Abstract

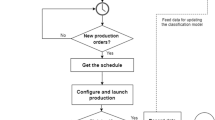

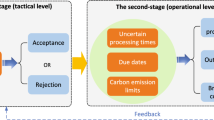

In actual manufacturing processes, some unexpected disturbances, called as recessive disturbances (e.g., job set-up time variation and arrival time deviation), would gradually make the original production schedule obsolete. It is hard for production managers to perceive their presences. Thus, the impact of recessive disturbances can not be eliminated by rescheduling in time. On account of this, a rescheduling decision mechanism for recessive disturbances in RFID-driven job shops is proposed in this article, and a manifold learning method, which reduces the response time of manufacturing system, is applied in the mechanism to preprocess manufacturing data. The rescheduling decision mechanism is expected to answer the questions of whether to reschedule, when to reschedule, and which rescheduling method to be used. Firstly, RFID devices acquire the actual process completion time of all work in process (WIPs) at every WIP machining process completion time. Secondly, recessive disturbances are quantified to time accumulation error (TAE) which represents the difference between actual process completion time and planned process completion time. Lastly, according to the TAE and production managers’ experience, the rescheduling decision mechanism selects a proper rescheduling method to update or repair the original production schedule. The realization algorithms of rescheduling decision mechanism includes: (1) supervised locally linear embedding. (2) General regression neural network. (3) Least square-support vector Machine. Finally, a numerical experiment is used to demonstrate the implementation procedures of the rescheduling decision mechanism.

Similar content being viewed by others

References

Abumaizar, R. J., & Svestka, J. A. (1997). Rescheduling job shops under random disruptions. International Journal of Production Research, 35(7), 2065–2082.

Ahmed, E., & Lee, C. S. (2004). Inferring 3D body pose from silhouettes using activity manifold learning. In Paper Presented at the 2013 IEEE Conference on Computer Vision and Pattern Recognition.

Akturk, M. S., & Gorgulu, E. (1999). Match-up scheduling under a machine breakdown. European Journal of Operational Research, 112(1), 81–97.

Brewer, A., Sloan, N., & Landers, T. L. (1999). Intelligent tracking in manufacturing. Journal of Intelligent Manufacturing, 10(3), 245–250.

Cristianini, N., & John, S. (2000). An introduction to support vector machines and other kernel-based learning methods. Cambridge: Cambridge University Press.

Dong, Y., & Jang, J. (2011). Production rescheduling for machine breakdown at a job shop. International Journal of Production Research, 50(5), 2681–2691.

Editor (Ed.). (2013). Recommendations for implementing the strategic initiative INDUSTRIE 4.0: Securing the future of German manufacturing industry. In Final Report of the Industrie 4.0 Working Group, Forschungsunion.

Fattahi, P., & Fallahi, A. (2010). Dynamic scheduling in flexible job shop systems by considering simultaneously efficiency and stability. CIRP Journal of Manufacturing Science and Technology, 2(2), 114–123.

Herroelen, W., & Roel, L. (2005). Project scheduling under uncertainty: Survey and research potentials. European Journal of Operational Research, 165(2), 289–306.

Huang, G. Q., Zhang, Y. F., & Jiang, P. Y. (2007). RFID-based wireless manufacturing for walking-worker assembly islands with fixed-position layouts. Robotics and Computer-Integrated Manufacturing, 23(4), 469–477. doi:10.1016/j.rcim.2006.05.006.

Jiang, P., & Cao, W. (2013). An RFID-driven graphical formalized deduction for describing the time-sensitive state and position changes of work-in-progress material flows in a job-shop floor. Journal of Manufacturing Science and Engineering, 135(3), 189–197.

Jiang, Q., Jia, M., Hu, J., & Feiyun, X. (2009). Machinery fault diagnosis using supervised manifold learning. Mechanical Systems and Signal Processing, 23(1), 2301–2311.

Katragjini, K., Vallada, E., & Ruiz, R. (2013). Flow shop rescheduling under different types of disruption. International Journal of Production Research, 51(3), 780–797.

Kouropteva, O., Okun, O., Ainen, M. P. (2003). Supervised Locally Linear Embedding Algorithm for Pattern Recognition. Paper presented at the IbPRIA,. (2003). Puerto de Andratx. Spain: Mallorca.

Li, B., & Zhang, Y. (2011). Supervised locally linear embedding projection (SLLEP) for machinery fault diagnosis. Mechanical Systemsand Signal Processing, 25(8), 3125–3134.

Li, R. K. (1995). A new rescheduling method for computer based scheduling systems. International Journal of Production Research, 33(8), 2097–2110.

Lin, F., Yeh, C., & Lee, M. (2011). The use of hybrid manifold learning and support vector machines in the prediction of business failure. Knowledge-Based Systems, 24(1), 95–101.

Liu, M., Shan, H., Jiang, Z., Ge, M., Hu, J., & Zhang, M. (2009). Dynamic rescheduling optimization of job-shop under uncertain conditions. Journal of Mechanical Engineering, 45(10), 137–142.

Liu, M., Zhang, X., Zhang, M., Ge, M., & Hu, J. (2014). Rescheduling decision method of manufacturing shop based on profit-loss cloud model. Control and Decision, 29(8), 1458–1464.

Lv, S., & Qiao, L. (2014). Process planning and scheduling integration with optimal rescheduling strategies. International Journal of Computer Integrated Manufacturing, 27(7), 638–655.

Malte, B., Niklas, F., Michael, K., & Marius, R. (2014). How virtualization, decentralization and network building change the manufacturing landscape: An Industry 4.0 Perspective. International Journal of Science. Engineering and Technology, 8(1), 37–44.

Martin, H. C. L., & Anil, K. J. (2006). Incremental nonlinear dimensionality reduction by manifold learning. IEEE Transactions on Pattern Analysis and Machine Intelligence, 28(3), 377–391.

Mehrjerdi, Y. Z. (2008). RFID-enabled systems: A brief review. Assembly Automation, 28(3), 235–245.

Mohsen, S., Razieh, S., & Ziari, M. B. (2010). QSAR study of anthranilic acid sulfonamides as inhibitors of methionine aminopeptidase-2 using LS-SVM and GRNN based on principal components. European Journal of Medicinal Chemistry, 45(10), 4499–4508.

Neal, P., & Alfred, O. H. I. (2004). Manifold learning algorithms for localization in wireless sensor networks. In Paper presented at the 2004 IEEE International Conference on Acoustics, Speech, and Signal Processing.

Olumolade, M. O. (1996). Reactive scheduling system for cellular manufacturing with failure-prone machines. International Journal of Computer Integrated Manufacturing, 9(2), 131–144. doi:10.1080/095119296131742.

Ovacik, I. M., & Uzsoy, R. (1997). Decomposition methods for complex factory scheduling problems. Berlin: Springer.

Pratap, S., Daultani, Y., Tiwari, M. K., & Mahanty, B. (2015). Rule based optimization for a bulk material handling port operation. Journal of Intelligent Manufacturing. doi:10.1007/s10845-015-1108-7.

Qiao, F., Wu, Q., Li, L., Wang, Z., & Shi, B. (2011). A fuzzy Petri net-based reasoning method for rescheduling. Transactions of the Institute of Measurement and Control, 33(3), 435–455. doi:10.1177/0142331208100100.

Roweis, S. T., & Saul, L. K. (2000). Nonlinear dimensionality reduction by locally linear embedding. Science, 290(22), 2323–2326.

Sabuncuoglu, & Bayız, M. (2000). Analysis of reactive scheduling problems in a job shop environment. European Journal of Operational Research, 126(3), 567–586.

Saul, L. K., & Roweis, S. (2003). Think globally, fit locally: Unsupervised learning of low dimensional manifolds. The Journal of Machine Learning Research, 4(12), 119–155.

Suwa, H. (2007). A new when-to-schedule policy in online scheduling based on cumulative task delays. International Journal of Production Economics, 110(1), 175–186. doi:10.1016/j.ijpe.2007.02.015.

Tenenbaum, J. B., de Silva, V., & Langford, J. C. (2000). A global geometric framework for nonlinear dimensionality reduction. Science, 290(22), 2319–2323.

Vieira, G. E., Herrmann, J. W., & Lin, E. (2003). Rescheduling manufacturing systems: A framework of strategies, policies, and methods. Journal of Scheduling, 6(1), 39–62.

Vieira, G. E., Herrmann, W. J., & Lin, E. (2000). Predicting the performance of rescheduling strategies for parallel machine systems. Journal of Manufacturing Systems, 19(4), 256–266.

Wang, S., Xi, L., & Zhou, B. (2008). FBS-enhanced agent-based dynamic scheduling in FMS. Engineering Applications of Artificial Intelligence, 21(4), 644–657.

Zhong, R. Y., Li, Z., Pang, L. Y., Pan, Y., Qu, T., & Huang, G. Q. (2013). RFID-enabled real-time advanced planning and scheduling shell for production decision making. International Journal of Computer Integrated Manufacturing, 26(7), 649–662. doi:10.1080/0951192X.2012.749532.

Zhou, G., Zheng, M., & Xiao, Z. (2011). Dynamic job rescheduling using RFID technology. Internet Manufacturing and Services, 3(1), 42–58.

Acknowledgments

The research work presented in this paper is under the support of National Natural Science Foundation of China with Grant No. 51275396 and National Basic Research Program of China with Grant No. 2011CB706805.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Jiang, P. Manifold learning based rescheduling decision mechanism for recessive disturbances in RFID-driven job shops. J Intell Manuf 29, 1485–1500 (2018). https://doi.org/10.1007/s10845-016-1194-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-016-1194-1