Abstract

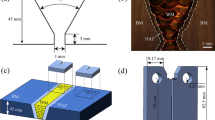

Solid state transition joints made, by cold extrusion, between steel and Cu powder metallurgical (P/M) preform tubes were heat treated at various temperatures and time, with and without interlayer, to evaluate the weld strength and microstructural characteristics. Post-joining heat treatments lead to different recrystallized structures near the interface due to strain localization and solute drag effect. The strain localization and residual porosity in the joints enhanced void formation in the diffusion zone when the interlayer was absent. Coarse Ni powder as an interlayer reduced the weld strength due to physical discontinuities and residual particles at the interface, after heat treatment. On the other hand, finer Ni powder improved the weld strength. Use of 1 μm Ni interlayer in combination with optimal heat treatment conditions (950°C for 2 h) resulted in about 45% increase in weld strength.

Similar content being viewed by others

References

N. BAY, J. Eng. Ind., Trans. ASME 101(5) (1979) 121.

R. DUBROVSKY, Advances in Welding Science and Technology—TWR '86: in Proc. International Conference on Trends in Welding Research (1986) Gatlinburg, TN, USA, pp. 745.

F. A. CALVO, A. URENA, J. M. GOMEZ DE SALAZAR and F. MOLLEDA, J Matl. Sci. 23(6) (1988) 2273.

F. A. CALVO, A. URENA, J. M. GOMEZ DE SALAZAR, F. MOLLEDA and A. J. CRIADO, J Matl. Sci. 23(4) (1988), 1231.

O. A. KATRUS, A. V. ALESHINA, V. K. GRIBKOV and V. M. OCHERETYANSKII, Soviet Powder Metallurgy and Metal Ceramics (English translation of Poroshkovaya Metallurgiya) 23(5) (1984) 370.

ASM Hand Book, in ‘Alloy Phase Diagrams’ (ASM International, Metals Park, Ohio, 1992), Vol. 3.

M. ABBASI, A. KARIMI TAHERI and M. T. SALEHI, J. Alloys and Comp. 319 (2001) 233.

Y. OSMAN and A. MUSTAFA, J. Matl. Proc. Tech. 121 (2002) 136.

R. A. MASUMURA, B. B. RATH and C. S. PANDE, Acta Mater. 50 (2002) 4535.

D. K. MATLOCK CHOI and D. L. OLSON, Matl. Sci. Eng. A124 (1990) L15.

L. MENG, S. P. ZHOU, F. T. YANG and D. Z. LIN, Matl. Res. Bull 36 (2001) 1726.

L. MENG, S. P. ZHOUM, F. T. YANG, Q. J. SHEN and M. S. LIU, Matl. Char. 47 (2001) 269.

H. NISHI, T. ARAKI and M. ETO, Fusion Engg. Des. 39/40 (1998) 505.

G. B. KALE, R. V. PATIL and P. S. GAWADE, J Nucl. Mater. 257 (1998) 44.

M. GHOSH and S. CHATTERJEE, Matl. Char. 48 (2002) 393.

PENG H E, J. ZHANG, R. ZHOU and X. LI, Matl. Char. 43 (1999) 287.

N. ORHAN, T. I. KHAN and M. EROGLU, Scr. Mater. 45 (2001) 441.

B. ALEMAN, I. GUTIERREZ and J. J. URCOLA, Matl. Sci. Tech. 9 (1993) 633.

H. KATO, M. SHIBATA and K. YOSHIKAWA, Matl. Sci. Tech. 2 (1986) 405.

JIANGWEI REN, YAJIANG LI and FENG TAO, Matl. Lett. 56 (2002) 647.

P. HE, J. C. FENG, B. G. ZHANG and Y. Y. QIAN, Matl. Char. 48 (2002) 401.

B. VAMSI KRISHNA, P. VENUGOPAL and K. PRASAD RAO, Matl. Sci. and Engg. A386 (2004) 301.

P. J. ROSS, in Taguchi Techniques for Quality Engineering, (McGraw-Hill, New York, 1988).

A. KARA-SLIMANE, D. JUVE, E. LEBLOND and D. TREHEUX, J Euro. Cer. Soc. 20 (2000) 1829.

K. D. LEEDY and J. F. STUBBINS, Matl. Sci. Engg. A297 (2001) 10.

T. TABATA and S. MASAKI, Int. J Powder Met. & Powder Tech. 15(3) (1979) 239.

T. TABATA, S. MASAKI and H. SUZUKI, Int. J Powder Met. 25(1) (1989) 37.

T. TABATA, S. MASAKI and K. AZEKURA, Matl. Sci. Tech. 5(3) (1989) 377.

D. DURGALAKSHMI, B. VAMSI KRISHNA, P. VENUGOPAL and D. R. G. ACHAR, J. Matl. Proc. Tech. 132(1–3) (2003) 293.

B. VAMSI KRISHNA, P. VENUGOPAL and K. PRASAD RAO, Trans. Indian Inst. Met. 56(4) (2003) 363.

B. VAMSI KRISHNA, K. PRAVEEN, P. VENUGOPAL and K. PRASAD RAO, International Heat Treat 2004, 9–10 January, 2004, Chennai, India (2004) A8, p1.

Y. HUANG, N. RIDLEY, F. J. HUMPHREYS and J. Z. CUI, Matl. Sci. Engg. A266 (1999) 195.

R. LE GALL and J. J. JONNAS, Acta Mater. 47(17) (1999) 4365.

R. D. DOHERTY, D. A. HUGHES, F. J. HUMPHREYS, J. J. JONAS, D. JUUL JENSEN, M. E. KASSNER, W. E. KING, T. R. MCNELLEY, H. J. MCQUEEN and A. D. ROLLETT, Matl. Sci. Engg. A238 (1997) 219.

D. B. BUTRYMOWICZ, J. R. MANNINA and M. E. READ, in “Diffusion Rate Data and Mass Transport Phenomena for Copper Systems, International Copper Research Association”, (Washington, 1977), p. 177.

R. S. BARNES, Proc. Phys. Soc. London, Sect. B 65 (1952) 512.

R. W. BALLUFFI and L. L. SEIGLE, Acta Metall. 3 (1955) 170.

F. SEITZ, Acta Metall. 1 (1953) 355.

R. W. BALLUFFI, Acta Metall. 2 (1954) 194.

R. S. BARBES and D. J. MAZEY, Acta Metall. 6 (1958) 1.

R. RESNICK and L. SEIGLE, Trans. Metall. Soc. AIME 20 (1957) 87.

RANJAN and G. S. UPADHYAYA, Materi. Design 22 (2001) 359.

E. A. BRANDS and G. B. BROOK, in Smithells Metals Reference Book, 7th ed., (Butterworth-Heinemann, Oxford, 1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krishna, B.V., Venugopal, P. & Prasad Rao, K. Solid state joining of steel-Cu P/M preform tubes: use of interlayer and post joining heat treatments. J Mater Sci 41, 1175–1185 (2006). https://doi.org/10.1007/s10853-005-3655-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-3655-3