Abstract

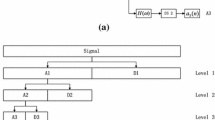

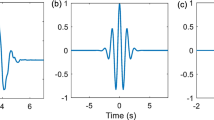

This paper proposes a supervised sparsity-based wavelet feature (SSWF) for the detection of bearing fault, which combines wavelet packet transform (WPT) and sparse coding. SSWF is extracted from vibration signals by four main steps: (1) construct a WPT vector using the fault-related WPT coefficients; (2) design a structured dictionary that combines the signal characteristics and class information; (3) use the dictionary to implement the sparse coding of the WPT vectors, which can be solved by basis pursuit (BP) and (4) calculate the SSWF from the sparse coefficients. During the process, WPT can detect the fault occurrence of the bearing signal. Sparse coding based on a structured dictionary can find a robust representation of the signal and at the same time, integrate the class information. Therefore, SSWF is able to stably and discriminatively reflect different fault types, which indicates its potential in bearing fault diagnosis. Experiments on two bearing cases are conducted to verify the advantages of SSWF in the detection of bearing faults.

Similar content being viewed by others

References

Afonso, M. V., Bioucas-Dias, J. M., & Figueiredo, M. A. T. (2010). Fast image recovery using variable splitting and constrained optimization. IEEE Transactions on Image Processing, 19(9), 2345–2356.

Aharon, M., Elad, M., & Bruckstein, A. (2006). K-svd: An algorithm for designing overcomplete dictionaries for sparse representation. IEEE Transactions on Signal Processing, 54(11), 4311–4322.

Amaldi, E., & Kann, V. (1998). On the approximability of minimizing nonzero variables or unsatisfied relations in linear systems. Theoretical Computer Science, 209(1–2), 237–260.

Aydin, I., Karakose, M., & Akin, E. (2015). Combined intelligent methods based on wireless sensor networks for condition monitoring and fault diagnosis. Journal of Intelligent Manufacturing, 26(4), 717–729.

Beck, A., & Teboulle, M. (2009). A fast iterative shrinkage-thresholding algorithm for linear inverse problems. SIAM Journal on Imaging Sciences, 2(1), 183–202.

Bokoski, P., & Juricic, D. (2012). Fault detection of mechanical drives under variable operating conditions based on wavelet packet Renyi entropy signatures. Mechanical Systems and Signal Processing, 31, 369–381.

Chandra, N. H., & Sekhar, A. S. (2016). Fault detection in rotor bearing systems using time frequency techniques. Mechanical Systems and Signal Processing, 72–73, 105–133.

Chen, S. S. B., Donoho, D. L., & Saunders, M. A. (2001). Atomic decomposition by basis pursuit. Siam Review, 43(1), 129–159.

Coifman, R. R., & Wickerhauser, M. V. (1992). Entropy-based algorithms for best basis selection. IEEE Transactions on Information Theory, 38(2), 713–718.

Ding, X. X., He, Q. B., & Luo, N. W. (2015). A fusion feature and its improvement based on locality preserving projections for rolling element bearing fault classification. Journal of Sound and Vibration, 335, 367–383.

Figueiredo, M. A. T., Nowak, R. D., & Wright, S. J. (2007). Gradient projection for sparse reconstruction: Application to compressed sensing and other inverse problems. IEEE Journal of Selected Topics in Signal Processing, 1(4), 586–597.

Gao, R. X., & Yan, R. (2006). Non-stationary signal processing for bearing health monitoring. International Journal of Manufacturing Research, 1(1), 18–40.

Gunn, R. N., Gunn, S. R., Turkheimer, F. E., Aston, J. A. D., & Cunningham, T. J. (2002). Positron emission tomography compartmental models: A basis pursuit strategy for kinetic modeling. Journal of Cerebral Blood Flow and Metabolism, 22(12), 1425–1439.

He, W. P., Ding, Y., Zi, Y. Y., & Selesnick, I. W. (2016). Sparsity-based algorithm for detecting faults in rotating machines. Mechanical Systems and Signal Processing, 72–73, 46–64.

Kim, S. J., Koh, K., Lustig, M., Boyd, S., & Gorinevsky, D. (2007). An interior-point method for large-scale l(1)-regularized least squares. IEEE Journal of Selected Topics in Signal Processing, 1(4), 606–617.

Lei, Y. G., He, Z. J., & Zi, Y. Y. (2008). A new approach to intelligent fault diagnosis of rotating machinery. Expert Systems with Applications, 35(4), 1593–1600.

Li, F. C., Meng, G., Ye, L., & Chen, P. (2008). Wavelet transform-based higher-order statistics for fault diagnosis in rolling element bearings. Journal of Vibration and Control, 14(11), 1691–1709.

Li, H. K., Lian, X. T., Guo, C., & Zhao, P. S. (2015). Investigation on early fault classification for rolling element bearing based on the optimal frequency band determination. Journal of Intelligent Manufacturing, 26(1), 189–198.

Li, H. K., Wang, Y. H., Zhao, P. S., Zhang, X. W., & Zhou, P. L. (2015). Cutting tool operational reliability prediction based on acoustic emission and logistic regression model. Journal of Intelligent Manufacturing, 26(5), 923–931.

Mallat, S. G., & Zhang, Z. (1993). Matching pursuits with time-frequency dictionaries. IEEE Transactions on Signal Processing, 41, 3397–3415.

Mallat, S. G. (1989). A theory for multiresolution signal decomposition—the wavelet representation. IEEE Transactions on Pattern Analysis and Machine Intelligence, 11(7), 674–693.

Mateos, G., Bazerque, J. A., & Giannakis, G. B. (2010). Distributed sparse linear regression. IEEE Transactions on Signal Processing, 58(10), 5262–5276.

Missoum, S., Vergez, C., & Doc, J. B. (2014). Explicit mapping of acoustic regimes for wind instruments. Journal of Sound and Vibration, 333(20), 5018–5029.

Mortada, M. A., Yacout, S., & Lakis, A. (2014). Fault diagnosis in power transformers using multi-class logical analysis of data. Journal of Intelligent Manufacturing, 25(6), 1429–1439.

Onan, A. (2016). Classifier and feature set ensembles for web page classification. Journal of Information Science, 42(2), 150–165.

Pavlidi, D., Griffin, A., Puigt, M., & Mouchtaris, A. (2013). Real-time multiple sound source localization and counting using a circular microphone array. IEEE Transactions on Audio Speech and Language Processing, 21(10), 2193–2206.

Rahmani, H., Huynh, D. Q., Mahmood, A., & Mian, A. (2016). Discriminative human action classification using locality-constrained linear coding. Pattern Recognition Letters, 72, 62–71.

Shukla, N., Ceglarek, D., & Tiwari, M. K. (2015). Key characteristics-based sensor distribution in multi-station assembly processes. Journal of Intelligent Manufacturing, 26(1), 43–58.

Siracusano, G., Lamonaca, F., Tomasello, R., Garesci, F., La Corte, A., Carni, D. L., et al. (2016). A framework for the damage evaluation of acoustic emission signals through Hilbert–Huang transform. Mechanical Systems and Signal Processing, 75, 109–122.

Sui, Y., Zhang, S. L., & Zhang, L. (2015). Robust visual tracking via sparsity-induced subspace learning. IEEE Transactions on Image Processing, 24(12), 4686–4700.

Wang, G. F., & Cui, Y. H. (2013). On line tool wear monitoring based on auto associative neural network. Journal of Intelligent Manufacturing, 24(6), 1085–1094.

Wilcoxon, F. (1945). Individual comparisons by ranking methods. Biometrics Bulletin, 1(6), 80–83.

Wright, J., Yang, A. Y., Ganesh, A., Sastry, S. S., & Ma, Y. (2009). Robust face recognition via sparse representation. IEEE Transactions on Pattern Analysis and Machine Intelligence, 31(2), 210–227.

Yan, R. Q., Gao, R. X., & Chen, X. F. (2014). Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Processing, 96, 1–15.

Yeganli, F., Nazzal, M., & Ozkaramanli, H. (2015). Image super-resolution via sparse representation over multiple learned dictionaries based on edge sharpness and gradient phase angle. Signal Image and Video Processing, 9, 285–293.

Zarei, J., & Poshtan, J. (2007). Bearing fault detection using wavelet packet transform of induction motor stator current. Tribology International, 40(5), 763–769.

Zhang, H., Chen, X. F., Du, Z. H., Li, X., & Yan, R. Q. (2016). Nonlocal sparse model with adaptive structural clustering for feature extraction of aero-engine bearings. Journal of Sound and Vibration, 368, 223–248.

Zhang, Z. Y., Wang, Y., & Wang, K. S. (2013). Fault diagnosis and prognosis using wavelet packet decomposition, fourier transform and artificial neural network. Journal of Intelligent Manufacturing, 24(6), 1213–1227.

Acknowledgments

This work was supported by the National Key Basic Research Program of China (973 Program) under Grant No. 2014CB049500 and the Key Technologies R&D Program of Anhui Province under Grant No. 1301021005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Gan, M. & Zhu, C. A supervised sparsity-based wavelet feature for bearing fault diagnosis. J Intell Manuf 30, 229–239 (2019). https://doi.org/10.1007/s10845-016-1243-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-016-1243-9