Abstract

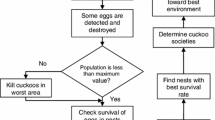

Cuckoo is a new evolutionary algorithm which is inspired by lifestyle of bird family. This study proposes Cuckoo algorithm for prediction of the surface roughness of Abrasive Water Jet (AWJ). Several prediction models with different initial eggs were developed and analyzed to investigate the best predicted surface roughness value. The paired sample t-test was used to demonstrate the validity of the results. Throughout this study, it was evidence that the Cuckoo algorithm could improve machining performances of the AWJ. The result shows that the more initial eggs were considered, a much lower predicted value of surface roughness was obtained. When the initial eggs increase, the value of the best parameters become nearer to the goal point. It was found that Cuckoo algorithm is capable for giving an improved surface roughness as it outperformed the results of two established computational techniques, artificial neural network and support vector machine.

Similar content being viewed by others

References

Adnan, M. R. H. M., Sarkheyli, A., Zain, A. M., & Haron, H. (2013). Fuzzy logic for modeling machining process: A review. Artificial Intelligence Review, doi:10.1007/s10462-012-9381-8.

Al-Zubaidi, S., Ghani, J. A., & Haron, C. H. C., et al. (2013). Optimization of cutting conditions for end milling of Ti6Al4V alloy by using a Gravitational Search Algorithm (GSA). Meccanica, pp. 1–15.

Benardos, P. G., & Vosniakos, G. C. (2003). Predicting surface roughness in machining: A review. International Journal of Machine Tools and Manufacture, 43(8), 833–844.

Çaydaş, U., & Hasçalık, A. (2008). A study on surface roughness in abrasive waterjet machining process using artificial neural networks and regression analysis method. Journal of Materials Processing Technology, 202(1), 574–582.

Çaydaş, U., & Ekici, S. (2012). Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. Journal of Intelligent Manufacturing, 23(3), 639–650.

Deris, A. M., Zain, A. M., & Sallehuddin, R. (2013). Hybrid GR-SVM for prediction of surface roughness in abrasive water jet machining. Meccanica, pp. 1–9.

Ergur, H. S., & Oysal, Y. (2013). Estimation of cutting speed in abrasive water jet using an adaptive wavelet neural network. Journal of Intelligent Manufacturing, pp. 1–11.

Farshidianfar, A., Saghafi, A., Kalami, S. M., & Saghafi, I. (2012). Active vibration isolation of machinery and sensitive equipment using H \(\infty \) control criterion and particle swarm optimization method. Meccanica, 47(2), 437–453.

Johari, N. F., Zain, A. M., Mustaffa, N. H., & Udin, A. (2013). Firefly algorithm for optimization problem. Applied Mechanics and Materials, 421, 512–517.

Jung, J. Y. (2002). Manufacturing cost estimation for machined parts based on manufacturing features. Journal of Intelligent Manufacturing, 13(4), 227–238.

Kamaruzaman, A. F., Zain, A. M., Yusuf, S. M., & Udin, A. (2013). Levy flight algorithm for optimization problems-a literature review. Applied Mechanics and Materials, 421, 496–501.

Liu, P., Xu, J. H., & Fu, Y. C. (2011). Cutting force and its frequency spectrum characteristics in high speed milling of titanium alloy with a polycrystalline diamond tool. Journal of Zhejiang University Science A, 12(1), 56–62.

Markopoulos, A. P., Manolakos, D. E., & Vaxevanidis, N. M. (2008). Artificial neural network models for the prediction of surface roughness in electrical discharge machining. Journal of Intelligent Manufacturing, 19(3), 283–292.

Mohamad, A., Zain, A. M., Bazin, N. E. N., & Udin, A. (2013). Cuckoo search algorithm for optimization problems—a literature review. Applied Mechanics and Materials, 421, 502–506.

Mokhtar, A., & Xu, X. (2011). Machining precedence of 21/2D interacting features in a feature-based data model. Journal of Intelligent Manufacturing, 22(2), 145–161.

Moola, M. R., Gorin, A., & Hossein, K. A. (2012). Optimization of various cutting parameters on the surface roughness of the machinable glass ceramic with two flute square end mills of micro grain solid carbide. International Journal of Precision Engineering and Manufacturing, 13(9), 1549–1554.

Munawar, M., Chen, J. C. S., & Mufti, N. A. (2011). Investigation of cutting parameters effect for minimization of surface roughness in internal turning. International Journal of Precision Engineering and Manufacturing., 12(1), 121–127.

Raeisi, E., & Ziaei-Rad, S. (2012). The worst response of mistuned bladed disk system using neural network and genetic algorithm. Meccanica, doi:10.1007/s11012-012-9607-5.

Rajabioun, R. (2011). Cuckoo optimization algorithm. Applied Soft Computing, 11(8), 5508–5518.

Raju, K. V. M. K., Janardhana, G. R., & Kumar, P. N. (2011). Optimization of cutting conditions for surface roughness in CNC end milling. International Journal of Precision Engineering and Manufacturing., 12(3), 383–391.

Ridwan, F., Xu, X., & Liu, G. (2012). A framework for machining optimisation based on STEP-NC. Journal of Intelligent Manufacturing., 23(3), 423–441.

Salgado, D. R., Alonso, F. J., Cambero, I., & Marcelo, A. (2009). In-process surface roughness prediction system using cutting vibrations in turning. The International Journal of Advanced Manufacturing Technology, 43(1), 40–51.

Sardashti, A., Daniali, H. M., & Varedi, S. M. (2013a). Optimal free-defect synthesis of four-bar linkage with joint clearance using PSO algorithm. Meccanica, doi:10.1007/s11012-013-9699-6.

Sarkheyli, A., Zain, A. M., & Sharif, S. (2013b). A multi-performance prediction model based on ANFIS and new modified-GA for machining processes. Journal of Intelligent Manufacturing, doi:10.1007/s10845-013-0828-9.

Selvan, M. C. P., & Raju, D. N. M. S. (2011). Selection of process parameters in abrasive waterjet cutting of copper. International Journal of Advanced Engineering Sciences and Technologies, 7(2), 254–257.

Sharma, V. S., Dhiman, S., Sehgal, R., & Sharma, S. K. (2008). Estimation of cutting forces and surface roughness for hard turning using neural networks. Journal of Intelligent Manufacturing, 19(4), 473–483.

Xu, J. H., Zhang, S. Y., Tan, J. R., & Sa, R. N. (2013). Collisionless tool orientation smoothing above blade stream surface using NURBS envelope. Journal of Zhejiang University Science A, 14(3), 187–197.

Yang, X. S., & Deb, S. (2009). Cuckoo search via Lévy flights., In: Nature & biologically inspired computing, 2009. NaBIC 2009. World Congress on (pp. 210–214). IEEE.

Yusup, N., Sarkheyli, A., Zain, A. M., Hashim, S. Z. M., & Ithnin, N. (2013). Estimation of optimal machining control parameters using artificial bee colony. Journal of Intelligent Manufacturing, pp. 1–10.

Yusup, N., Zain, A. M., & Hashim, S. Z. M. (2012). Evolutionary techniques in optimizing machining parameters: Review and recent applications (2007–2011). Expert System with Applications, 39, 9909–9927.

Zain, A. M., Haron, H., & Sharif, S. (2010a). Application of GA to optimize cutting conditions for minimizing surface roughness in end milling machining process. Expert System with Applications, 37, 4650–4659.

Zain, A. M., Haron, H., & Sharif, S. (2010b). Prediction of surface roughness in the end milling machining using artificial neural network. Expert System with Applications, 37, 1755–1768.

Zain, A. M., Haron, H., & Sharif, S. (2010c). Simulated annealing to estimate the optimal cutting conditions for minimizing surface roughness in end milling Ti-6Al-4V. Machining Science and Technology, 14, 43–62.

Zain, A. M., Haron, H., & Sharif, S. (2011b). Integration of simulated annealing and genetic algorithm to estimate optimal solutions for minimising surface roughness in end milling Ti-6AL-4V. International Journal of Computer Integrated Manufacturing, 24, 574–592.

Zain, A. M., Haron, H., & Sharif, S. (2011a). Estimation of the minimum machining performance in the abrasive waterjet machining using integrated ANN-SA. Expert Systems with Applications, 38(7), 8316–8326.

Zain, A. M., Haron, H., & Sharif, S. (2011c). Genetic algorithm and simulated annealing to estimate optimal process parameters of the abrasive waterjet machining. Engineering with Computers, 27, 251–259.

Zain, A. M., Haron, H., & Sharif, S. (2012a). Integrated ANN-GA for estimating the minimum value for machining performance. International Journal of Production Research, 50(1), 191–213.

Zain, A. M., Haron, H., Qasem, S. N., & Sharif, S. (2012b). Regression and ANN models for estimating minimum value of machining performance. Applied Mathematical Modelling, 36(4), 1477–1492.

Zainal, N., Zain, A. M., Radzi, N. H. M., & Udin, A. (2013). Glowworm swarm optimization (GSO) algorithm for optimization problems: A state-of-the-art review. Applied Mechanics and Materials, 421, 507–511.

Acknowledgments

Special appreciation to reviewer(s) for useful advices and comments. The authors greatly acknowledge Soft Computing Research Group (SCRG), Research Management Centre (RMC) UTM and Ministry of Higher Education Malaysia (MOHE) for financial support through the Exploratory Research Grant Scheme (ERGS) No. R.J130000.7828.4L087

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohamad, A., Zain, A.M., Bazin, N.E.N. et al. A process prediction model based on Cuckoo algorithm for abrasive waterjet machining. J Intell Manuf 26, 1247–1252 (2015). https://doi.org/10.1007/s10845-013-0853-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0853-8