Abstract

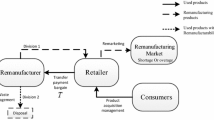

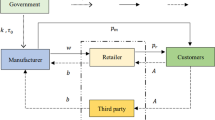

In this paper, a modal interval based method is proposed to characterize the uncertainty in the quality of collected used products for a closed-loop supply chain. Triggered by an actual case in the construction machinery remanufacturing field, we establish a decent model of a remanufacturer-driven closed-loop supply chain with multi-dimensional reverse channel within the framework of game theory, which includes the supplier, the manufacturer, the retailer with authorization to remanufacture, and the third party collector. In this special remanufacturer-driven supply chain, both the retailer and the third party collector collect the used products for the remanufacturer. Considering the influence of uncertainty in the quality of used products on the buyback price and the cost of remanufacturing process, we utilize modal interval arithmetic to analyze the dynamic pricing and collection strategy of the remanufacturer. Moreover, to validate the effectiveness of the proposed modal interval based method, we compare it with the analysis under the traditional scenario based method. We confirm that the modal interval method can obtain more robust results, and the proposed model and method of our research can give guidance to the construction machinery remanufacturing firms when facing with the quality uncertainty of the collected used products in remanufacturing activities.

Similar content being viewed by others

References

Chen, J.-M., & Chang, C.-I. (2013). Dynamic pricing for new and remanufactured products in a closed-loop supply chain. International Journal of Production Economics, 146(1), 153–160. doi:10.1016/j.ijpe.2013.06.017.

Das, D., & Dutta, P. (2013). A system dynamics framework for integrated reverse supply chain with three way recovery and product exchange policy. Computers and Industrial Engineering, 66(4), 720–733. doi:10.1016/j.cie.2013.09.016.

Easwaran, G., & Üster, H. (2010). A closed-loop supply chain network design problem with integrated forward and reverse channel decisions. IIE Transactions, 42(11), 779–792. doi:10.1080/0740817X.2010.504689.

Ferguson, M. E., Guide, V. D., Koca, E., & Van Souza, G. C. (2009). The value of quality grading in remanufacturing. Production and Operations Management, 18(3), 300–314. doi:10.1111/j.1937-5956.2009.01033.x.

Ferguson, M. E., & Toktay, L. B. (2006). The effect of competition on recovery strategies. Production and Operations Management, 15(3), 351.

Gardeñes, E., Sainz, M., Jorba, L., Calm, R., Estela, R., Mielgo, H., et al. (2001). Modal intervals. Reliable Computing, 7(2), 77–111. doi:10.1023/A:1011465930178.

Giutini, R., & Gaudette, K. (2003). Remanufacturing: The next great opportunity for boosting US productivity. Business Horizons, 46(6), 41–48. doi:10.1016/S0007-6813(03)00087-9.

Guide, V. D. R., & Wassenhove, L. N. (2006). Closed-loop supply chains: An introduction to the feature issue (part 1). Production and Operations Management, 15(3), 345–350. doi:10.1111/j.1937-5956.2006.tb00249.x.

Guide, V. D. R., & Wassenhove, L. N. (2009). Managing product returns for remanufacturing. Production and Operations Management, 10(2), 142–155. doi:10.1111/j.1937-5956.2001.tb00075.x.

Gutowski, T., Murphy, C., Allen, D., Bauer, D., Bras, B., Piwonka, T., et al. (2005). Environmentally benign manufacturing: Observations from Japan, Europe and the United States. Journal of Cleaner Production, 13(1), 1–17. doi:10.1016/j.jclepro.2003.10.004.

Hong, X., Wang, Z., Wang, D., & Zhang, H. (2013). Decision models of closed-loop supply chain with remanufacturing under hybrid dual-channel collection. The International Journal of Advanced Manufacturing Technology, 68(5–8), 1851–1865. doi:10.1007/s00170-013-4982-1.

Huang, M., Song, M., Lee, L. H., & Ching, W. K. (2013). Analysis for strategy of closed-loop supply chain with dual recycling channel. International Journal of Production Economics, 144(2), 510–520. doi:10.1016/j.ijpe.2013.04.002.

Jung, K., & Hwang, H. (2011). Competition and cooperation in a remanufacturing system with take-back requirement. Journal of Intelligent Manufacturing, 22(3), 427–433. doi:10.1007/s10845-009-0300-z.

Karakayali, I., Emir-Farinas, H., & Akcali, E. (2007). An analysis of decentralized collection and processing of end-of-life products. Journal of Operations Management, 25(6), 1161–1183. doi:10.1016/j.jom.2007.01.017.

Kaucher, E. (1980). Interval analysis in the extended interval space IR. In G. Alefeld & R. Grigorieff (Eds.), Fundamentals of numerical computation (computer-oriented numerical analysis) SE-3 (pp. 33–49). Vienna: Springer. doi:10.1007/978-3-7091-8577-3_3.

Kumar, V. V., & Chan, F. T. S. (2011). A superiority search and optimisation algorithm to solve RFID and an environmental factor embedded closed loop logistics model. International Journal of Production Research, 49(16), 4807–4831. doi:10.1080/00207543.2010.503201.

Kumar, V. V., Chan, F. T. S., Mishra, N., & Kumar, V. (2010). Environmental integrated closed loop logistics model: An artificial bee colony approach. In Supply chain management and information systems (SCMIS), 2010 8th international conference on.

Kumar, V. V., Liou, F. W., Balakrishnan, S. N., & Kumar, V. (2013). Economical impact of RFID implementation in remanufacturing: A chaos-based interactive artificial bee colony approach. Journal of Intelligent Manufacturing. doi:10.1007/s10845-013-0836-9.

Naeem, M. A., Dias, D. J., Tibrewal, R., Chang, P. C., & Tiwari, M. K. (2012). Production planning optimization for manufacturing and remanufacturing system in stochastic environment. Journal of Intelligent Manufacturing, 24(4), 717–728. doi:10.1007/s10845-011-0619-0.

Östlin, J., Sundin, E., & Björkman, M. (2008). Importance of closed-loop supply chain relationships for product remanufacturing. International Journal of Production Economics, 115(2), 336–348. doi:10.1016/j.ijpe.2008.02.020.

Rao, S. S., & Berke, L. (1997). Analysis of uncertain structural systems using interval analysis. AIAA Journal, 35, 727–735. doi:10.2514/2.164.

Savaskan, R. C., Bhattacharya, S., & Van Wassenhove, L. N. (2004). Closed-loop supply chain models with product remanufacturing. Management Science, 50(2), 239–252. doi:10.1287/mnsc.1030.0186.

Schultmann, F., Zumkeller, M., & Rentz, O. (2006). Modeling reverse logistic tasks within closed-loop supply chains: An example from the automotive industry. European Journal of Operational Research, 171(3), 1033–1050. doi:10.1016/j.ejor.2005.01.016.

Shevtshenko, E., & Wang, Y. (2009). Decision support under uncertainties based on robust Bayesian networks in reverse logistics management. International Journal of Computer Applications in Technology, 36(3–4), 247–258. doi:10.1504/IJCAT.2009.028047.

Shi, Y., Nie, J., Qu, T., Chu, L. K., & Sculli, D. (2015). Choosing reverse channels under collection responsibility sharing in a closed-loop supply chain with re-manufacturing. Journal of Intelligent Manufacturing, 26(2), 387–402. doi:10.1007/s10845-013-0797-z.

Steinhilper, R. (1998). Remanufacturing: The ultimate form of recycling. Fraunhofer-IRB-Verlag Stuttgart.

Teunter, R. H., & Flapper, S. D. P. (2011). Optimal core acquisition and remanufacturing policies under uncertain core quality fractions. European Journal of Operational Research, 210(2), 241–248. doi:10.1016/j.ejor.2010.06.015.

Wang, Y. (2010). Imprecise probabilities based on generalised intervals for system reliability assessment. International Journal of Reliability and Safety, 4(4), 319–342. doi:10.1504/IJRS.2010.035572.

Wei, J., & Zhao, J. (2013). Reverse channel decisions for a fuzzy closed-loop supply chain. Applied Mathematical Modelling, 37(3), 1502–1513. doi:10.1016/j.apm.2012.04.003.

Xie, F., Wu, B., Hu, Y., Wang, Y., Jia, G., & Cheng, Y. (2014). A generalized interval probability-based optimization method for training generalized hidden Markov model. Signal Processing, 94(1), 319–329. doi:10.1016/j.sigpro.2013.06.009.

Xu, J., & Liu, N. (2014). Research on closed loop supply chain with reference price effect. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-014-0961-0.

Acknowledgments

This research is supported by the National High Technology Research and Development Program of P.R. China under Grant No. 2013AA040206. The authors sincerely thank the editors and the anonymous reviewers for their kind comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, M., Yi, P., Shi, T. et al. A modal interval based method for dynamic decision model considering uncertain quality of used products in remanufacturing. J Intell Manuf 29, 925–935 (2018). https://doi.org/10.1007/s10845-015-1151-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1151-4