Abstract

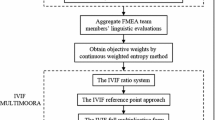

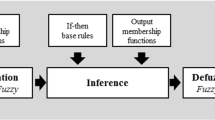

Failure mode and effects analysis (FMEA) is a widely used engineering technique for identifying and eliminating known and potential failures from systems, designs, products, processes or services. However, the conventional risk priority number method has been extensively criticized in the literature for a lot of reasons such as ignoring relative importance of risk factors, questionable multiplication procedure, and imprecisely evaluation. In this article, a new FMEA model based on fuzzy digraph and matrix approach is developed to solve the problems and improve the effectiveness of the traditional FMEA. All the information about risk factors like occurrence (O), severity (S) and detection (D) and their relative weights are expressed in linguistic terms, represented by fuzzy numbers. By considering the risk factors and their relative importance, a risk factors fuzzy digraph is developed for the optimum representation of interrelations. Then, corresponding fuzzy risk matrixes are formed for all the identified failure modes in FMEA and risk priority indexes are computed for determining the risk priorities of the failure modes. Finally, a case study of steam valve system is included to illustrate the proposed fuzzy FMEA and the advantages are highlighted by comparing with the listed methods.

Similar content being viewed by others

References

Akman, G., Özcan, B., & Hatipoğlu, T. (2013). Fuzzy multi criteria decision making approach to innovative strategies based on Miles and Snow typology. Journal of Intelligent Manufacturing (in Press).

Ayağ, Z., & Özdemir, R. G. (2006). A fuzzy AHP approach to evaluating machine tool alternatives. Journal of Intelligent Manufacturing, 17(2), 179–190.

Ayağ, Z., Samanlioglu, F., & Büyüközkan, G. (2013). A fuzzy QFD approach to determine supply chain management strategies in the dairy industry. Journal of Intelligent Manufacturing, 24(6), 1111–1122.

Baykasoglu, A. (2012). A review and analysis of “graph theoretical-matrix permanent” approach to decision making with example applications. Artificial Intelligence Review, 1–33.

Baykasoğlu, A. (2009). A practical fuzzy digraph model for modeling manufacturing flexibility. Cybernetics and Systems: An International Journal, 40(6), 475–489.

Bowles, J. B., & Peláez, C. E. (1995). Fuzzy logic prioritization of failures in a system failure mode, effects and criticality analysis. Reliability Engineering and System Safety, 50(2), 203–213.

Chang, D. S., Chung, J. H., Sun, K. L. P., & Yang, F. C. (2012). A novel approach for evaluating the risk of health care failure modes. Journal of Medical Systems, 36(6), 3967–3974.

Chang, K. H., Chang, Y. C., & Lai, P. T. (2013). Applying the concept of exponential approach to enhance the assessment capability of FMEA. Journal of Intelligent Manufacturing, 1–15 (in Press).

Chang, K. H., & Cheng, C. H. (2011). Evaluating the risk of failure using the fuzzy OWA and DEMATEL method. Journal of Intelligent Manufacturing, 22(2), 113–129.

Chen, C. T. (2000). Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets and Systems, 114(1), 1–9.

Chin, K. S., Chan, A., & Yang, J. B. (2008). Development of a fuzzy FMEA based product design system. The International Journal of Advanced Manufacturing Technology, 36(7), 633–649.

Chin, K. S., Wang, Y. M., Poon, G. K. K., & Yang, J. B. (2009). Failure mode and effects analysis using a group-based evidential reasoning approach. Computers and Operations Research, 36(6), 1768–1779.

Chou, C. (2003). The canonical representation of multiplication operation on triangular fuzzy numbers. Computers and Mathematics with Applications, 45(10), 1601–1610.

Darvish, M., Yasaei, M., & Saeedi, A. (2009). Application of the graph theory and matrix methods to contractor ranking. International Journal of Project Management, 27(6), 610–619.

Gandhi, O. P., & Agrawal, V. P. (1992). FMEA—A diagraph and matrix approach. Reliability Engineering and System Safety, 35(2), 147–158.

Garcia, P. A. A., Schirru, R., & Frutuoso Emelo, P. F. (2005). A fuzzy data envelopment analysis approach for FMEA. Progress in Nuclear Energy, 46(3–4), 359–373.

Gargama, H., & Chaturvedi, S. K. (2011). Criticality assessment models for failure mode effects and criticality analysis using fuzzy logic. IEEE Transactions on Reliability, 60(1), 102–110.

Jong, C. H., Tay, K. M., & Lim, C. P. (2013). Application of the fuzzy failure mode and effect analysis methodology to edible bird nest processing. Computers and Electronics in Agriculture, 96, 90–108.

Kahraman, C., Kaya, İ., & Şenvar, Ö. (2013). Healthcare failure mode and effects analysis under fuzziness. Human and Ecological Risk Assessment: An International Journal, 19(2), 538–552.

Koulouriotis, D. E., & Ketipi, M. K. (2011). A fuzzy digraph method for robot evaluation and selection. Expert Systems with Applications, 38(9), 11901–11910.

Kutlu, A. C., & Ekmekçioğlu, M. (2012). Fuzzy failure modes and effects analysis by using fuzzy TOPSIS-based fuzzy AHP. Expert Systems with Applications, 39(1), 61–67.

Kwong, C. K., & Bai, H. (2002). A fuzzy AHP approach to the determination of importance weights of customer requirements in quality function deployment. Journal of Intelligent Manufacturing, 13(5), 367–377.

Lin, Q. L., Liu, H. C., Wang, D. J., & Liu, L. (2013). Integrating systematic layout planning with fuzzy constraint theory to design and optimize the facility layout for operating theatre in hospitals. Journal of Intelligent Manufacturing (in Press).

Liu, H. C., Liu, L., Bian, Q. H., Lin, Q. L., Dong, N., & Xu, P. C. (2011). Failure mode and effects analysis using fuzzy evidential reasoning approach and grey theory. Expert Systems with Applications, 38(4), 4403–4415.

Liu, H. C., Liu, L., & Li, P. (2013a). Failure mode and effects analysis using intuitionistic fuzzy hybrid weighted Euclidean distance operator. International Journal of Systems Science (in Press).

Liu, H. C., Liu, L., & Lin, Q. L. (2013b). Fuzzy failure mode and effects analysis using fuzzy evidential reasoning and belief rule-based methodology. IEEE Transactions on Reliability, 62(1), 23–36.

Liu, H. C., Liu, L., & Liu, N. (2013c). Risk evaluation approaches in failure mode and effects analysis: A literature review. Expert Systems with Applications, 40(2), 828–838.

Liu, H. C., Liu, L., Liu, N., & Mao, L. X. (2012). Risk evaluation in failure mode and effects analysis with extended VIKOR method under fuzzy environment. Expert Systems with Applications, 39(17), 12926–12934.

Paramasivam, V., Senthil, V., & Rajam Ramasamy, N. (2011). Decision making in equipment selection: An integrated approach with digraph and matrix approach, AHP and ANP. The International Journal of Advanced Manufacturing Technology, 54(9–12), 1233–1244.

Pillay, A., & Wang, J. (2003). Modified failure mode and effects analysis using approximate reasoning. Reliability Engineering and System Safety, 79(1), 69–85.

Rao, R. V. (2006). A decision-making framework model for evaluating flexible manufacturing systems using digraph and matrix methods. The International Journal of Advanced Manufacturing Technology, 30(11–12), 1101–1110.

Rao, R. V., & Gandhi, O. P. (2002a). Digraph and matrix methods for the machinability evaluation of work materials. International Journal of Machine Tools and Manufacture, 42(3), 321–330.

Rao, R. V., & Gandhi, O. P. (2002b). Failure cause analysis of machine tools using digraph and matrix methods. International Journal of Machine Tools and Manufacture, 42(4), 521–528.

Rao, R. V., & Padmanabhan, K. K. (2006). Selection, identification and comparison of industrial robots using digraph and matrix methods. Robotics and Computer-Integrated Manufacturing, 22(4), 373–383.

Rao, R. V., & Padmanabhan, K. K. (2007). Rapid prototyping process selection using graph theory and matrix approach. Journal of Materials Processing Technology, 194(1), 81–88.

Sharma, R. K., Kumar, D., & Kumar, P. (2005). Systematic failure mode effect analysis (FMEA) using fuzzy linguistic modelling. International Journal of Quality and Reliability Management, 22(9), 986–1004.

Song, W., Ming, X., Wu, Z., & Zhu, B. (2013). A rough TOPSIS approach for failure mode and effects analysis in uncertain environments. Quality and Reliability Engineering International (in Press).

Stamatis, D. H. (2003). Failure mode and effect analysis: FMEA from theory to execution. New York: ASQC Press.

Vinodh, S., Aravindraj, S., Narayanan, R. S., & Yogeshwaran, N. (2012). Fuzzy assessment of FMEA for rotary switches: A case study. The TQM Journal, 24(5), 461–475.

Wang, C. H., & Wu, H. S. (2014). A novel framework to evaluate programmable logic controllers: A fuzzy MCDM perspective. Journal of Intelligent Manufacturing (in Press).

Wang, Y. M., Chin, K. S., Poon, G. K. K., & Yang, J. B. (2009). Risk evaluation in failure mode and effects analysis using fuzzy weighted geometric mean. Expert Systems with Applications, 36(2), 1195–1207.

Zadeh, L. A. (1965). Fuzzy sets. Information and Control, 8(3), 338–353.

Zadeh, L. A. (1975a). The concept of a linguistic variable and its application to approximate reasoning-I. Information Sciences, 8(3), 199–249.

Zadeh, L. A. (1975b). The concept of a linguistic variable and its application to approximate reasoning-II. Information Sciences, 8(4), 301–357.

Zhang, Z. F., & Chu, X. N. (2011). Risk prioritization in failure mode and effects analysis under uncertainty. Expert Systems with Applications, 38(1), 206–214.

Acknowledgments

The authors express sincere appreciation to the editor and reviewers for their constructive comments and suggestions which are very helpful in improving the quality of the paper. This work was supported by the National Natural Science Foundation of China (No. NSFC 71272177/G020902) and the funds of the Innovation Program of Shanghai Municipal Education Commission (No. 12ZS101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, HC., Chen, YZ., You, JX. et al. Risk evaluation in failure mode and effects analysis using fuzzy digraph and matrix approach. J Intell Manuf 27, 805–816 (2016). https://doi.org/10.1007/s10845-014-0915-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0915-6