Abstract

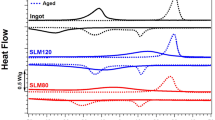

Metal injection molding (MIM) was applied for the production of shape memory parts using prealloyed NiTi powders with different Ni contents as starting materials. The MIM process allows the production of near-net-shape components without the occurrence of rapid tool wear as found in the case of conventional machining operations. With optimized manufacturing conditions, including feedstock preparation, injection parameters and sintering conditions, densities of more than 98% of the theoretical value could be achieved. Determination of the phase transformation behavior, as a basic requirement for the shape memory effect, was done by differential scanning calorimetry (DSC). In a first approach, tensile tests in the austenitic state showed pseudoelastic behavior. An elongation at failure of 3.8% was found. For martensite, up to 5% was obtained. Reasons for the lower strain compared to melted NiTi alloys are discussed. For martensitic samples the one-way shape memory effect (1WE) was demonstrated.

Similar content being viewed by others

References

E. Hornbogen, Metall 41 (1987) 488.

H. Funakubo, in “Shape memory alloys”, (Gordon and Breach Science Publishers, New York, 1987) p. 200.

J. van Humbeeck, R. Stalmans and P. A. Besselink in “Metals as Biomaterials”, edited by J. A. Helsen, H. J. Breme, (John Wiley & Sons, Chichester, 1998) p. 73.

L. Bataillad, J. -E. Didaux and R. Gotthardt, Phil. Mag. A 78 (1998) 327.

J. Khalil-Allafi, X. Ren and G. Eggeler, Acta Mater. 50 (2002) 793.

W. Tang, B. Sundman, R. Sandström and C. Qui, ibid. 47 (1999) 3457.

A. Ishida, M. Sato, A. Takei, K. Nomura and S. Miyazaki, Metall. Mater. Trans. 27A (1996) 3753.

K. Gall, K. Juntunen, H. J. Maier, H. Sehitoglu and Y. I. Chumlyakof, Acta Mater. 49 (2001) 3205.

Y. Shugo, S. Hanada and T. Honma, Bull. Res. Inst. Min. Dress. Metall. Tohuku Univ. 41 (1985) 35.

T. Honma, in “Shape memory alloys”, edited by H. Funakubo, (Gordon and Breach Science Publishers, New York, 1987) p. 61.

P. Olier, F. Barcelo, J. L. Bechade, J. C. Brachet, E. Lefevre and G. Guenin, J. Phys. IV France 7 (1997) C5-143.

S. K. Wu, H. C. Lin and C. C. Chen, Mat. Letters 40 (1999) 27.

H. Kato, T. Koyari, M. Tokizane and S. Miura, Acta metall. Mater. 42 (1994) 1351.

M. D. McNeese, D. C. Lagoudas and T. C. Pollock, Mater. Sci. Eng. A280 (2002) 334.

M. Bram, A. Ahmand-Khanlou, A. Heckmann, B. Fuchs, H. P. Buchkremer and D. Stöver, Mater. Sci. Eng. A337 (2002) 254.

R. M. German, Powder Injection Molding, Metal Powder Industries Federation, Princeton, (1990).

J. W. Newkirk, J. A. Sago and G. M. Brasel, in Processing and Fabrication of Advanced Materials VII, edited by T. S. Srivatsan and K. A. Khor, The Minerals, Metals and Materials Society, Warrendale, (1998) 213.

H. Kyogoku and S. Komatsu, J. Jap. Soc. Powder and Powder Metallurgy 46 (1999) 1103.

B. Y. Li, L. J. Rong., Y. Y. Li and V. E. Gjunter, Acta Mater. 48 (2000) 3895.

S. M. Green, D. M. Grant and N. R. Kelly, Powder Metall. 40 (1997) 43.

C. M. Chang, S. Trigwell and T. Duerig, Surf. Interf. Anal. 15 (1990) 349.

C. L. Chu, S. K. Wu and Y. C. Yen, Mater. Sci. Eng. A 216 (1996) 193.

W. Xiaoxiang, Trans. Nonferrous Met. Soc. China 8 (1998) 455.

D. Treppmann, Thermomechanische Behandlung von NiTi, Fortschrittsberichte VDI, VDI Verlag Dortmund (1997).

X. Ren, N. Miura, J. Zhang, K. Otsuka, K. Tanaka, M. Koiwa, T. Suzuki, Y. I. Chumlyakov and M. Asai, Mater. Sci. Eng. A 312 (2001) 196.

J. Khalil-Allafi, A. Dlouhy and G. Eggeler, Acta Mater. 50 (2002) 4255.

E. Schüller, M. Bram, O. A. Hamed, D. Sebold, H. P. Buchkremer and D. Stöver, to be published, Adv. Eng. Mat.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schöller, E., Krone, L., Bram, M. et al. Metal injection molding of shape memory alloys using prealloyed NiTi powders. J Mater Sci 40, 4231–4238 (2005). https://doi.org/10.1007/s10853-005-2819-5

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-2819-5