Abstract

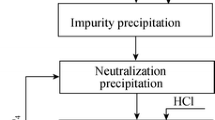

The increasing demands for indium in recent years require high purity indium as raw materials. Physical-chemical purification and electrorefining have been performed to obtain 6N high purity indium. Indium is smelted by using NaOH, NaCl and NaNO3 for 20 min at 400°C, the removing rate of Sn, Zn, Al reaches 40, 60 and 37% respectively. The removing rate of Cd is 90–95% and that of Tl reaches 40–60% when indium is smelted for 10 min by 20% glycerin solution of KI and I2 at 180°C. When indium metal is vacuum refined in two stages: 800–900°C for 2 h and 950–1050°C for 2 h, the major impurity elements, Pb, Zn, and Bi, are effectively removed. When indium is electrolytic refined in In2(SO4)3-H2SO4 system, in which indium content is 60–80 g/L, pH 2.0–3.0, current density 50–80 A/m2, the content of impurities can be dropped and the product of indium reaches 99.9999%.

Similar content being viewed by others

References

LIU SHI-YOU, J. Non-Ferrous Metals. 2 (1999)30.

M. F. MCNAMARA, J. A. SLATTERY and A. F. WITT, US Patent 4,828,608.

OKAMOTO HIDENORI and TAKEBA YASHI KAZUAKI, US Patent 5,543,031.

M. S. SU, J. S. GENTRY and C. B. BOSS, J. Electrochem Soc. 4 (1985) 802.

HAN HAN-MING, J. World of Chemistry. 4 (1995) 174.

ALEXANDER and LAVICT, US 3,268,426.

L. ROWINSKA and L. WALIS, J. Less-common. Met. 1 (1990) 117.

M. G. PITT and D. FRAY, Trans-Inst.Min Metall. Sect.C. 6 (1981) 84.

A. A. OMEL'CHUK, V. T. MELEKHIN and O. G. ZARUBITSKIJ, J. Zhurnal Prikladnoj Khimii. 5 (1998) 772.

B. S. MEDOEV, N. I. KALOEV and A. P. ALIKHANOVA, IZV. Vyssh. Vcheb. Zaved Khim. Teknol. 11 (1980)1339.

HABUKA HITOSHI and HITOSHI FUTAKI, Jp 63,250,428.

A. A. BELSKII, A. V. ELYUTIN and ZUBKOV, US Patent 4,287,030.

LEE MAN-SEUNG, AHN JONG-GWAN and OH YOUNG-JOO, J. Mater. Trans. 12 (2002) 3195.

ZHOU ZHI-HUA, ZENG DONG-MING and SHU WAN-GEN, J. Chinese J. Nonferr. Metals. 2 (2003)522.

ZENG DONG-MING, ZHOU ZHI-HUA and SHU WAN-GEN, J. Chinese J. Rare Metals. 2 (2001)147.

ZHOU ZHI-HUA, ZENG DONG-MING and SHU WAN-GEN, ibid. 6 (2001) 478.

WEI CHANG and LUO TIANJIAO, ibid. 6 (2003) 852.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, ZH., Ruan, JM. & Mo, HB. Preparation of 6N high-purity indium by method of physical-chemical purification and electrorefining. J Mater Sci 40, 6529–6533 (2005). https://doi.org/10.1007/s10853-005-1817-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-1817-y