoparticles. In this proposed process, a titanium bar, as the electrode, is melted and vaporized in distilled water, used as an insulating liquid. Meanwhile, the ultrasonic vibration is applied to the electrode to remove the vaporized metal powders rapidly from the melting zone. The vaporized metal particles are then rapidly quenched by the designed cooling system, thus nanocrystalline particles nucleated and formed. This study discusses the the influence of the ultrasonic amplitude and various process variables such as pulse duration, peak current, and dielectric liquid temperature on TiO2nanoparticles suspension.

Similar content being viewed by others

References

Kubo, J. Phys. Soc. Japan 17 (1962) 975.

H. Froes and C. Sruyanarayana, JOM June (1989) 12.

R. Birringen, Mater. Sci. Engng. A117 (1989) 33.

R. P. Andres and R. S. Arerback, et al., J. Mater. Res. 4(3) (1989) 704.

J. S. Soni, Wear 177 (1994) 71.

P. Willey, in Proc. IEE Conf., Electromethods of Machining, Forming and Coating (1975) p. 265.

V. S. R. Murti and P. K. Philip, Wear 117(2) (1987) 241.

J. S. Soni and G. Chakraverti, in Proc. AMPT 1993 Conf. (Dublin, Ireland, 1993) p. 755.

T. T. Tsung, H. Chang, L. C. Chen, L. L. Han, C. H. Lo and M. K. Liu, Jpn. Inst. Metals 44 (2003) 1138.

H. Chang, T. T. Tsung, L. C. Chen, Y. C. Yang, H. M. Lin, L. L. Han and C. K. Lin, Jpn. Inst. Metals 45 (2004) 806.

X. M. Dai and J. L. Wang, Chinese Powder Technology 5(6) (1999) 28.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, H., Tsung, TT., Lo, CH. et al. A study of nanoparticle manufacturing process using vacuum submerged arc machining with aid of enhanced ultrasonic vibration. J Mater Sci 40, 1005–1010 (2005). https://doi.org/10.1007/s10853-005-6520-5

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-6520-5