Abstract

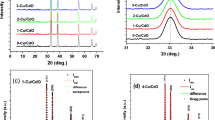

Radio frequency (RF) magnetron sputtering was used to fabricate Cu-doped Cu2O thin using a gas mixture containing 80% Ar and 20% N2 at room temperature. The Cu2O ceramics containing different concentrations of Cu powder (1–7 wt%) were considered to be the sputtering targets. A highly dense Cu-doped Cu2O target was essential to obtain excellent quality Cu2O films; this target can be obtained via the hot-pressing process because the low melting point (1084.6 °C) of Cu allows enhanced densification of the Cu2O target through a liquid-phase wetting mechanism. X-ray diffraction (XRD), Raman spectroscopy, field emission scanning electron microscopy (FESEM), and transmission electron microscopy (TEM) were performed to characterize the Cu2O film microstructure. Our results denoted that Cu doping enhances the densification and increases the grain size of the Cu2O films. Further, the crystal structures of the films changed from CuO and Cu4O3 to Cu2O when the Cu doping concentration increased from 1 to 7 wt%. A dense and well-defined columnar morphology can be observed when TEM was used to observe the film microstructure. Subsequently, the electrical and optical properties of the Cu2O thin films were evaluated at different Cu concentrations. The electrical resistivity of the Cu2O films became 8.6 Ω·cm when the Cu doping concentration was 7 wt%, corresponding to a carrier density of 9.8 × 1016 cm−3 and a mobility of 7.5 cm2/Vs. Furthermore, the optical transmission of the Cu2O films doped with Cu was greater than 60%. The band gaps of the films ranged from 2.32 to 2.54 eV depending on the copper oxide phases present in the films.

Similar content being viewed by others

References

Y. Nakano, S. Saeki, T. Morikawa, Appl. Phys. Lett. 94, 022111 (2009)

W. Zheng, Y. Chen, X. Peng, K. Zhong, Y. Lin, Z. Huang, Materials 11, 1253 (2018)

D. Ozaslana, O.M. Ozkendir, M. Gunes, Y. Ufuktepea, C. Gumus, Optik 157, 1325 (2018)

D.K. Negar, K. Reza, K.E. Saeideh, M.P. Saeid, R. Seeram, J.Y .Hu 9, 1011 (2019)

A. Rydosz, Coating 8, 425 (2018)

A. Da Cas Viegas, Thin Solid Films 562, 144 (2014)

L. Zhang, Q. Li, H. Xue, H. Pang, ChemSusChem 11, 1581 (2018)

T. Minami, Y. Nishi, T. Miyata, Y. Nishi, Solar Energy 105, 206 (2014)

Y. Aljlan, F. Placido, H.O. Chu, R.D. Bold, L. Fleming, D. Gibson, Thin Solid Films 642, 45 (2017)

Y.G. Lee, J.R. Wang, M.J. Chuang, D.W. Chen, K.H. Hou, Int. J. Electrochem. Sci. 12, 507 (2017)

J.B. Liang, N. Kishi, T. Soga, T. Jimbo, M.S. Ahmed, Thin Solid Film 520, 2679 (2012)

L. Armelao, D. Barreca, M. Bertapelle, G. Bottaro, C. Sada, Thin Solid Films 442, 48 (2003)

X. Liu, M. Xu, X. Zhang, W. Wang, X. Feng, A. Song, Appl. Surf. Sci. 435, 305 (2018)

H. Kim, M.Y. Lee, S.H. Kim, S.I. Bae, K.Y. Ko, H. Kim, K.W. Kwon, J.H. Hwang, D.J. Lee, Applied Surface Science 349, 673 (2015)

H. Zhu, J. Zhang, C. Li, F. Pan, T. Wang, B. Huang, Thin Solid Films 517, 5700 (2009)

H.C. Lu, C.L. Chu, C.Y. Lai, Y.H. Wang, Thin Solid Films 517, 4408 (2009)

S. Masudy-Panah, K. Radhakrishnan, A. Kumar, T.I. Wong, R. Yi, G.K. Dalapati, J. of Appl. Phys. 118, 225301 (2015)

Y. Wang, S. Lany, J. Ghanbaja, Y. Fagot-Revurat, Y.P. Chen, F.S. Oldera, D. Horwat, F. Mucklich, J.F. Pierson, Phys. Rev. B 94, 245418 (2016)

V.F. Drobny, D.L. Pulfrey, Thin Solid Films 61, 89 (1979)

S.C. Siah, Y.S. Lee, Y. Segal, T. Buonassisi, J. Appl. Phys. 112, 084508 (2012)

H.J. Li, C.Y. Pu, C.Y. Ma, S.H. Li, W.J. Dong, S.Y. Bao, Q.Y. Zhang, Thin Solid Films 520, 212 (2011)

S.H. Lee, S.J. Yun, J.W. Lim, ETRI Journal 35, 1156 (2013)

J.E. Morris, M.I. Ridge, C.A. Bishop, R.P. Howson, J. Appl. Phys. 51, 1847 (1980)

S. Chaudhuri, J. Bhattacharyya, A.K. Pal, Thin Solid Films 148, 279 (1987)

W. Zheng, Y. Chen, X. Peng, K. Zhong, Y. Lin, Z. Huang, Materials 11071253, 11 (2018)

L. Debbichi, M.C. Marco de Lucas, J.F. Pierson, P. Krüger, J. Phys. Chem. C 116, 10232 (2012)

M. Ivanda, D. Waasmaier, A. Endriss, J. Ihringer, A. Kirfel, W. Kiefer, J. Raman Spectrosc. 28, 487 (1997)

H.L. Hartnagel, A.L. Dawar, A.K. Jain, C. Jagadish, Semiconducting transparent thin films, (Institute of Physics Publishing, Philadelphia, 1995)

B. Balamurugan, B.R. Mehta, Thin solid films 96, 90 (2001)

A.A. Ogwu, E. Bouquerel, O. Ademosu, S. Moh, E. Crossan, F. Placido, J. Phys. D Appl. Phys. 38, 266 (2005a)

S. Dolai, R. Dey, S. Das, S. Hussain, R. Bhar, A.K. Pal, J. Alloy. Comp. 724, 456 (2017)

J.F. Pierson, A. Thobor-Keck, A. Billard, Appl. Surf. Sci. 210, 359 (2003)

P.E.D. Morgan, D.E. Partin, B.L. Chamberland, M.O. Keeffe, J. Solid State Chem. 37, 33 (1996)

Acknowledgments

The authors are grateful to Ministry of Science and Technology of Taiwan for the financial support to this work under contract no. MOST-105-2221-E-214-032.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Houng, B., Wu, J.K., Yeh, P.C. et al. Effect of Cu addition on the properties of the RF magnetron-sputtered Cu2O thin films. J Electroceram 45, 129–134 (2020). https://doi.org/10.1007/s10832-021-00234-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-021-00234-x