Abstract

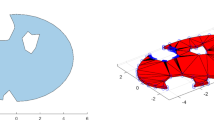

Given a part design, the task of manufacturing process selection chooses an appropriate manufacturing process to fabricate it. Prior research has traditionally determined manufacturing processes through direct classification. However, an alternative approach to select a manufacturing process for a new design involves identifying previously produced parts with comparable shapes and materials and learning from them. Finding similar designs from a large dataset of previously manufactured parts is a challenging problem. To solve this problem, researchers have proposed different spatial and spectral shape descriptors to extract shape features including the D2 distribution, spherical harmonics (SH), and the Fast Fourier Transform (FFT), as well as the application of different machine learning methods on various representations of 3D part models like multi-view images, voxel, triangle mesh, and point cloud. However, there has not been a comprehensive analysis of these different shape descriptors, especially for part similarity search aimed at manufacturing process selection. To remedy this gap, this paper presents an in-depth comparative study of these shape descriptors for part similarity search. While we acknowledge the importance of factors like part size, tolerance, and cost in manufacturing process selection, this paper focuses on part shape and material properties only. Our findings show that SH performs the best among non-machine learning methods for manufacturing process selection, yielding 97.96% testing accuracy using the proposed quantitative evaluation metric. For machine learning methods, deep learning on multi-view image representations is best, yielding 99.85% testing accuracy when rotational invariance is not a primary concern. Deep learning on point cloud representations excels, yielding 99.44% testing accuracy when considering rotational invariance.

Similar content being viewed by others

References

Angrish, A., Bharadwaj, A., & Starly, B. (2020). MVCNN++: Computer-aided design model shape classification and retrieval using multi-view convolutional neural networks. Journal of Computing and Information Science in Engineering. https://doi.org/10.1115/1.4047486

Bruna, J., Zaremba, W., Szlam, A., & LeCun, Y. (2013). Spectral networks and locally connected networks on graphs, International Conference on Learning Representations (ICLR), Banff, Canada.

Cao, W., Robinson, T., Hua, Y., Boussuge, F., Colligan, A. R., & Pan, W. (2020). Graph representation of 3D CAD models for machining feature recognition with deep learning. ASME 2020 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference.

Fang, Y., Xie, J., Dai, G., Wang, M., Zhu, F., Xu, T., & Wong, E. (2015). June 7–12, 2015). 3D Deep Shape Descriptor Proceedings of the IEEE conference on computer vision and pattern recognition, Boston, Massachusetts, USA.

Feng, S. C., & Song, E. Y. (2003). A manufacturing process information model for design and process planning integration. Journal of Manufacturing Systems, 22(1), 1–15. https://doi.org/10.1016/S0278-6125(03)90001-X.

Goodfellow, I., Bengio, Y., & Courville, A. (2016). Deep learning. MIT Press.

Gupta, S. K., Chen, Y., Feng, S., & Sriram, R. (2003). A system for generating process and material selection advice during embodiment design of mechanical components. Journal of Manufacturing Systems, 22(1), 28–45. https://doi.org/10.1016/S0278-6125(03)90003-3.

He, K., Zhang, X., Ren, S., & Sun, J. (2016). Deep residual learning for image recognition, Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA.

Hoefer, M. J., & Frank, M. C. (2018). Automated manufacturing process selection during conceptual design. Journal of Mechanical Design, 140(3), 031701. https://doi.org/10.1115/1.4038686

Ip, C. Y., & Regli, W. C. (2006). A 3D object classifier for discriminating manufacturing processes. Computers & Graphics, 30(6), 903–916. https://doi.org/10.1016/j.cag.2006.08.013.

Jayanti, S., Kalyanaraman, Y., Iyer, N., & Ramani, K. (2006). Developing an engineering shape benchmark for CAD models. Computer-Aided Design, 38(9), 939–953. https://doi.org/10.1016/j.cad.2006.06.007.

Jeschke, S., Brecher, C., Meisen, T., Özdemir, D., & Eschert, T. (2017). Industrial internet of things and cyber manufacturing systems. In S. Jeschke, C. Brecher, H. Song, & D. B. Rawat (Eds.), Industrial internet of things: Cybermanufacturing systems (pp. 3–19). Springer.

JungHyun, H., Pratt, M., & Regli, W. C. (2000). Manufacturing feature recognition from solid models: A status report. IEEE Transactions on Robotics and Automation, 16(6), 782–796. https://doi.org/10.1109/70.897789.

Kailath, T. (1967). The divergence and bhattacharyya distance measures in signal selection. IEEE Transactions on Communication Technology, 15(1), 52–60.

Kazhdan, M., Funkhouser, T., & Rusinkiewicz, S. (2003). Rotation invariant spherical harmonic representation of 3D shape descriptors. Proceedings of the 2003 Eurographics/ACM SIGGRAPH symposium on Geometry processing, Aachen, Germany.

Kazmi, I. K., You, L., & Zhang, J. J. (2013). A survey of 2D and 3D shape descriptors. 2013 10th International Conference Computer Graphics, Imaging and Visualization, Los Alamitos, CA, USA.

Kim, S., Chi, H., Hu, X., Huang, Q., & Ramani, K. (2020). A large-scale annotated mechanical components benchmark for classification and retrieval tasks with deep neural networks. Computer Vision–ECCV 2020: 16th European Conference, Glasgow, UK, August 23–28, 2020, Proceedings, Part XVIII 16.

Kipf, T., & Welling, M. (2017). Semi-Supervised Classification with Graph Convolutional Networks International Conference on Learning Representations (ICRL), Toulon, France.

LeCun, Y., Bengio, Y., & Hinton, G. (2015). Deep learning. Nature, 521(7553), 436–444. https://doi.org/10.1038/nature14539.

Lee, J., Bagheri, B., & Jin, C. (2016). Introduction to cyber manufacturing. Manufacturing Letters, 8, 11–15. https://doi.org/10.1016/j.mfglet.2016.05.002.

Li, Y., Bu, R., Sun, M., Wu, W., Di, X., & Chen, B. (2018). PointCNN: Convolution on x-transformed points, Conference on Neural Information Processing Systems, Montreal, Canada.

Liu, Y., Fan, B., Xiang, S., & Pan, C. (2019). Relation-shape convolutional neural network for point cloud analysis Proceedings of the IEEE conference on computer vision and pattern recognition, Long Beach, CA, USA.

Maturana, D., & Scherer, S. (2015). VoxNet: A 3D convolutional neural network for real-time object recognition International Conference on Intelligent Robots and Systems, Hamburg, Germany.

Niepert, M., Ahmed, M., & Kutzkov, K. (2016). Learning convolutional neural networks for graphs International conference on machine learning, New York City, NY, USA. https://proceedings.mlr.press/v48/niepert16.html.

Ning, F., Shi, Y., Cai, M., & Xu, W. (2021). Part machining feature recognition based on a deep learning method. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-021-01827-7.

Nussbaumer, H. J. (1981). The fast fourier transform. In Fast Fourier Transform and Convolution Algorithms (pp. 80–111). Springer Berlin Heidelberg. https://doi.org/10.1007/978-3-662-00551-4_4.

Osada, R., Funkhouser, T., Chazelle, B., & Dobkin, D. (2002). Shape distributions. ACM Transactions on Graphics, 21(4), 807–832. https://doi.org/10.1145/571647.571648.

Qi, C. R., Su, H., Mo, K., & Guibas, L. J. (2017a). PointNet: Deep learning on point sets for 3D classification and segmentation Proceedings of the IEEE conference on computer vision and pattern recognition, Hawaii, HI, USA.

Qi, C. R., Yi, L., Su, H., & Guibas, L. J. (2017b). PointNet++: Deep hierarchical feature learning on point sets in a metric space Conference on Neural Information Processing Systems, Long Beach, CA, USA.

Riegler, G., Ulusoy, A. O., & Geiger, A. (2017). OctNet: Learning deep 3D representations at high resolutions Proceedings of the IEEE conference on computer vision and pattern recognition, Honolulu, Hawai, USA.

Shi, P., Qi, Q., Qin, Y., Scott, P. J., & Jiang, X. (2020). A novel learning-based feature recognition method using multiple sectional view representation. Journal of Intelligent Manufacturing, 31(5), 1291–1309. https://doi.org/10.1007/s10845-020-01533-w.

Shi, P., Qi, Q., Qin, Y., Scott, P. J., & Jiang, X. (2021). Intersecting machining feature localization and recognition via single shot multibox detector. IEEE Transactions on Industrial Informatics, 17(5), 3292–3302. https://doi.org/10.1109/TII.2020.3030620

Su, H., Maji, S., Kalogerakis, E., & Learned-Miller, E. (2015). Multiview convolutional neural networks for 3D shape recognition International Conference on Computer Vision, Santiago, Chile.

Sun, J., Ovsjanikov, M., & Guibas, L. (2009). A concise and provably informative multi-scale signature based on heat diffusion. Computer Graphics Forum, 28(5), 1383–1392. https://doi.org/10.1111/j.1467-8659.2009.01515.x

Swift, K. G., & Booker, J. D. (2013). Manufacturing process selection handbook: From design to manufacture. Butterworth-Heinemann.

Tolio, T. A. M., Monostori, L., Váncza, J., & Sauer, O. (2023). Platform-based manufacturing. CIRP Annals, 72(2), 697–723.

Verma, A. K., & Rajotia, S. (2010). A review of machining feature recognition methodologies. International Journal of Computer Integrated Manufacturing, 23(4), 353–368. https://doi.org/10.1080/09511921003642121.

Wang, Z., Melkote, S., & Rosen, D. W. (2023). Generative design by embedding topology optimization into conditional generative adversarial network. Journal of Mechanical Design. https://doi.org/10.1115/1.4062980

Wang, Z., & Rosen, D. (2022). Manufacturing process classification based on heat kernel signature and convolutional neural networks. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-022-02009-9.

Wang, Z., & Rosen, D. (2023). Manufacturing process classification based on distance rotationally invariant convolutions. Journal of Computing and Information Science in Engineering. https://doi.org/10.1115/1.4056806

Wei, X., Yu, R., & Sun, J. (2020). View-GCN: View-based graph convolutional network for 3D shape analysis Proceedings of the IEEE conference on computer vision and pattern recognition, Virtual.

Wu, D., Greer, M. J., Rosen, D. W., & Schaefer, D. (2013). Cloud manufacturing: Strategic vision and state-of-the-art. Journal of Manufacturing Systems, 32(4), 564–579.

Wu, D., Rosen, D. W., Wang, L., & Schaefer, D. (2015). Cloud-based design and manufacturing: A new paradigm in digital manufacturing and design innovation. Computer-Aided Design, 59, 1–14. https://doi.org/10.1016/j.cad.2014.07.006.

Yan, X., & Melkote, S. (2022). Generative modeling of the shape transformation capability of machining processes. Manufacturing Letters, 33, 794–801. https://doi.org/10.1016/j.mfglet.2022.07.098

Yan, X., Wang, Z., Bjorni, J., Zhao, C., Dinar, M., Rosen, D., & Melkote, S. (2023). Process-aware part retrieval for cyber manufacturing using unsupervised deep learning. CIRP Annals, 72(1), 397–400. https://doi.org/10.1016/j.cirp.2023.03.020.

Yeo, C., Kim, B. C., Cheon, S., Lee, J., & Mun, D. (2021). Machining feature recognition based on deep neural networks to support tight integration with 3D CAD systems. Scientific Reports, 11(1), 22147. https://doi.org/10.1038/s41598-021-01313-3.

Yu, T., Meng, J., & Yuan, J. (2018). Multi-View Harmonized Bilinear Network for 3D Object Recognition Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, Utah, USA.

Zaman, U. K. U., Rivette, M., Siadat, A., & Mousavi, S. M. (2018). Integrated product-process design: Material and manufacturing process selection for additive manufacturing using multi-criteria decision making. Robotics and Computer-Integrated Manufacturing, 51, 169–180. https://doi.org/10.1016/j.rcim.2017.12.005.

Zhang, D., & Lu, G. (2004). Review of shape representation and description techniques. Pattern Recognition, 37(1), 1–19. https://doi.org/10.1016/j.patcog.2003.07.008.

Zhang, Y., Zhang, Y., He, K., Li, D., Xu, X., & Gong, Y. (2021). Intelligent feature recognition for STEP-NC-compliant manufacturing based on artificial bee colony algorithm and back propagation neural network. Journal of Manufacturing Systems. https://doi.org/10.1016/j.jmsy.2021.01.018.

Zhang, Z., Hua, B. S., Rosen, D. W., & Yeung, S. K. (2019). Rotation invariant convolutions for 3D point clouds deep learning International Conference on 3D Vision, Quebec, Canada.

Zhang, Z., Hua, B. S., Yeung, S. K. (2022). Riconv++: Effective rotation invariant convolutions for 3d point clouds deep learning. International Journal of Computer Vision, 130(5), 1228–1243.

Zhao, C., Dinar, M., & Melkote, S. N. (2020). Automated classification of manufacturing process capability utilizing part shape, material, and Quality attributes. Journal of Computing and Information Science in Engineering, 20(2), 021011. https://doi.org/10.1115/1.4045410

Zhao, C., Dinar, M., & Melkote, S. N. (2022). A data-driven framework for learning the capability of manufacturing process sequences. Journal of Manufacturing Systems, 64, 68–80. https://doi.org/10.1016/j.jmsy.2022.05.009.

Acknowledgements

The authors gratefully acknowledge support from the National Science Foundation, grants CMMI-2113672 and FMRG-2229260. Any opinions, findings, and conclusions or recommendations expressed in this publication are those of the authors and do not necessarily reflect the views of the National Science Foundation.

The code and dataset to this work can be found in https://github.com/ZhichaoWang970201/Similarity-Search.git.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Yan, X., Bjorni, J. et al. Manufacturing process selection based on similarity search: incorporating non-shape information in shape descriptor comparison. J Intell Manuf (2024). https://doi.org/10.1007/s10845-024-02368-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10845-024-02368-5