Abstract

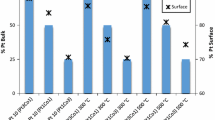

Deposition of platinum catalysts on a titanium substrate (Pt/Ti) was performed using various electrodeposition techniques, and an optimum deposition condition attributing to enhanced activity towards methanol oxidation reaction (MOR) was identified. Physical characterization confirmed that the variation of deposition parameters resulted in Pt nanostructures with various morphologies. The final morphology of the Pt catalyst was strongly influenced by the average potential applied or observed during the deposition. Dynamic applied waveform electrodeposition techniques, namely cyclic voltammetry deposition and pulse current deposition, were found to offer efficient deposition and homogeneous distribution of Pt on Ti compared to constant applied waveform deposition techniques such as potentiostatic and galvanostatic deposition, which could be attributed to the improved homogeneity of metal ion concentration during deposition. Among the various deposition techniques and parameters studied, results indicate that Pt catalysts deposited by pulse electrodeposition with a low-duty cycle was found to be the optimum to achieve high catalytic activity towards MOR. The results of this study not only reflect the fundamental understanding of Pt morphology at different deposition modes but also highlight the importance of performing the deposition with an optimal deposition technique and parameters to have a better and more efficient metal deposition from its precursor.

Graphic abstract

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information file.

References

Aricò AS, Srinivasan S, Antonucci V (2001) DMFCs: from fundamental aspects to technology development. Fuel Cells 1:133–161. https://doi.org/10.1002/1615-6854(200107)1:2%3c133::AID-FUCE133%3e3.3.CO;2-X

Larminie J, Dicks A (2003) Direct methanol fuel cells. Fuel Cell Syst Explain. https://doi.org/10.1002/9781118878330.ch6

Zheng J, Cullen DA, Forest RV et al (2015) Platinum-ruthenium nanotubes and platinum-ruthenium coated copper nanowires as efficient catalysts for electro-oxidation of methanol. ACS Catal 5:1468–1474. https://doi.org/10.1021/cs501449y

Tiwari JN, Tiwari RN, Singh G, Kim KS (2013) Recent progress in the development of anode and cathode catalysts for direct methanol fuel cells. Nano Energy 2:553–578. https://doi.org/10.1016/j.nanoen.2013.06.009

Liu H, Song C, Zhang L et al (2006) A review of anode catalysis in the direct methanol fuel cell. J Power Sources 155:95–110. https://doi.org/10.1016/j.jpowsour.2006.01.030

Abraham BG, Bhaskaran R, Chetty R (2020) Electrodeposited bimetallic (PtPd, PtRu, PtSn) catalysts on titanium support for methanol oxidation in direct methanol fuel cells. J Electrochem Soc 167:24512. https://doi.org/10.1149/1945-7111/ab6a7d

Feng YY, Song GH, Zhang Q et al (2017) Catalytic performance of non-alloyed bimetallic PtAu electrocatalysts for methanol oxidation reaction. Int J Hydrogen Energy 42:30109–30118. https://doi.org/10.1016/j.ijhydene.2017.10.102

Rodríguez VI, Veizaga NS, de Miguel SR (2017) Effect of the preparation method on the electrocatalytic activity of Pt-Sn/nanotubes catalysts used in DMFC. J Electrochem Soc 164:F1524–F1533. https://doi.org/10.1149/2.1811713jes

Wang Y-J, Wilkinson DP, Zhang J (2011) Noncarbon support materials for polymer electrolyte membrane fuel cell electrocatalysts. Chem Rev 111:7625–7651. https://doi.org/10.1021/cr100060r

Antolini E (2009) Carbon supports for low-temperature fuel cell catalysts. Appl Catal B Environ 88:1–24. https://doi.org/10.1016/j.apcatb.2008.09.030

Georgieva J, Valova E, Mintsouli I et al (2015) Pt(Ni) electrocatalysts for methanol oxidation prepared by galvanic replacement on TiO2 and TiO2–C powder supports. J Electroanal Chem 754:65–74. https://doi.org/10.1016/j.jelechem.2015.07.001

Yi Q, Huang W, Zhang J et al (2008) Methanol oxidation on titanium-supported nano-scale Ni flakes. Catal Commun 9:2053–2058. https://doi.org/10.1016/j.catcom.2008.03.051

Hassan HB (2009) Electrodeposited Pt and Pt-Sn nanoparticles on Ti as anodes for direct methanol fuel cells. J Fuel Chem Technol 37:346–354. https://doi.org/10.1016/S1872-5813(09)60024-4

Feng L, Li K, Chang J et al (2015) Nanostructured PtRu/C catalyst promoted by CoP as an efficient and robust anode catalyst in direct methanol fuel cells. Nano Energy 15:462–469. https://doi.org/10.1016/j.nanoen.2015.05.007

Boxall DL, Lukehart CM (2001) Rapid synthesis of Pt or Pd/carbon nanocomposites using microwave irradiation. Chem Mater 13:806–810. https://doi.org/10.1021/cm000521l

Tang Z, Ng HY, Lin J et al (2010) Pt/CNT-based electrodes with high electrochemical activity and stability for proton exchange membrane fuel cells. J Electrochem Soc 157:B245. https://doi.org/10.1149/1.3266933

Paunovic M, Schlesinger M (2006) Fundamentals of electrochemical deposition. Wiley, Hoboken

Nasirpouri F (2017) Electrodeposition of nanostructured materials. Springer International Publishing, Cham

Xing L, Jia J, Wang Y et al (2010) Pt modified TiO2 nanotubes electrode: preparation and electrocatalytic application for methanol oxidation. Int J Hydrogen Energy 35:12169–12173. https://doi.org/10.1016/j.ijhydene.2010.07.162

Hu J, Lu X, Foord JS, Wang Q (2009) Electrochemical deposition of Pt nanoparticles on diamond substrates. Phys Status Solidi Appl Mater Sci 206:2057–2062. https://doi.org/10.1002/pssa.200982226

Cheng TT, Gyenge EL (2009) Novel catalyst-support interaction for direct formic acid fuel cell anodes: Pd electrodeposition on surface-modified graphite felt. J Appl Electrochem 39:1925–1938. https://doi.org/10.1007/s10800-009-9901-7

Frei M, Köhler C, Dietel L et al (2018) Pulsed electrodeposition of highly porous pt alloys for use in methanol, formic acid, and glucose fuel cells. ChemElectroChem 5:1013–1023. https://doi.org/10.1002/celc.201800035

Abdel Rahim MA, Hassan HB (2009) Titanium and platinum modified titanium electrodes as catalysts for methanol electro-oxidation. Thin Solid Films 517:3362–3369. https://doi.org/10.1016/j.tsf.2008.12.006

Arenas LF, de León CP, Boardman RP, Walsh FC (2017) Electrodeposition of platinum on titanium felt in a rectangular channel flow cell. J Electrochem Soc 164:D57–D66. https://doi.org/10.1149/2.0651702jes

Abraham BG, Maniam KK, Kuniyil A, Chetty R (2016) Electrocatalytic performance of palladium dendrites deposited on titania nanotubes for formic acid oxidation. Fuel Cells 16:656–661. https://doi.org/10.1002/fuce.201600023

Lu G, Zangari G (2005) Electrodeposition of platinum on highly oriented pyrolytic graphite. Part I: electrochemical characterization. J Phys Chem B 109:7998–8007. https://doi.org/10.1021/jp0407324

Coutanceau C, Rakotondrainibé AF, Lima A et al (2004) Preparation of Pt–Ru bimetallic anodes by galvanostatic pulse electrodeposition: characterization and application to the direct methanol fuel cell. J Appl Electrochem 34:61–66. https://doi.org/10.1023/B:JACH.0000005578.83646.3a

Chou HY, Yeh TK, Tsai CH (2014) Electrodeposited Pt and PtRu nanoparticles without hydrogen evolution reaction on mesoporous carbon for methanol oxidation. Int J Electrochem Sci 9:5763–5775

Ye F, Xu C, Liu G et al (2018) Effect of pulse electrodeposition parameters on electrocatalytic the activity of methanol oxidation and morphology of Pt/C catalyst for direct methanol fuel cells. Energy Convers Manage 160:85–92. https://doi.org/10.1016/j.enconman.2018.01.027

Muthukumar V, Chetty R (2017) Morphological transformation of electrodeposited Pt and its electrocatalytic activity towards direct formic acid fuel cells. J Appl Electrochem 47:735–745. https://doi.org/10.1007/s10800-017-1076-z

Scharifker BR (1999) On the theory of the potentiostatic current transient for diffusion-controlled three-dimensional electrocrystallization processes. J Electrochem Soc 146:1005. https://doi.org/10.1149/1.1391713

Simonov AN, Cherstiouk OV, Vassiliev SY et al (2014) Potentiostatic electrodeposition of Pt on GC and on HOPG at low loadings: analysis of the deposition transients and the structure of Pt deposits. Electrochim Acta 150:279–289. https://doi.org/10.1016/j.electacta.2014.10.098

Zhang H, Jiang F, Zhou R et al (2011) Effect of deposition potential on the structure and electrocatalytic behavior of Pt micro/nanoparticles. Int J Hydrogen Energy 36:15052–15059. https://doi.org/10.1016/j.ijhydene.2011.08.072

Maniam KK, Muthukumar V, Chetty R (2016) Electrodeposition of dendritic palladium nanostructures on carbon support for direct formic acid fuel cells. Int J Hydrogen Energy 41:18602–18609. https://doi.org/10.1016/j.ijhydene.2016.08.064

Maniam KK, Chetty R (2015) Electrochemical synthesis of palladium dendrites on carbon support and their enhanced electrocatalytic activity towards formic acid oxidation. J Appl Electrochem 45:953–962. https://doi.org/10.1007/s10800-015-0860-x

Bu L, Feng Y, Yao J et al (2016) Facet and dimensionality control of Pt nanostructures for efficient oxygen reduction and methanol oxidation electrocatalysts. Nano Res 9:2811–2821. https://doi.org/10.1007/s12274-016-1170-2

Hosseini MG, Momeni MM (2012) evaluation of the performance of platinum nanoparticle—titanium oxide nanotubes as a new refreshable electrode for formic acid. Electro-oxidation. https://doi.org/10.1002/fuce.201100173

Saminathan K, Kamavaram V, Veedu V, Kannan AM (2009) Preparation and evaluation of electrodeposited platinum nanoparticles on in situ carbon nanotubes grown carbon paper for proton exchange membrane fuel cells. Int J Hydrogen Energy 34:3838–3844. https://doi.org/10.1016/j.ijhydene.2009.03.009

Natter H, Hempelmann R (1996) Nanocrystalline copper by pulsed electrodeposition: the effects of organic additives, bath temperature, and pH. J Phys Chem 100:19525–19532. https://doi.org/10.1021/jp9617837

Zhang H, Zhou W, Du Y et al (2010) One-step electrodeposition of platinum nanoflowers and their high efficient catalytic activity for methanol electro-oxidation. Electrochem Commun 12:882–885. https://doi.org/10.1016/j.elecom.2010.04.011

Gollas B, Elliott JM, Bartlett PN (2000) Electrodeposition and properties of nanostructured platinum films studied by quartz crystal impedance measurements at 10 MHz. Electrochim Acta 45:3711–3724. https://doi.org/10.1016/S0013-4686(00)00464-3

Chung DY, Lee KJ, Sung YE (2016) Methanol electro-oxidation on the Pt surface: revisiting the cyclic voltammetry interpretation. J Phys Chem C 120:9028–9035. https://doi.org/10.1021/acs.jpcc.5b12303

Schmidt TJ (1998) Characterization of high-surface-area electrocatalysts using a rotating disk electrode configuration. J Electrochem Soc 145:2354. https://doi.org/10.1149/1.1838642

Chandrasekar MS, Pushpavanam M (2008) Pulse and pulse reverse plating—conceptual, advantages and applications. Electrochim Acta 53:3313–3322. https://doi.org/10.1016/j.electacta.2007.11.054

Landolt D, Marlot A (2003) Microstructure and composition of pulse-plated metals and alloys. Surf Coat Technol 169–170:8–13. https://doi.org/10.1016/S0257-8972(03)00042-2

Huang HX, Chen SX, Yuan C (2008) Platinum nanoparticles supported on activated carbon fiber as catalyst for methanol oxidation. J Power Sources 175:166–174. https://doi.org/10.1016/j.jpowsour.2007.08.107

Funding

This study was carried out with financial support from the Ministry of New and Renewable Energy (MNRE, Grant No. 102/61/2009-NT), Government of India.

Author information

Authors and Affiliations

Contributions

Both authors have contributed substantially to the conception and design of the study. BGA performed experiments, analysis, and interpretation. RC supervised the research. Both authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Abraham, B.G., Chetty, R. Influence of electrodeposition techniques and parameters towards the deposition of Pt electrocatalysts for methanol oxidation. J Appl Electrochem 51, 503–520 (2021). https://doi.org/10.1007/s10800-020-01510-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01510-4