Abstract

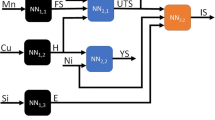

Extrusion of aluminium alloys is a complex process which depends on the characteristics of the material and on the process parameters (initial billet temperature, extrusion ratio, friction at the interfaces, die geometry etc.). The temperature profile at the die exit, largely influences microstructure, mechanical properties, and surface quality of an extruded product, consequently it is the most important parameter for controlling the process. In turn the temperature profile depends on other process variables whose right choice is fundamental to avoid surface damage of the extruded product. In the present work, two neural networks were implemented to optimize the aluminium extrusion process determining the temperature profile of an Al 6060 alloy (UNI 9006/1) at the exit of induction heater (ANN1) and at the exit of the die (ANN2). The three-layer neural networks with Levemberg Marquardt algorithm were trained with the experimental data from the industrial process. The temperature profiles, predicted by the neural network, closely agree with experimental values.

Similar content being viewed by others

References

Ajiboye J.S., Adeyemi M.B. (2008) Effects of extrusion variables on temperature distribution in axisymmetric extrusion process. International Journal of Mechanical Sciences 50: 522–537. doi:10.1016/j.ijmecsci.2007.08.006

Castle, A. F. (1996). Temperature control in aluminium extrusion. Proceedings of the Sixth International Aluminium Extrusion Technology Seminar (Vol. 1, pp.181–184). Chicago: Aluminium Association and Extruders Council.

Chanda T., Zhou J., Duszczyk J. (2000) FEM analysis of aluminium extrusion through square and round dies. Materials & Design 21: 322–335. doi:10.1016/S0261-3069(99)00073-4

Duan X., Velay X., Sheppard T. (2004) Application of finite element method in the hot extrusion of aluminium alloys. Materials Science and Engineering A 369: 66–75. doi:10.1016/j.msea.2003.10.275

Fausett L.V. (1994) Fundamentals of neural networks: Architectures, algorithms and applications. Englewood Cliffs, NJ, Prentice Hall

Hsiang S., Kuo J. (2005) Application of ANN to the hot extrusion of magnesium alloy sheets. International Journal of Advanced Manufacturing Technology 25: 292–300. doi:10.1007/s00170-003-1828-2

Hsiang S., Kuo J., Yang F. (2006) Using artificial neural networks to investigate the influence of temperature on hot extrusion of AZ61 magnesium alloy. Journal of Intelligent Manufacturing 17: 191–201. doi:10.1007/s10845-005-6636-0

Karabay S., Yilmaz M., Zeren M. (2005) Investigation of extrusion ratio effect on mechanical behaviour of extruded alloy AA-6101 from the billets homogenised-rapid quenched and as-cast conditions. Journal of Materials Processing Technology 160: 138–147. doi:10.1016/j.jmatprotec.2004.05.025

Levenberg K. (1944) A method for the solution of certain nonlinear problems in least squares. Quarterly of Applied Mathematics 2: 164–168

Marquardt D. (1963) An algorithm for least squares estimation of nonlinear parameters. Journal of the Society for Industrial and Applied Mathematics 11: 431–441

Zhou J., Li L., Duszczyk J. (2004) Computer simulated and experimentally verified isothermal extrusion of 7075 aluminium through continuous ram speed variation. Journal of Materials Processing Technology 146: 203–212. doi:10.1016/j.jmatprotec.2003.10.018

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lucignano, C., Montanari, R., Tagliaferri, V. et al. Artificial neural networks to optimize the extrusion of an aluminium alloy. J Intell Manuf 21, 569–574 (2010). https://doi.org/10.1007/s10845-009-0239-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-009-0239-0