Abstract

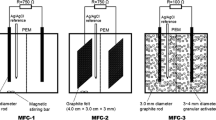

In microbial fuel cells, the surface areas of electrodes play a key role in power generation. Conventionally, the surface area ratio of 1 is considered, but it is neither electrochemically optimized nor economically justified. This study seeks the optimized ratio of Aan/Aca. in a double-chamber air-cathode pure-culture microbial fuel cell. Four different anode electrode surface areas were considered in four pure-culture air-cathode MFCs with the Aan/Aca. ratios of 0.4, 0.6, 0.8, and 1. Electrochemical impedance spectroscopy (EIS) indicates that as the Aan/Aca. ratio increases, total internal resistance decreases from 117.54 Ω to 42.03 Ω in which the share of substrate oxidation resistance ranges from 98% at the ratio of 0.4 to 86% at the ratio of 1. Tafel plot also indicates that exchange current increases from 3.76 mA to 19.27 mA as the anode surface increases suggesting higher reaction rates at higher ratios. The polarization test demonstrates that power output does not follow total resistance pattern and that maximum power density (based on the cathode surface) of 41.67 ± 2.08 mW.m−2 occurs at the Aan/Aca. ratio of 0.6. Also, the highest operating current of 1.17 mA is recorded at the Aan/Aca. ratio of 0.6 after 90 days of operation. These observations suggest that there is an optimum Aan/Aca. ratio of 0.6 in which the charge transfer rate is maximum and substrate oxidation rate is minimum. The results also suggest that there is a correlation between power output and Aan/Aca. ratio that predicts the optimum ratio of 0.68 where power output is maximum.

Graphical Abstract

Similar content being viewed by others

Data availability

The data used in this study are available upon reasonable request from the corresponding author.

References

Jatoi AS, Akhter F, Mazari SA, Sabzoi N, Aziz S, Soomro SA, Mubarak NM, Baloch H, Memon AQ, Ahmed S (2021) Advanced microbial fuel cell for waste water treatment—a review. Environ Sci Pollut Res 28:5005–5019. https://doi.org/10.1007/s11356-020-11691-2

Pandit C, Thapa BS, Srivastava B, Mathuriya AS, Toor UA, Pant M, Pandit S, Jadhav DA (2022) Integrating human waste with microbial fuel cells to elevate the production of bioenergy. BioTech 11:36. https://doi.org/10.3390/biotech11030036

Aboelela D, Soliman MA (2022) Hydrogen production from microbial electrolysis cells with microbial fuel cells. J King Saud Uni- Eng Sci. https://doi.org/10.1016/j.jksues.2022.05.008

Chen Z, Zhang S, Zhong L (2019) Simultaneous sulfide removal, nitrogen removal, and electricity generation in a coupled microbial fuel cell system. Bioresource Technol 291:121888. https://doi.org/10.1016/j.biortech.2019.121888

Cui Y, Lai B, Tang X (2019) Microbial fuel cell-based biosensors. Biosensors 9:92. https://doi.org/10.3390/bios9030092

Hassan H, Dai S, Jin B (2019) Bioelectrochemical reaction kinetics, mechanisms, and pathways of Chlorophenol degradation in MFC using different microbial consortia. ACS Sustainable Chemistry and Engineering 7(20):17263–17272. https://doi.org/10.1021/acssuschemeng.9b04038

Gurung A, Sen Thapa B, Ko S-Y, Ashun E, Ali Toor U, Oh S-E (2023) Denitrification in microbial fuel cells using granular activated carbon as an effective biocathode. Energies 16(2):709. https://doi.org/10.3390/en16020709

Fan X, Zhou Y, Jin X, Song R-B, Li X, Zhang Q (2021) Carbon material-based anodes in the microbial fuel cells. Carbon Energy 3(3):449–472. https://doi.org/10.1002/cey2.113

Rossi R, Evans PJ, Logan BE (2019) Impact of flow recirculation and anode dimensions on performance of a large scale microbial fuel cell. J Power Sources 412:294–300. https://doi.org/10.1016/j.jpowsour.2018.11.054

Asensio Y, Fernandez-Marchante CM, Lobato J, Cañizares P, Rodrigo MA (2018) Influence of the ion-exchange membrane on the performance of double-compartment microbial fuel cells. J Electroanal Chem 808:427–432. https://doi.org/10.1016/j.jelechem.2017.06.018

Yin T, Zhang H, Yang G, Wang L (2019) Polyaniline composite TiO2 nanosheets modified carbon paper electrode as a high performance bioanode for microbial fuel cells. Synth Met 252:8–14. https://doi.org/10.1016/j.synthmet.2019.03.027

Song X, Jo C, Han L, Zhou M (2022) Recent advance in microbial fuel cell reactor configuration and coupling technologies for removal of antibiotic pollutants. Curr Opin Electrochem 31:100833. https://doi.org/10.1016/j.coelec.2021.100833

Oh S-E, Logan BE (2006) Proton exchange membrane and electrode surface areas as factors that affect power generation in microbial fuel cells. Appl Microbiol Biotechnol 70:162–169. https://doi.org/10.1007/s00253-005-0066-y

Santoro C, Arbizzani C, Erable B, Ieropoulos I (2017) Microbial fuel cells: from fundamentals to applications. A review. J Power Sources 356:225–244. https://doi.org/10.1016/j.jpowsour.2017.03.109

Liu H, Logan BE (2004) Electricity generation using an air-cathode single chamber microbial fuel cell in the presence and absence of a proton exchange membrane. Environ Sci Technol 38:4040–4046. https://doi.org/10.1021/es0499344

Dentel S, Strogen B, Chiu P (2004) Direct generation of electricity from sludges and other liquid wastes. Water Sci Technol 50:161–168. https://doi.org/10.2166/wst.2004.0561

Gajda I, Stinchcombe A, Merino-Jimenez I, Pasternak G, Sanchez-Herranz D, Greenman J, Ieropoulos IA (2018) Miniaturized ceramic-based microbial fuel cell for efficient power generation from urine and stack development. Front Energy Res 6:84. https://doi.org/10.3389/fenrg.2018.00084

Pamintuan KRS, Bagumba IHV, Domingo ZDG (2020) Compartmentalization studies of a deep-design batch microbial fuel cell assembly. J Phys: Conf Ser 1457:012010. https://doi.org/10.1088/1742-6596/1457/1/012010

Hsu L, Chadwick B, Kagan J, Thacher R, Wotawa-Bergen A, Richter K (2013) Scale up considerations for sediment microbial fuel cells. RSC Adv 3:15947–15954. https://doi.org/10.1039/C3RA43180K

Li L, Kong X, Sun Y, Yuan Z, Li Y (2011) Performance of microbial fuel cell in different anode and cathode electrode sizes. International Conference on Remote Sensing. Environ Transp Eng:7707–7710. https://doi.org/10.1109/RSETE.2011.5966161

Ueoka N, Sese N, Sue M, Kouzuma A, Watanabe K (2016) Sizes of anode and cathode affect electricity generation in rice paddy-field microbial fuel cells. J Sustainable Bioenergy Systems 6:10. https://doi.org/10.4236/jsbs.2016.61002

Houghton J, Santoro C, Soavi F, Serov A, Ieropoulos I, Arbizzani C, Atanassov P (2016) Supercapacitive microbial fuel cell: characterization and analysis for improved charge storage/delivery performance. Bioresource Technol 218:552–560. https://doi.org/10.1016/j.biortech.2016.06.105

Papillon J, Ondel O, Maire E (2021) Scale up of single-chamber microbial fuel cells with stainless steel 3D anode: Effect of electrode surface areas and electrode spacing. Bioresource Technol Rep 13:100632. https://doi.org/10.1016/j.biteb.2021.100632

Watson VJ, Logan BE (2010) Power production in MFCs inoculated with Shewanella oneidensis MR-1 or mixed cultures. Biotechnol Bioeng 105:489–498. https://doi.org/10.1002/bit.22556

Macdonald JR (2018). In: Barsoukov E (ed) Impedance spectroscopy: theory, experiment, and applications, 3rd edn. Wiley, New York. https://doi.org/10.1002/9781119381860

Logan BE, Hamelers B, Rozendal R, Schröder U, Keller J, Freguia S, Aelterman P, Verstraete W, Rabaey K (2006) Microbial fuel cells: methodology and technology. Environ Sci Technol 40:5181–5192. https://doi.org/10.1021/es0605016

Lowy DA, Tender LM, Zeikus JG, Park DH, Lovley DR (2006) Harvesting energy from the marine sediment–water interface II: kinetic activity of anode materials. Biosens Bioelectron 21:2058–2063. https://doi.org/10.1016/j.bios.2006.01.033

Von Canstein H, Ogawa J, Shimizu S, Lloyd JR (2008) Secretion of flavins by Shewanella species and their role in extracellular electron transfer. Appl Environ Microbiol 74:615–623. https://doi.org/10.1128/AEM.01387-07

Ramasamy RP, Gadhamshetty V, Nadeau LJ, Johnson GR (2009) Impedance spectroscopy as a tool for non-intrusive detection of extracellular mediators in microbial fuel cells. Biotechnol Bioeng 104:882–891. https://doi.org/10.1002/bit.22469

Sonawane JM, Patil SA, Ghosh PC, Adeloju SB (2018) Low-cost stainless-steel wool anodes modified with polyaniline and polypyrrole for high-performance microbial fuel cells. J Power Sources 379:103–114. https://doi.org/10.1016/j.jpowsour.2018.01.001

Ha PT, Moon H, Kim BH, Ng HY, Chang IS (2010) Determination of charge transfer resistance and capacitance of microbial fuel cell through a transient response analysis of cell voltage. Biosens Bioelectron 25:1629–1634. https://doi.org/10.1016/j.bios.2009.11.023

Li M, Li Y-W, Cai Q-Y, Zhou S-Q, Mo C-H (2020) Spraying carbon powder derived from mango wood biomass as high-performance anode in bio-electrochemical system. Bioresour Technol 300:122623. https://doi.org/10.1016/j.biortech.2019.122623

Yang Y, Yan L, Song J, Xu M (2018) Optimizing the electrode surface area of sediment microbial fuel cells. RSC Adv 8:25139. https://doi.org/10.1039/C8RA05069D

Sun J, Li Y, Hu Y, Hou B, Xu Q, Zhang Y, Li S (2012) Enlargement of anode for enhanced simultaneous azo dye decolorization and power output in air-cathode microbial fuel cell. Biotechnol Lett 34:2023–2029. https://doi.org/10.1007/s10529-012-1002-8

Uría N, Sánchez D, Mas R, Sánchez O, Muñoz FX, Mas J (2012) Effect of the cathode/anode ratio and the choice of cathode catalyst on the performance of microbial fuel cell transducers for the determination of microbial activity. Sens Actuators B 170:88–94. https://doi.org/10.1016/j.snb.2011.02.030

Sadeqzadeh M, Ghasemi M, Ghannadzadeh A, Salamatinia B, Jafary T, Wan Daud WR, Aly Hassan SH (2012) Mass transfer limitation in different anode electrode surface areas on the performance of dual chamber microbial fuel cell. Am J Biochem Biotechnol 8:320–325. https://doi.org/10.3844/ajbbsp.2012.320.325

Matsena MT, Mabuse M, Tichapondwa SM, Chirwa EMN (2021) Improved performance and cost efficiency by surface area optimization of granular activated carbon in air-cathode microbial fuel cell. Chemosphere. https://doi.org/10.1016/j.chemosphere.2021.130941

Gurjar R, Behera M (2022) Bio-electrochemical performance of a ceramic microbial fuel cell treating kitchen waste leachate: effect of organic loading rate and anode electrode surface area. Fermentation 8:544. https://doi.org/10.3390/fermentation8100544

He Z, Kan J, Mansfeld F, Angenent LT, Nealson KH (2009) Self-sustained phototrophic microbial fuel cells based on the synergistic cooperation between photosynthetic microorganisms and heterotrophic bacteria. Environ Sci Technol 43:1648–1654. https://doi.org/10.1021/es803084a

Sekar N, Ramasamy RP (2013) Electrochemical impedance spectroscopy for microbial fuel cell characterization. J Microb Biochem Technol 6(2):1–14. https://doi.org/10.4172/1948-5948.S6-004

Baek G, Kim K-Y, Logan BE (2021) Impact of surface area and current generation on microbial electrolysis cell electrodes inserted into anaerobic digesters. Chemical Eng J. https://doi.org/10.1016/j.cej.2021.131281

Wei J, Liang P, Huang X (2011) Recent progress in electrodes for microbial fuel cells. Bioresour Technol 102:9335–9344. https://doi.org/10.1016/j.biortech.2011.07.019

Chen J, Zhao K, Wu Y, Liu J, Wang R, Yang y, Liu Y (2023) Improved bioelectrochemical performance of MnO2 nanorods modified cathode in microbial fuel cell. Environ Sci Pollut Res 30:49052–49059. https://doi.org/10.1007/s11356-023-25787-y

Ahmadian Yazdi A, D’Angelo L, Omer N, Windiasti G, Lu X, Xu J (2016) Carbon nanotube modification of microbial fuel cell electrodes. Biosens Bioelectron 85:536–552. https://doi.org/10.1016/j.bios.2016.05.033

Acknowledgments

The sponsor had no involvement in any of the following: study design; collection, analysis, and interpretation of data; writing the manuscript; or the submission decision. The authors are thankful to the Corrosion Research Laboratory for conducting part of the analyses.

Funding

This work was supported by Ferdowsi University of Mashhad, Graduate Students Research Fund, Grant No. 3/20573.

Author information

Authors and Affiliations

Contributions

HGM conducted the experiments; MAM designed and supervised the study and wrote the manuscript; RG conducted the statistical analysis of the data; MD assisted in manuscript writing and structure. All authors approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moradi, H.G., Mahdavi, M.A., Gheshlaghi, R. et al. Electrochemical evaluation of the effect of anode to cathode surface area ratio on power generation in air-cathode microbial fuel cells. J Appl Electrochem 53, 2433–2442 (2023). https://doi.org/10.1007/s10800-023-01929-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-023-01929-5