Abstract

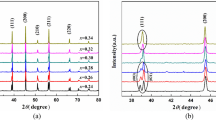

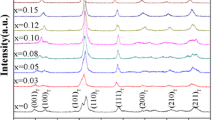

Lead-free (1-x)BiFeO3–xBaTiO3 [(1-x)BF-xBT] piezoelectric ceramics in the range of large BF concentrations were prepared by conventional oxide-mixed method at various sintering temperatures. The sintering temperatures have a significant effect on the microstructure of the ceramics, and the composition has a remarkable effect on optimal sintering temperature of the ceramics, which are closely related with piezoelectric properties. The grain size increased with increasing sintering temperature and the optimal sintering temperature increased with increasing BT content. The ceramics with x = 0.275 sintered at 990 °C exhibit enhanced electrical properties of d 33 = 136pC/N and k p = 0.312 due to the polarization rotation mechanisms at MPB and desired microstructure. These results show that the ceramic with x = 0.275 is a promising lead-free high-temperature piezoelectric material.

Similar content being viewed by others

References

B. Jaffe, W.R. Cook, H. Jaffe, Academic, London, (1971)

Y. Chen, J. Zhu, D. Xiao, B. Qin, Y. Jiang, Mater. Lett. 62, 3567 (2008)

F. Gao, R. Hong, J. Liu, Z. Li, L. Cheng, C. Tian, J. Alloys Compd. 475, 619 (2009)

S. Chen, X.L. Dong, C.L. Mao, F. Cao, J. Am. Ceram. Soc. 89, 3270 (2006)

R.E. Eitel, C.A. Randall, T.R. Shout, Jpn. J. Appl. Phys. 40, 5999 (2001)

R.E. Eitel, C.A. Randall, T.R. Shrout, Jpn. J. Appl. Phys. 41, 2099 (2002)

M.R. Suchomel, P.K. Davies, J. Appl. Phys. 96, 4405 (2004)

D.I. Woodward, L.M. Reaney, R.E. Eitel, J. Appl. Phys. 94, 3313 (2003)

J. Cheng, N. Li, L.E. Cross, J. Appl. Phys. 94, 5153 (2003)

F. Gao, R. Hong, J. Liu, J. Euro. Ceram. Soc. 29, 1687 (2009)

S. Zhang, R. Xia, C.A. Randall, T.R. Shrout, R.R. Duan, R.F. Speyer, J. Mater. Res. 20, 2067 (2005)

S.M. Choi, C.J. Striger, T.R. Shrout, C.A. Randall, J. Appl. Phys. 98, 034108 (2005)

J. Cheng, R. Eitel, L.E. Cross, J. Am. Ceram. Soc. 86, 2111 (2003)

Z. Yao, L. Peng, H. Liu, H. Hao, M. Cao, Z. Yu, J. Alloys Compd. 509, 5637 (2011)

R. Rai, A. Kholkin, S. Pandey, N.K. Singh, J. Alloys Compd. 488, 459 (2009)

H. Ogihara, C.A. Randall, S. Trolier-Mckinstry, J. Am. Ceram. Soc. 92, 110 (2009)

M.M. Kumar, A. Srinivas, S.V. Suryanarayana, J. Appl. Phys. 87, 855 (2000)

S.O. Leontsevw, R.E. Eitel, J. Am. Ceram. Soc. 92, 2957 (2009)

C.C. Huang, D.P. Cann, J. Appl. Phys. 104, 024117 (2008)

Q. Zhang, Z. Li, F. Li, Z. Xu, J. Am. Ceram. Soc. 94, 4335 (2011)

B. Xiong, H. Hao, S. Zhang, H. Liu, M. Cao, J. Am. Ceram. Soc. 94, 3412 (2011)

S. Wada, K. Yamato, P. Pulpan, N. Kumada, B.Y. Lee, T. Iijima, C. Moriyoshi, Y. Kuroiwa, J. Appl. Phys. 108, 094114 (2010)

I. Fujii, R. Mitsui, K. Nakashima, N. Kumada, M. Shimada, Jpn. J. Appl. Phys. 50, 09ND07 (2011)

Y.J. Lee, J.S. Kim, S.H. Han, H.-W. Kang, H.-G. Lee, C. Il Cheon, J. Korean Phys. Soc. 61, 947 (2012)

H. Yang, C. Zhou, X. Liu, Q. Zhou, G. Chen, H. Wang, W. Li, Mater. Res. Bull. 47, 4233 (2012)

Q. Zhou, C. Zhou, H. Yang, G. Chen, W. Li, H. Wang, J. Am. Ceram. Soc. 95, 3889 (2012)

C. Zhou, A. Feteira, X. Shan, H. Yang, Q. Zhou, J. Chen, W. Li, H. Wang, Appl. Phys. Lett. 101, 032901 (2012)

R. Zuo, S. Su, Y. Wu, J. Fu, M. Wang, L. Li, Mater. Chem. Phys. 110, 311 (2008)

F. Rubio-Marcos, P. Marchet, T. Merle-Méjean, J.F. Fernandez, Mater. Chem. Phys. 123, 91 (2008)

C.A. Randall, N. Kim, J.-P. Kucera, W. Cao, T.R. Shrout, J. Am. Ceram. Soc. 81, 677 (1998)

W. Cao, C.A. Randall, J. Phys. Chem. Solids 57, 1499 (1996)

W. Liu, X. Ren, Phys. Rev. Lett. 103, 257602 (2009)

J. Iniguez, D. Vanderbilt, L. Bellaiche, Phys. Rev. B 67, 224107 (2003)

C. Zhou, H. Yang, Q. Zhou, G. Chen, W. Li, H. Wang, J. Mater. Sci. Mater. Electron. doi:10.1007/s10854-012-0996-y

Acknowledgments

This work was supported by the National Nature Science Foundation of China (61261012) Guangxi Science Foundation (2010GXNSFD013007 and 2010GXNSFB013010) and Guangxi Education Department Foundation (201012MS083) and Guangxi Key Laboratory of Information Materials (1110908-09-Z).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cen, Z., Yang, H., Zhou, C. et al. Effect of sintering temperature on microstructure and piezoelectric properties of Pb-free BiFeO3–BaTiO3 ceramics in the composition range of large BiFeO3 concentrations. J Electroceram 31, 15–20 (2013). https://doi.org/10.1007/s10832-013-9803-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-013-9803-2