Abstract

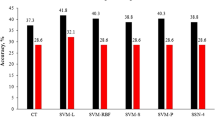

This study covers an application in predicting error parameters for logistic service sector (logistic service provider). In the application real data regarding the last 5 years of a 3PL company has been used. The most significant criterion of the success of 3PL companies is the storage and transference of their products to their customers with no damage. It is for this reason that the data related to errors, in particular, have been dwelled upon. Data mining and ANN techniques used in practice are in widespread use. However, examples of their application in providing logistic service are few in number. For this purpose, the classification techniques of data mining were applied to estimate 3PL damage parameters as the class attribute. Find laws, decision tree and decision forest modules (engines) of Polyanalyst are used to discover the similarities and information recovery about the 3PL damage parameters. Moreover, in this study, to compare the prediction results artificial neural networks are used. In order to catch robust and adaptive neural network approach, four types of neural predictors are operated in this research. These neural network predictors are; Back Propagation Neural Network (BBNN), General Regression Neural Network, Radial Basis Neural Network and Adaptive Neuro-Fuzzy Neural Network (ANFIS). The results of four structures have proven that an ANFIS type can be employed to estimate the damage parameters of a 3PL company. This study shows how the 3PL can evaluate and dataof damages to improve their service quality and cost effectiveness to the customers. he analysis of the data related operational errors in 3PL’s is one of the most important contributions of this study in that such analyses can guide this and other similar companies in managing and reducing the number of their future errors. Analysis of these damages with artificial intelligence may help prevent 3PLs for the future process and also predict the effect of cost for the company.

Similar content being viewed by others

References

Aguezzoul, A. (2014). Third-party logistics selection problem: A literature review on criteria and methods. Omega, 49, 69–78.

Aktas, E., & Ulengin, F. (2011). The use of outsourcing logistics activities: The case of Turkey. Transportation Research Part C: Emerging Technologies, 19(5), 833–852.

Caplice, C., & Sheff, Y. (1995). A review and evaluation of logistics performance measurement systems. The International Journal of Logistics Management, 6(1), 61–74.

Chen, T. A., & Hsu, T. C. (2006). A GAs based approach for mining breast cancer pattern. Expert Systems with Applications, 30, 674–681.

Choudhary, A. K., Harding, J. A., & Tiwari, M. K. (2009). Data mining in manufacturing: A review based on the kind of knowledge. The International Journal of Logistics Management,. doi:10.1007/s10845-008-0145-x.

Chun-Ming, W., & Qiang-Huan, S. (2016). Fault diagnosis of wind turbine vibration based on wavelet transform and neural network. Journal of Information Hiding and Multimedia Signal Processing, 7(4), 898–905.

Denizhan, B., & Konuk, A. (2013). Cases of damage in third-party logistics businesses Quality management of reverse Logistics; A broad look on quality issues and their interaction with closed loop supply chain, (pp. 131–154)

Dong, L., Wang, P., & Yan, F. (2016). Damage forecasting based on multi-factor fuzzy time series and cloud model. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-016-1264-4.

Editorial. (2006). Recent advances in data mining. Engineering Applications of Artificial Intelligence, 19, 361–362.

Erdemir, D., & Ayata, T. (2017). Prediction of temperature decreasing on a green roof by using artificial neural network. Applied Thermal Engineering, 112, 1317–1325.

Fayyad, U., Piatetsky-Shapiro, G., & Smyth, P. (1996). From data mining to knowledge discovery in databases. Artificial Intelligent Magazine, 17(3), 37.

Goebel, M., & Gruenwald, L. (1999). A survey of data mining and knowledge discovery software tools. ACM SIGKDD Explorations Newsletter Homepage archive, 1(1), 20–33.

Gürbüz, F., Özbakir, L., & Yapici, H. (2009). Classification rule discovery for the aviation incidents resulted in fatality. Knowledge-Based Systems, 22, 622–632.

Gürbüz, F., Özbakir, L., & Yapici, H. (2011). Data mining and preprocessing application on component reports of an airline company in Turkey. Expert Systems with Applications, 38, 6618–6626.

Hand, D., Manila, H., & Smyth, P. (2001). Principles of data mining. Cambridge, MA: MIT Press.

Hsia, T. C., Shie, A. J., & Chen, L. C. (2008). Course planning of extension education to meet market demand by using data mining techniques - an example of Chinkuo technology niversity in Taiwan. Expert Systems with Applications, 34, 596–602.

Jain, R., Singh, A. R., Yadav, H. C., & Mishra, P. K. (2014). Using data mining synergies for evaluating criteria at pre-qualification stage of supplier selection. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-012-0684-z.

Jazairy, A., Lenhardt, J., & von Haartman, R. (2017). Improving logistics performance in cross-border 3PL relationships. International Journal of Logistics Research and Applications A Leading Journal of Supply Chain Management,. doi:10.1080/13675567.2017.1306036.

Jiawei, H., & Kamber, M. (2001). Data mining: Concepts and techniques. Burnaby: University of Simon Fraser.

Kiselev, M. V., Ananyan, S. M., Arseniev, S. B. (1997). Regression-based classification methods and their comparison with decision tree algorithms. In: Komorowski J, Zytkow J. (eds) Principles of data mining and knowledge discovery. PKDD 1997. Lecture Notes in Computer Science (Lecture Notes in Artificial Intelligence), vol 1263. Springer, Berlin, Heidelberg

Kumar, S. K., Tiwari, M. K., & Babiceanu, R. F. (2010). Minimisation of supply chan cost with embedded risk using computational intelligence appoaches. International Journal of Production Research, 48(3), 3717.

Kuri-Morales, A., & Rodrıguez-Erazo, F. (2009). A search space reduction methodology for data mining in large databases. Engineering Applications of Artificial Intelligence, 22, 57–65.

Larose, D. T. (2005). Discovering knowledge in data: An Introduction to Data Mining. Director of data mining Central Connecticut State University. Wiley, Canada.

Neaga, I., Liu, S., Xu, L., Chen, H., & Hao, Y. (2015). Cloud Enabled Big Data Business Platform for Logistics Services: A Research and Development Agenda, International Conference on Decision Support System Technology ICDSST 2015: Decision Support Systems V – Big Data Analytics for Decision Making pp 22-33.

Qiao, B., Pan, S., & Ballot, E. (2016). Dynamic pricing model for less-than-truckload carriers in the Physical Internet. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-016-1289-8.

Rippa, S., & Lendyuk, T. (2007). Selection of Alternative Projects Using Data Mining, IEEE international workshop on intelligent data acquisition and advanced computing systems: Technology and applications. Germany: Dortmund.

Sahoo, A. K., Zuo, M. J., & Tiwari, M. K. (2012). A data clustering algorithm for stratified data partitioning in artificial neural network. Expert Systems with Applications, 39, 7004–7014.

Schikora, P. F., & Godfrey, M. R. (2003). Efficacy of end-user neural network and data mining software for predicting complex system performance. International Journal Production Economics, 84, 231–253.

Simchi-Levi, D., (MIT), & Kaminsky, P. (2003–2007). Designing & Managing the Supply Chain, 3rd Edition, McGraw-Hill, ISBN: 0-07-284553-8.

Strik, D. P. B. T. B., Domnanovich, A. M., Zani, L., Braun, R., & Holubar, P. (2005). Prediction of trace compounds in biogas from anaerobic digestion using the MATLAB Neural Network Toolbox. Environmental Modelling & Software, 20, 803–810.

Ulmer D, (2002). Mining an Online Auctions Data Warehouse, Proceedings of MASPLAS’02, The Mid-Atlantic Student Workshop on Programming Languages and Systems, Pace University.

User Manuel of PolyAnalyst 5, April 2005.

Xiong, G, Nyberg, T. R., Dong, X., & Shang, X. (2015). Intelligent Technologies and Systems of Material Management, Chapter Intelligent Techniques in Engineering Management, Volume 87 of the series Intelligent Systems Reference Library, (pp. 295–330).

Yang, G., & Liu, Y. (2015). Designing fuzzy supply chain network problem by mean-risk optimization method. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-013-0801-7.

Yeung, A. C. L. (2006). The impact of third-party logistics performance on the logistics and export performance of users: anempirical study. Maritime Economics and Logistics, 8(2), 121–39.

Yıldırım, Ş., Eski, İ., & Polat, Y. (2013). Design of adaptive neural predictor for failure analysis on hip and knee joints of humans. Neural computıng & Applications, 23(1), 73–87.

Ying, W., & Dayong, S. (2005). Multi-agent framework for third party logistics in E-commerce. Expert Systems with Applications, 29, 431–436.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gürbüz, F., Eski, İ., Denizhan, B. et al. Prediction of damage parameters of a 3PL company via data mining and neural networks. J Intell Manuf 30, 1437–1449 (2019). https://doi.org/10.1007/s10845-017-1337-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-017-1337-z