Abstract

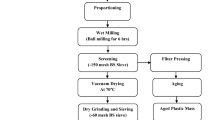

Functionally graded ferroelectric ceramics (FGM) have been fabricated for pyroelectric applications by an aqueous tape casting technology. The FGM produced in this study consisted of a porous Lead Zirconate Titanate (PZT) tape-cast ceramic, which was made by starch inclusions; sandwiched between two dense PZT layers by stacking and lamination. This paper investigates the effect of porosity on the microstructure and electrical properties of the PZT FGM samples produced. The microstructure of the porous and laminated sintered structures was studied using Scanning Electron Microscopy (SEM). The grain size of the porous layer tended to decrease with increasing corn-starch content. The dielectric constant and pyroelectric coefficient of the FGM both showed decreasing behaviour with increasing porosity.

Similar content being viewed by others

References

J. Luyten, J. Cooymans, A. De Wilde, and I. Thijis, Key Engineering Materials, 206–213, 1937, (2002).

S. F. Corbin, Journal of American Ceramic Society, 82, 1693 (1999).

A. Navarro PhD Thesis, Cranfield University, United Kingdom (2001).

Z. He, J. Ma, R. Zhang, and T. Li, Journal of European Ceramic, Society, 23, 1943 (2003).

M. Hosseini, S.J. Moosavi, Ceramics International, 26, 541 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Navarro, A., Whatmore, R.W. & Alcock, J.R. Preparation of Functionally Graded PZT Ceramics Using Tape Casting. J Electroceram 13, 413–415 (2004). https://doi.org/10.1007/s10832-004-5134-7

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10832-004-5134-7