Abstract

In recent years, the interest in using seaweed for the sustainable production of commodities has been increasing as seaweeds contain many potentially worthwhile compounds. Thus, the extraction and refining processes of interesting compounds from seaweeds is a hot research topic but has been found to have problems with profitability for novel applications. To increase the economic potential of refining seaweed biomass, the content of the compounds of interest should be maximized, which can potentially be achieved through optimization of cultivation conditions. In this study, we studied how the monosaccharide composition of the green seaweed species Ulva fenestrata is influenced by the abiotic factors; irradiance, temperature, nitrate, phosphate, and pCO2. It was evident that lower nitrate concentration and cultivation at elevated temperature increased monosaccharide contents. A 70% increase in iduronic acid and a 26% increase in rhamnose content were seen under elevated irradiance and temperature conditions, though the absolute differences in monosaccharide concentration were small. Irradiance and nitrate impacted the ratio between iduronic and rhamnose, which is an indicator of the ulvan structure. These results could potentially be utilized to coax the ulvan towards specific bioactivities, and thus have a considerable impact on a potential biorefinery centered around Ulva.

Similar content being viewed by others

Introduction

To enable a more sustainable society, there is currently a push to find more sources of biomass for utilization in biorefineries. One type of biomass that has been receiving an increased interest in recent years is seaweed. Today only a few seaweed species are cultivated and/or harvested for direct use as food or for extraction of hydrocolloidal polysaccharides. However, polysaccharides in seaweeds are diverse, and several are known to have interesting properties, but both technical and economic challenges remain before novel and economically sustainable business’ can form (Golberg et al. 2020). One group of species known for their interesting components, not only polysaccharides, are the green algae Ulva spp. (some previously named Enteromorpha). They are known for being opportunistic species with high growth rates and sometimes causing green tides around the world (Smetacek and Zingone 2013), but so far, their commercial utilization are limited to direct food use. Ulva spp. contain several polysaccharides: cellulose, starch, xyloglucan, glucuronan, and ulvan (Lahaye and Robic 2007), of which ulvan is a potential high-value product as it has been found to have antioxidant, anticoagulative, immunostimulative, immunomodulative, cancer chemopreventative, and cytotoxic activities (Kaeffer et al. 1999; Qi et al. 2005a, 2005b; Castro et al. 2006; Mao et al. 2006; Leiro et al. 2007; Kim et al. 2011; Tabarsa et al. 2012; Hussein et al. 2015; Abd-Ellatef et al. 2017). Ulvan is a cell-wall polysaccharide consisting of repeating dimers of rhamnose and either xylose, glucose, glucuronic acid, or iduronic acid, of which rhamnose and xylose can be sulfated (Lahaye and Robic 2007). The sulfation has been shown to be important for the biological activities (Qi et al. 2005a; Leiro et al. 2007), but to our knowledge, the effects of variable monosaccharide sequence and composition on the activity of ulvan have not been evaluated. The monosaccharide sequence, however, is known to be an important factor for the biological function of the anticoagulant heparin (Esko and Selleck 2002), which shares some structural elements with ulvan as it is also composed of disaccharides of sulfated neutral sugars with glucuronic or iduronic acid moieties attached (Rabenstein 2002). Therefore, it is important to study in detail what influences the composition of ulvan.

The monosaccharide rhamnose is an interesting product in itself, as it is commonly used in industry for production of flavoring compounds. Rhamnose is also a potential raw material for the production of rhamnolipids, which are bio-surfactants commercially produced from the pathogenic bacterium Pseudomonas aeruginosa. The production results in complex mixtures requiring advanced downstream processing (Muller et al. 2012). Chemical synthesis or biocatalyst production instead of the current fermentation process could allow not only tailored surfactant production but also larger yields of the desired products and lower recovery costs. Similarly to rhamnose, iduronic acid could be used for chemical synthesis of potentially valuable compounds, e.g., the glucosaminoglycan heparin. These have not been explored fully as there is, at the moment, no large scale source of commercial iduronic acid (Mohamed and Ferro 2015). For now, the profitability of seaweed cultivation is questionable, especially in Europe due to the high costs of producing biomass (Palatnik and Zilberman 2017). One way to maximize the value of produced seaweed biomass is to use cultivation conditions that elevate content of high value compounds, such as rhamnose.

Controlling the properties of produced biomass has been identified as a key challenge for seaweed industrial production, and composition is affected by several factors (Hafting et al. 2015). The impact of some abiotic cultivation factors (temperature, illumination, nutrients, and pCO2) on the carbohydrate composition of Ulva spp. has been investigated previously (Mohsen et al. 1973a,; 1973b; Gómez Pinchetti et al. 1998; Wang et al. 2007; Kumari et al. 2014; Gao et al. 2017, 2018; He et al. 2018; Chen et al. 2019). However, the total carbohydrate content is sometimes calculated by taking the difference between total weight and other biochemical components, e.g., (Gao et al. 2017, 2018), and when carbohydrates are measured directly the resolution is often poor, e.g., (Mohsen et al. 1973a, 1973b; Gómez Pinchetti et al. 1998; Kumari et al. 2014; Chen et al. 2019). To our knowledge, there are no studies of the relationship between cultivation conditions and the monosaccharide composition in Ulva spp. There is also a lack of studies on carbohydrates with more than a few abiotic factors being altered. However, Kumari et al. (2014) studied the impact on the total carbohydrate content in Ulva lactuca and found that nutrient addition of N and P caused decreased carbohydrate contents. Furthermore, Chen et al. (2019) found that pCO2 had no effect on soluble carbohydrate content. Therefore, there is room for a comprehensive study of relevant abiotic factors in tank cultivation and their effect on the monosaccharide content of Ulva fenestrata.

In this study, we investigated how the monosaccharide profile of the northern hemisphere sea lettuce (Ulva fenestrata) is affected by different cultivation conditions to identify how the carbohydrate content, and particularly high-value monosaccharides, can be elevated. The investigated environmental factors were tested in three experiments; (i) nitrogen and phosphorous addition, (ii) temperature and irradiance, and (iii) pCO2, in fully crossed designs to investigate possible interaction effects between the tested factors. To our knowledge, this is the first study that provides such comprehensive details into the changes of the monosaccharide composition in Ulva due to varied cultivation conditions. Optimized cultivation conditions for the potential high-value products could significantly improve the economic case for an industry around bioactive Ulva polysaccharides.

Materials and methods

Ulva fenestrata cultivation

The effect of different irradiance, temperature, nutrient, and pCO2 levels on the monosaccharide profile of U. fenestrata were tested in three different manipulative experiments. The experiments were performed using 15-L aquaria supplied with running filtered (5 μm + UV treated) seawater at 9 L h−1. Thus, under unmodified (ambient) conditions, the experiments had the following properties; nitrate < 5 μM, phosphate < 1 μM, temperature at 13–14 °C and with bubbling of air, a pCO2 ≈ 400 ppm and agitation were achieved. The starting seaweed material has been utilized in tank cultivations for some time at Tjärnö Marine Laboratory (58° 52′ 36.4″ N 11° 6′ 42.84″ E) and was previously identified as U. fenestrata (Genebank, accession numbers BankIt2249282 Seq1: MN240309, Seq2: MN240310, Seq3: MN240311), through sequencing of the tufA gene (Steinhagen et al. 2019). Experimental samples were taken from each experiment and were frozen, lyophilized, homogenized, and stored at < − 20 °C until further analysis.

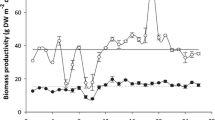

The first experiment was performed in June 2018 in a temperature-controlled room where irradiance (light source, OSRAM Lumilux Cool daylight L 58 W/865) at three levels and temperature at two levels were manipulated in a fully crossed design (n = 6, i.e., a total of 36 aquaria). The levels of irradiance were; low = 50, medium = 100, and high = 160 μmol photons m−2 s−1 obtained by shading with layers of semi-opaque plastic netting and run in a 16:8 h light:dark cycle. The two levels of temperature were 13 °C (ambient) and 18 °C (heated by submerged heaters, EHEIM Aquarium heaters, 600-1000 L, 230 V, 300 W). Nutrients were at ambient levels. The cultivations were started by adding 12 cm2 discs of U. fenestrata to a density of 0.14 g L−1, and the seaweeds were cultivated for 7 days.

In the second experiment, performed in October 2018 in a temperature-controlled room, the nitrogen (three levels) and phosphorus (two levels) levels were manipulated in a fully crossed design (n = 6, i.e., a total of 36 aquaria) with temperature at ambient conditions. The same lamps were used as in the first experiment at an average irradiance of 110 μmol photons m−2 s−1 with a 16:8 h light:dark cycle. Nutrients were added in the morning each day of the experiment by turning off the running water and adding nutrients from a stock solution of NaNO3 and Na2HPO4, to a final concentration of 150 (medium), and 500 (high) μM nitrate, and 50 (high) μM phosphate. Ambient seawater was used for the low nutrient level. The seaweeds were allowed to assimilate nutrients for 2 h, after which the water flow was turned back on. During the time when the water turned off, agitation was only provided by the bubbling of air. The experiment was started by adding discs of seaweed at 0.71 g L−1 and lasted for 5 days.

The third experiment was performed with pCO2 being manipulated (three levels) in October 2018 with constant seawater flow (9 L h−1) from header tanks (a total of 6 header tanks, n = 2) to 15-L aquaria giving ambient nutrient levels and temperature. The aquaria were placed in a greenhouse receiving natural light with a 10:14 h light:dark cycle and average irradiance of 50 μmol photons m−2 s−1 (between 11:00 am and 01:00 pm). Control algae were maintained at ambient pCO2 (target pCO2 = 400 ppm, pH = 8.1), while experimental algae were exposed to either low pCO2 (target pCO2 = 200 ppm, pH = 8.4) or high pCO2 (target pCO2 = 2500, pH = 7.4). The different levels of pCO2/pH were achieved via a pH controller (Aqua Medic, Germany, NBS-calibrated) by adding and mixing pure CO2 and air from which CO2 was removed (AGA, Sweden). The pCO2 was monitored using an LI-850 CO2/H2O Gas Analyzer (LI-COR Biosciences, USA). The experiment was started by adding discs of seaweed at 0.71 g L−1 and lasted for 5 days.

Carbohydrate analysis

Carbohydrates were determined by summation of monosaccharides and uronic acids from a two-step sulfuric acid hydrolysis as by Bikker et al. (2016) performed on duplicate samples with 15 mg of freeze-dried biomass. Before hydrolysis the samples were homogenized with glass beads in microcentrifuge tubes with a Tissue lyzer II (Qiagen, Germany) at 30 Hz for 1 min. Hydrolysed samples were mostly analysed within 48 h. However, due to technical failure of the instrument some samples were reanalysed from frozen (−20 °C) hydrolysed samples, which had been diluted to 4% H2SO4 for better stability (van Wychen and Laurens 2015). From technical replicates no difference could be noticed for different storage times. Sulfuric acid solutions were prepared from concentrated H2SO4 (98%, Merck). The monosaccharides and uronic acids were quantified using a high-performance anion exchange chromatography system (Thermo ScientificTM DionexTM, ICS-5000, USA) with a pulsed amperometric detector and was used with a Dionex CarbopacTM PA1 4 × 250 mm column with a 4 × 50 mm guard. The column and detector compartment were maintained at 25 °C, and a gradient program with four eluents was run for separation, Table 1. For preparing eluents, the NaOH (50% solution) and sodium acetate (≥ 99.0%, anhydrous) were purchased from Merck. The program was run with post-column addition of 0.5 mL min−1 of the 300 mM NaOH eluent. Standard curves for calculation of concentrations were in the range of 1–10 mg L−1 for d-galactose (≥ 99%, Sigma-Aldrich) and l-iduronic acid (≥ 98%, Carbosynth) and 1–100 mg L−1 for d-glucose (≥ 99.5%, Sigma-Aldrich), l-rhamnose (99%, Sigma-Aldrich), d-xylose (≥ 99%, Sigma-Aldrich) and D-glucuronic acid (≥98%, Carbosynth). The monosaccharides were assumed to originate from polysaccharides, and final concentrations were adjusted by a factor from dividing the molecular weight of the monosaccharide in a polysaccharide with the weight with the addition of water from breakage of the glycosidic bond.

Statistics

The data were analysed statistically using analysis of variance (ANOVA). The experiments with irradiance:temperature and nitrate:phosphate were analysed in separate 2-way ANOVAs with fixed 2-level factors (temperature and phosphate) and 3-level factors (irradiance and nitrate). pCO2 was analysed using a mixed model ANOVA with pCO2 as a fixed 3-level factor and header tank as a random factor nested within pCO2. Homogeneity of variances of the data was tested using Cochran’s test. No heterogeneous variances were found, and the data were not transformed. Significant differences among means were compared using the Tukey’s HSD test.

Results

Content of total carbohydrate and monosaccharides

The monosaccharide composition in Ulva fenestrata biomass was determined after full hydrolysis of the polysaccharides in samples taken from tank cultivations with altering environmental factors, irradiance, temperature, nitrate, phosphate, and pCO2. Total carbohydrates varied between 25 and 38 g (100 g)−1, Table 2, with the highest content of carbohydrates at 34–38 g (100 g)−1 found in the temperature and irradiance experiments. At elevated levels of nitrate, the lowest total carbohydrate content was found. Among the monosaccharides, glucose was dominating with contents in the range 13.2–22.5 g (100 g)−1, Table 2. Rhamnose was the second largest component at 4.62–6.92 g (100 g)−1. Rhamnose and glucose contents were both highest at the lowest pCO2 level. Xylose was also present at fairly high amounts (4.55–5.90 g (100 g)−1), while glucuronic acid was lower at 1.44–2.47 g (100 g)−1. Glucuronic acid content was highest at the intermediate level of pCO2. The content of the potential high-value monosaccharide, iduronic acid, was low as compared with the other monosaccharides (0.40–0.86 g (100 g)−1) in all experiments. The ratio between the iduronic acid and rhamnose, the two unique monomers of ulvan, ranged between 0.08 and 0.13 g g−1 and was the highest (0.12–0.13 g g−1) at intermediate illumination (at both temperatures) and at low nitrate.

Effects of cultivation conditions on content

Significant effects of cultivation conditions were evaluated by ANOVA analysis, Table 3, and for these conditions where effects were found post-hoc Tukey’s tests (p < 0.05) were done to identify significant differences between means.

Irradiance affected rhamnose and galactose and both glucuronic and iduronic acids. The content at low irradiance was significantly lower for rhamnose than at high irradiance, whereas for galactose and glucuronic acid the contents were higher at low irradiance. Significant changes in iduronic acid content were seen between all the irradiance experiments with the highest content at the intermediate irradiance level (100 μmol photons m−2 s−1). Elevated temperature had a significant effect on both total carbohydrate levels as well as all monosaccharides resulting in higher contents except for galactose. There was a combined significant effect from temperature and irradiance on glucose with the highest values reached with low irradiance and elevated temperature.

When changing nutrients levels, it was found that nitrate had a significant effect on total carbohydrates and all monosaccharides except rhamnose. For all these except galactose, there was a significant higher content at the lowest nitrate availability, i.e., ambient conditions, but no difference between the medium and high nitrate level treatments. Phosphate had fewer effects and impacted only rhamnose, xylose, and glucuronic acid, for which low phosphate, i.e., ambient conditions, resulted in higher content. For galactose, there was also a combined effect of both nitrate and phosphate. We found a significant effect of pCO2 on the amount of total carbohydrates, and the rhamnose, glucose, and glucuronic acid contents. Low pCO2 resulted in high total carbohydrates and glucose contents.

Despite the significant impacts of cultivation conditions on several monosaccharides, the actual absolute differences are small. The high-irradiance and high-temperature experiment had 26% higher rhamnose content than when both parameters were low, clearly showcasing the importance of picking the correct cultivation conditions to maximize the content of compounds crucial for a certain application. However, the nitrogen and phosphate experiment resulted in a 10% decrease instead when adding both nutrients, and for the pCO2 the change is even less.

The ratio between the iduronic acid and rhamnose was significantly affected by irradiance and nitrate level. Low nitrate conditions and intermediate irradiance resulted in significantly higher IduA/Rha ratios.

Discussion

Ulva spp. have been studied rather extensively throughout the years in many aspects. However, this research has become more complicated in recent years with new insights regarding the number of species lacking clear morphologically identification criteria. What was considered U. lactuca in the northern hemisphere has recently been molecularly identified to be U. fenestrata (Hughey et al. 2019), and this needs to be considered when comparing composition between studies. Ideally, only studies on U. lactuca performed in the northern hemisphere would be compared with the present study, as the studied material are more likely to be U. fenestrata, but this is not possible as there are very few studies performed on carbohydrate variation in Ulva spp.

Our data of total carbohydrates were distributed in the lower to middle range of what has previously been reported for Ulva spp. (Holdt and Kraan 2011). That elevated temperature has a positive effect on the carbohydrate content in Ulva spp. is supported by previous studies (Mohsen et al. 1973b; Wang et al. 2007; He et al. 2018). As for irradiance, Mohsen et al. (1973a) found that the correlation to carbohydrates is not strictly positive or negative but different for the different carbohydrate components, as was also the case for the monosaccharides in this study. That elevated availability of nitrate resulted in low total carbohydrate content, as found in this study, is in agreement with Kumari et al. (2014) and Gómez Pinchetti et al. (1998) who observed decreased soluble and insoluble carbohydrates with increased nutrients. The decrease was coupled to an increased protein content, and they found that the accumulation of carbohydrates was a response to nitrogen and phosphorus limitation, which is in contradiction to our data where phosphorus had no effect on total carbohydrates. The difference between the studies could possibly be caused by the use of natural filtered seawater in this study, which might not have had sufficiently low levels of nitrate and phosphate to cause starvation. In a study with pCO2 at two levels (400 and 1000 ppm), Chen et al. (2019) found that the soluble carbohydrate content did not change significantly. However, not all carbohydrates in Ulva are water soluble. As the sulfuric acid hydrolysis used in this study degrades both the soluble and insoluble polysaccharides found in Ulva, i.e., the overall carbohydrate content of starch and the cell-wall components cellulose, glucuronan, xyloglucan, and ulvan, it is not surprising that the result is different from that of Chen et al. (2019).

Our data showed that absolute difference in monosaccharide content was small, e.g., the difference between the highest and lowest total carbohydrate contents for the temperature/irradiance experiment was 15%, mostly due to an increase in glucose content, Table 2. This is unfortunate as other algae, e.g., Saccharina latissima at a glucose content of 41.8 g (100 g)−1 (Vilg et al. 2015), contain a much larger fraction of easily fermentable glucose containing polysaccharides than the 22 g (100 g)−1 that were observed in this study. As these seaweeds are not profitable to produce for fermentation processes (Konda et al. 2015), glucose is probably not a component that would be of interest to optimize in Ulva spp.

On the other hand, there were significant changes in the contents of the potential high-value monosaccharides rhamnose and iduronic acid. The high-value iduronic acid was found in rather low quantities. However, disaccharides with iduronic acid are well known to be notoriously difficult to hydrolyse with acid and although better methods do exist (De Ruiter et al. 1992), they are optimized for pure polysaccharide samples rather than untreated biomass. Hence, the iduronic acid content could, potentially, have been higher if the ulvan had been extracted and analysed separately. This, however, was not practically possible in our study due to the design of the experiment and the amount of biomass available. Therefore, the sulfuric acid method was chosen to allow comparison of all sugars in the biomasses generated within the study.

The iduronic acid content was not above 1 g (100 g)−1 in any of the experiments and most likely further optimization is needed before there is an economic case for extracting it. However, it is an interesting sugar, and if separated with the same recovery method as for rhamnose, it is a potential side product. According to the results in this study, irradiance and temperature are important factors for the optimization of iduronic acid content with a 70% increase in iduronic acid at elevated levels. Elevated nitrate had a negative effect on both rhamnose and iduronic acid contents, and it makes sense that they can be co-optimized as they are both part of ulvan. Another factor influencing the carbohydrate production capacity is biomass formation during cultivation. However, these data for our study will be reported elsewhere (Toth et al., manuscript pending revision), but in short higher irradiance, lower temperature, elevated phosphate, and ambient nitrate levels increased the growth rate. Thus, the total production will be further improved at high irradiation, where more biomass with a higher content of iduronic acid is produced.

Despite not being analysed directly due to limitations in available material, there are some interesting signs of changes to ulvan when U. fenestrata was grown under different conditions. Such structural differences of ulvan give a potential to compare bioactivities of ulvans of different composition from the same species and potentially tailor bioactivities already at the cultivation stage. It is known that the iduronic acid residues in glucosaminoglycans are important for their bioactivity due to their conformational flexibility allowing easier accessibility to the proteins targeted for the anticoagulant effect (Mohamed and Ferro 2015). Therefore, the quota between the iduronic acid and rhamnose (as the main monomer of the repeating disaccharide of ulvan) is an interesting indication of changed functionality of the ulvan polysaccharides. It is known that the functionality of ulvan changes depending on the extraction method used (Kidgell et al. 2019), which in turn can cause changes in its composition or structure. Hence, it is likely that any changes seen in the quota between rhamnose and iduronic acid would do so as well. How such changes caused by cultivation conditions relate to bioactivity needs to be further investigated, which was not possible within this study. A higher ratio means that there is more iduronic acid in the ulvan, which could be important for using Ulva spp. for extraction of iduronic acid as well as the bioactive compounds.

It is known that many of the activities of ulvan are similar to those of heparin, but a study on ulvan from U. rigida found it to be inactive against the anti-thrombin pathway unless chemically sulfated (Adrien et al. 2019). Heparin is mostly extracted from porcine mucosa at yields of 160–260 mg kg−1 (van der Meer et al. 2017), which is several times lower than the levels of iduronic acid seen here and much lower than the ulvan content in U. fenestrata, which contains at least 18% dw of ulvan (Wahlström et al. 2020). In a broad range of studies on U. lactuca, even higher ulvan contents up to 36% dw have been seen (Kidgell et al. 2019). If the changes observed in this study could be used to improve the activity of ulvan to levels where it can replace heparin, it can replace the offal of a billion pigs currently used in the production process (van der Meer et al. 2017). This could not only be advantageous from an environmental standpoint, but it is also safer for medicinal use as there is less risk of infectious diseases as well as prions to be in the product. However, further investigations into how growth conditions influence ulvan structure as well as the exact mechanisms for the biological activities of ulvan are needed before ulvan goes from a potential high-value product to become the basis of an industry based on its extraction and modification. Should replacement of current products not be possible, the utilization of building blocks from ulvan, i.e., iduronic acid, can still be utilized for chemical synthesis of glucosaminoglycans (e.g., heparin), rhamnolipids, or flavoring compounds.

Conclusion

Biomolecules from Ulva spp. have the potential to provide a variety of products to future society. In this study, we show the effects of temperature, irradiance, pCO2, nitrogen, and phosphate on the monosaccharide composition in Ulva fenestrata. The monosaccharides present in the potential high-value component ulvan changed significantly with higher fractions of iduronic acid at intermediate irradiance and ambient nitrate conditions, indicating changes to the polysaccharide. Also, there were signs of changes in the degree of sulfation at different temperature, and nutrient levels. These changes might be used to alter the biological activities of ulvan already at the cultivation stage, but this needs further investigation of the actual ulvan. The total amount of carbohydrates was significantly affected by temperature, nitrogen level, and pCO2, but more interestingly, the levels of some individual monosaccharides changed drastically with changed conditions. Rhamnose and iduronic acid content increased by 26 and 70% respectively at elevated temperature and irradiance. Testing other cultivation conditions than in this study, as well as including other environmental factors such as salinity could also add new knowledge important for finding the optimal cultivation conditions for U. fenestrata.

References

Abd-Ellatef GEF, Ahmed OM, Abdel-Reheim ES, Abdel-Hamid AHZ (2017) Ulva lactuca polysaccharides prevent Wistar rat breast carcinogenesis through the augmentation of apoptosis, enhancement of antioxidant defense system, and suppression of inflammation. Breast Cancer-Targets Ther 9:67–83

Adrien A, Bonnet A, Dufour D, Baudouin S, Maugard T, Bridiau N (2019) Anticoagulant activity of sulfated ulvan isolated from the green macroalga Ulva rigida. Mar Drugs 17:291

Bikker P, van Krimpen MM, van Wikselaar P, Houweling-Tan B, Scaccia N, van Hal JW, Huijgen WJJ, Cone JW, Lopez-Contreras AM (2016) Biorefinery of the green seaweed Ulva lactuca to produce animal feed, chemicals and biofuels. J Appl Phycol 28:3511–3525

Castro R, Piazzon MC, Zarra I, Leiro J, Noya M, Lamas J (2006) Stimulation of turbot phagocytes by Ulva rigida C. Agardh polysaccharides. Aquaculture 254:9–20

Chen B, Lin L, Ma Z, Zhang T, Chen W, Zou D (2019) Carbon and nitrogen accumulation and interspecific competition in two algae species, Pyropia haitanensis and Ulva lactuca, under ocean acidification conditions. Aquacult Int 27:721–733

De Ruiter GA, Schols HA, Voragen AGJ, Rombouts FM (1992) Carbohydrate analysis of water-soluble uronic acid-containing polysaccharides with high-performance anion-exchange chromatography using methanolysis combined with TFA hydrolysis is superior to four other methods. Anal Biochem 207:176–185

Esko JD, Selleck SB (2002) Order out of chaos: assembly of ligand binding sites in heparan sulfate. Annu Rev Biochem 71:435–471

Gao G, Clare AS, Rose C, Caldwell GS (2017) Eutrophication and warming-driven green tides (Ulva rigida) are predicted to increase under future climate change scenarios. Mar Pollut Bull 114:439–447

Gao G, Clare AS, Rose C, Caldwell GS (2018) Ulva rigida in the future ocean: potential for carbon capture, bioremediation and biomethane production. GCB Bioenergy 10:39–51

Golberg A, Zollmann M, Prabhu M, Palatnik RR (2020) Enabling bioeconomy with offshore macroalgae biorefineries. In: Keswani C (ed) Bioeconomy for sustainable development. Springer, Singapore, pp 173–200

Gómez Pinchetti JL, del Campo FE, Moreno Díez P, Reina GG (1998) Nitrogen availability influences the biochemical composition and photosynthesis of tank-cultivated Ulva rigida (Chlorophyta). J Appl Phycol 10:383–389

Hafting JT, Craigie JS, Stengel DB, Loureiro RR, Buschmann AH, Yarish C, Edwards MD, Critchley AT (2015) Prospects and challenges for industrial production of seaweed bioactives. J Phycol 51:821–837

He Y, Hu C, Wang Y, Cui D, Sun X, Li Y, Xu N (2018) The metabolic survival strategy of marine macroalga Ulva prolifera under temperature stress. J Appl Phycol 30:3611–3621

Holdt SL, Kraan S (2011) Bioactive compounds in seaweed: functional food applications and legislation. J Appl Phycol 23:543–597

Hughey JR, Maggs CA, Mineur F, Jarvis C, Miller KA, Shabaka SH, Gabrielson PW (2019) Genetic analysis of the Linnaean Ulva lactuca (Ulvales, Chlorophyta) holotype and related type specimens reveals name misapplications, unexpected origins, and new synonymies. J Phycol 55:503–508

Hussein UK, Mahmoud HM, Farrag AG, Bishayee A (2015) Chemoprevention of diethylnitrosamine-initiated and phenobarbital-promoted hepatocarcinogenesis in rats by sulfated polysaccharides and aqueous extract of Ulva lactuca. Integr Cancer Ther 14:525–545

Kaeffer B, Benard C, Lahaye M, Blottiere HM, Cherbut C (1999) Biological properties of ulvan, a new source of green seaweed sulfated polysaccharides, on cultured normal and cancerous colonic epithelial tells. Planta Med 65:527–531

Kidgell JT, Magnusson M, de Nys R, Glasson CRK (2019) Ulvan: a systematic review of extraction, composition and function. Algal Res 39:101422

Kim JK, Cho ML, Karnjanapratum S, Shin IS, You SG (2011) In vitro and in vivo immunomodulatory activity of sulfated polysaccharides from Enteromorpha prolifera. Int J Biol Macromol 49:1051–1058

Konda NVSN, Singh S, Simmons BA, Klein-Marcuschamer D (2015) An investigation on the economic feasibility of macroalgae as a potential feedstock for biorefineries. BioEnergy Res 8:1046–1056

Kumari P, Kumar M, Reddy CRK, Jha B (2014) Nitrate and phosphate regimes induced lipidomic and biochemical changes in the intertidal macroalga Ulva lactuca (Ulvophyceae, Chlorophyta). Plant Cell Physiol 55:52–63

Lahaye M, Robic A (2007) Structure and functional properties of ulvan, a polysaccharide from green seaweeds. Biomacromolecules 8:1765–1774

Leiro JM, Castro R, Arranz JA, Lamas J (2007) Immunomodulating activities of acidic sulphated polysaccharides obtained from the seaweed Ulva rigida C. Agardh Int Immunopharmacol 7:879–888

Mao WJ, Zang XX, Li Y, Zhang HJ (2006) Sulfated polysaccharides from marine green algae Ulva conglobata and their anticoagulant activity. J Appl Phycol 18:9–14

Mohamed S, Ferro V (2015) Synthetic approaches to l-Iduronic acid and l-Idose: key building blocks for the preparation of glycosaminoglycan oligosaccharides. In: Baker DC, Horton D (eds) Advances in carbohydrate chemistry and biochemistry, vol 72. Academic Press, New York, pp 21–61

Mohsen AF, Nasr AH, Metwalli AM (1973a) Effect of different light intensities on growth, reproduction, amino acid synthesis, fat and sugar contents in Ulva fasciata Delile. Hydrobiologia 43:125–135

Mohsen AF, Nasr AH, Metwalli AM (1973b) Effect of temperature variation on growth, reproduction, amino-acid synthesis, fat and sugar content in Ulva fasciata Delile plants. Hydrobiologia 42:451–460

Muller MM, Kugler JH, Henkel M, Gerlitzki M, Hormann B, Pohnlein M, Syldatk C, Hausmann R (2012) Rhamnolipids-next generation surfactants? J Biotech 162:366–380

Palatnik RR, Zilberman D (2017) Economics of natural resource utilization - the case of macroalgae. In: Pinto AA, Zilberman D (eds) Modeling, dynamics, optimization and bioeconomics II, DGS 2014. Springer, Cham, pp 1–21

Qi HM, Zhang QB, Zhao TT, Chen R, Zhang H, Niu XZ, Li Z (2005a) Antioxidant activity of different sulfate content derivatives of polysaccharide extracted from Ulva pertusa (Chlorophyta) in vitro. Int J Biol Macromol 37:195–199

Qi HM, Zhao TT, Zhang QB, Li Z, Zhao ZQ, Xing R (2005b) Antioxidant activity of different molecular weight sulfated polysaccharides from Ulva pertusa Kjellm (Chlorophyta). J Appl Phycol 17:527–534

Rabenstein DL (2002) Heparin and heparan sulfate: structure and function. Nat Prod Rep 19:312–331

Smetacek V, Zingone A (2013) Green and golden seaweed tides on the rise. Nature 504:84–88

Steinhagen S, Karez R, Weinberger F (2019) Cryptic, alien and lost species: molecular diversity of Ulva sensu lato along the German coasts of the north and Baltic seas. Eur J Phycol 54:466–483

Tabarsa M, Han JH, Kim CY, You SG (2012) Molecular characteristics and Immunomodulatory activities of water-soluble sulfated polysaccharides from Ulva pertusa. J Med Food 15:135–144

van der Meer JY, Kellenbach E, van den Bos LJ (2017) From farm to pharma: an overview of industrial heparin manufacturing methods. Molecules 22:13

van Wychen S, Laurens LML (2015) Determination of total carbohydrates in algal biomass laboratory analytical procedure (LAP). Denver, Colorado. Report NREL/TP-5100-60957, pp 1–14

Vilg JV, Nylund GM, Werner T, Qvirist L, Mayers JJ, Pavia H, Undeland I, Albers E (2015) Seasonal and spatial variation in biochemical composition of Saccharina latissima during a potential harvesting season for Western Sweden. Bot Mar 58:435–447

Wahlström N, Nylander F, Malmhäll-Bah E, Sjövold K, Edlund U, Westman G, Albers E (2020) Composition and structure of cell wall ulvans recovered from Ulva spp. along the Swedish west coast. Carbohydr Polym 233:115852

Wang QH, Dong SL, Tian XL, Wang F (2007) Effects of circadian rhythms of fluctuating temperature on growth and biochemical composition of Ulva pertusa. Hydrobiologia 586:313–319

Acknowledgements

Open access funding provided by Chalmers University of Technology.

Funding

The Swedish Foundation for Strategic Research (SSF), project number RBP14-0045, is acknowledged for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Olsson, J., Toth, G.B., Oerbekke, A. et al. Cultivation conditions affect the monosaccharide composition in Ulva fenestrata. J Appl Phycol 32, 3255–3263 (2020). https://doi.org/10.1007/s10811-020-02138-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-020-02138-9