Abstract

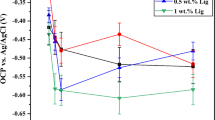

A nitrite intercalated layered double hydroxide (LDH-NO2) was suggested as an intelligent corrosion inhibitor to provide smart corrosion protection triggered by aggressive ions. A comparison of the inhibiting properties between NaNO2 and LDH-NO2 in the gradually contaminated concrete pore solution was investigated using electrochemical impedance spectroscopy, Mott–Schottky analysis and X-ray photoelectron spectroscopy. The results show that LDH-NO2 exhibits better long-term inhibition performance, and the aggressive ion thresholds for inducing corrosion are 0.1, 0.4, and 0.8 wt% in the blank, NaNO2, and LDH-NO2 solutions, respectively. The reason for this excellent inhibition efficiency is that nitrites can release in time and on demand from the LDH, preventing the corrosion nucleation and metastable pitting corrosion of steel reinforcement caused by chlorides.

Graphic abstract

LDH-NO2 exhibits better long-term inhibition performance when compared with NaNO2. The reason for this excellent inhibition efficiency is that nitrites can release in time and on demand from the LDH, preventing the corrosion nucleation and metastable pitting corrosion of steel reinforcement caused by chlorides.

Similar content being viewed by others

References

Hou BR, Li XG, Ma X et al (2017) The cost of corrosion in China. NPJ Mater Degrad 1:4

El-Reedy MA (2008) Steel-reinforced concrete structures. CRC Press, New York, pp 5–6

Anna KY, Jung HS, Kim HS et al (2006) Effect of calcium nitrite-based corrosion inhibitor in preventing corrosion of embedded steel in concrete. Cem Concr Res 36:530–535

Królikowskia A, Kuziak J (2011) Impedance study on calcium nitrite as a penetrating corrosion inhibitor for steel in concrete. Electrochim Acta 56:7845–7853

Reou JS, Ann KY (2008) The electrochemical assessment of corrosion inhibition effect of calcium nitrite in blended concretes. Mater Chem Phys 109:526–533

Zheludkevich ML, Tedim J, Ferreira MGS (2012) “Smart” coatings for active corrosion protection based on multi-functional micro and nanocontainers. Electrochim Acta 82:314–323

Mangadlao JD, Cao PF, Advincula RC (2015) Smart cements and cement additives for oil and gas operations. J Petrol Sci Eng 129:63–76

Tedim J, Kuznetsova A, Salak AN et al (2012) Zn-Al layered double hydroxides as chloride nanotraps in active protective coatings. Corros Sci 55:1–4

Tedim J, Zheludkevich ML, Bastos AC et al (2014) Influence of preparation conditions of layered double hydroxide conversion films on corrosion protection. Electrochim Acta 117:164–171

Imanieh I, Afshar A (2019) Corrosion protection of aluminum by smart coatings containing layered double hydroxide (LDH) nanocontainers. J Mater Res Technol 8:3004–3023

Xua JX, Song YB, Zhao YH et al (2018) Chloride removal and corrosion inhibitions of nitrate, nitrite-intercalated Mg-Al layered double hydroxides on steel in saturated calcium hydroxide solution. Appl Clay Sci 163:129–136

Yin HS, Cui L, Ai SY et al (2010) Electrochemical determination of bisphenol A at Mg–Al-CO3 layered double hydroxide modified glassy carbon electrode. Electrochim Acta 55:603–610

Hu JL, Gan MY, Ma L et al (2014) Synthesis and anticorrosive properties of polymer-clay nanocomposites via chemical grafting of polyaniline onto Zn-Al layered double hydroxides. Surf Coat Technol 240:55–62

Alibakhshi E, Ghasemi E, Mahdavian M et al (2017) Active corrosion protection of Mg-Al-PO43− LDH nanoparticle in silane primer coated with epoxy on mild steel. J Taiwan Inst Chem Eng 75:248–262

Alibakhshi E, Ghasemi E, Mahdavian M, Ramezanzadeh B (2017) A comparative study on corrosion inhibitive effect of nitrate and phosphate intercalated Zn-Al-layered double hydroxides (LDHs) nanocontainers incorporated into a hybrid silane layer and their effect on cathodic delamination of epoxy topcoat. Corros Sci 115:159–174

Alibakhshi E, Ghasemi E, Mahdavian M, Ramezanzadeh B (2017) Fabrication and characterization of layered double hydroxide/silane nanocomposite coatings for protection of mild steel. J Taiwan Inst Chem Eng 80:924–934

Alibakhshi E, Ghasemi E, Mahdavian M et al (2016) Fabrication and characterization of PO43− intercalated Zn-Al-layered double hydroxide nanocontainer. J Electrochem Soc 163:C495–C505

Yasakau KA, Kuznetsova A, Kallip S et al (2018) A novel bilayer system comprising LDH conversion layer and sol-gel coating for active corrosion protection of AA2024. Corros Sci 143:299–313

Tedim J, Bastos AC, Kallip S et al (2016) Corrosion protection of AA2024-T3 by LDH conversion films: analysis of SVET results. Electrochim Acta 210:215–224

Yasakau KA, Tedim J, Zheludkevich ML, Ferreira MGS (2014) Handbook of smart coatings for materials protection: smart self-healing coatings for corrosion protection of aluminium alloys. Elsevier, Amsterdam, pp 224–274

Anjuma MJ, Zhao JM, Asl VZ et al (In press) In-situ intercalation of 8-hydroxyquinoline in Mg-Al LDH coating to improve the corrosion resistance of AZ31. Corros Sci

Li J, Lin KD, Luo XH et al (2019) Enhanced corrosion protection property of Li-Al layered double hydroxides (LDHs) film modified by 2-guanidinosuccinic acid with excellent self-repairing and self-antibacterial properties. Appl Surf Sci 480:384–394

Bernal SA, San Nicolas R, Myers RJ et al (2014) MgO content of slag controls phase evolution and structural changes induced by accelerated carbonation in alkali-activated binders. Cem Concr Res 57:33–43

Machner A, Zajac M, Haha MB et al (2018) Chloride-binding capacity of hydrotalcite in cement pastes containing dolomite and metakaolin. Cem Concr Res 107:163–181

Ke XY, Bernal SA, Provis JL (2017) Uptake of chloride and carbonate by Mg-Al and Ca-Al layered double hydroxides in simulated pore solutions of alkali-activated slag cement. Cem Concr Res 100:1–13

Wu YY, Duan P, Yan CJ (2018) Role of layered double hydroxides in setting, hydration degree, microstructure and compressive strength of cement paste. Appl Clay Sci 158:12–131

Yang ZX, Polder R, Mole JMC, Andrade C (2017) The effect of two types of modified Mg-Al hydrotalcites on reinforcement corrosion in cement mortar. Cem Concr Res 100:186–202

Tian YW, Dong CF, Wang G et al (2019) Zn-Al-NO2 layered double hydroxide as a controlled-release corrosion inhibitor for steel reinforcements. Mater Lett 236:517–520

Chakri S, Frateur I, Orazem ME et al (2017) Improved EIS analysis of the electrochemical behaviour of carbon steel in alkaline solution. Electrochim Acta 246:924–930

Dong ZH, Shi W, Zhang GA, Guo XP (2011) The role of inhibitors on the repassivation of pitting corrosion of carbon steel in synthetic carbonated concrete pore solution. Electrochim Acta 56:5890–5897

Singh JK, Singh DDN (2012) The nature of rusts and corrosion characteristics of low alloy and plain carbon steels in three kinds of concrete pore solution with salinity and different pH. Corros Sci 56:129–142

Ghods P, Isgor OB, Bensebaa F, Kingston D (2012) Angle-resolved XPS study of carbon steel passivity and chloride-induced depassivation in simulated concrete pore solution. Corros Sci 58:159–167

Long Y, Li DG, Chen DR (2017) Influence of square wave anodization on the electronic properties and structures of the passive films on Ti in sulfuric acid solution. Appl Surf Sci 425:83–94

Li TS, Liu L, Zhang B et al (2016) An investigation on the continuous and uniform thin membrane passive film formed on sputtered nanocrystalline stainless steel. Corros Sci 104:71–83

Yao JZ, Macdonald DD, Dong CF (2019) Passive film on 2205 duplex stainless steel studied by photo-electrochemistry and ARXPS methods. Corros Sci 146:221–232

Oh KN, Ahn SH, Eom KS et al (2014) Observation of passive films on Fe-20Cr-xNi (x=0, 10, 20 wt.%) alloys using TEM and Cs-corrected STEM-EELS. Corros Sci 79:34–40

Gabrielli C, Joiret S, Keddam M et al (2007) A SECM assisted EQCM study of iron pitting. Electrochim Acta 52:7706–7714

Kunze J, Maurice V, Klein LH et al (2004) In situ STM study of the duplex passive films formed on Cu(111) and Cu(001) in 0.1 M NaOH. Corros Sci 46:245–264

Zheng HB, Dai JG, Poon CS, Li WH (2018) Influence of calcium ion in concrete pore solution on the passivation of galvanized steel bars. Cem Concr Res 108:46–58

Poursaee A, Hansson CM (2007) Reinforcing steel passivation in mortar and pore solution. Cem Concr Res 37:11–27

Ghods P, Isgor OB, McRae G, Miller T (2009) The effect of concrete pore solution composition on the quality of passive oxide films on black steel reinforcement. Cement Concr Compos 31:2–11

Liu M, Cheng XQ, Li XG et al (2015) Corrosion behavior of Cr modified HRB400 steel rebar in simulated concrete pore solution. Constr Build Mater 93:884–890

Keddam M, Takenouti H, Nóvoa XR et al (1997) Impedance measurements on cement paste. Cem Concr Res 27:1191–1201

Poursaee A (2016) Temperature dependence of the formation of the passivation layer on carbon steel in high alkaline environment of concrete pore solution. Electrochem Commun 73:24–28

Williamson J, Isgor OB (2016) The effect of simulated concrete pore solution composition and chlorides on the electronic properties of passive films on carbon steel rebar. Corros Sci 106:82–95

Simoes A, Ferreira M, Rondot B, Belo M (1990) Study of passive films formed on AISI 304 stainless steel by impedance measurements and photoelectrochemistry. J Electrochem Soc 137:82–87

Gadala IM, Alfantazi A (2015) A study of X100 pipeline steel passivation in mildly alkaline bicarbonate solutions using electrochemical impedance spectroscopy under potentiodynamic conditions and Mott-Schottky. Appl Surf Sci 357:356–368

Harrington SP, Wang F, Devine TM (2010) The structure and electronic properties of passive and prepassive films of iron in borate buffer. Electrochim Acta 55:4092–4102

Luo H, Wang XZ, Dong CF et al (2017) Effect of cold deformation on the corrosion behaviour of UNS S31803 duplex stainless steel in simulated concrete pore solution. Corros Sci 124:178–192

Haleem SMAE, Aal EEAE, Wanees SAE, Diab A (2010) Environmental factors affecting the corrosion behaviour of reinforcing steel: I. The early stage of passive film formation in Ca(OH)2 solutions. Corros Sci 52:3875–3882

Fajardo S, Bastidas DM, Criado M, Bastidas JM (2014) Electrochemical study on the corrosion behavior of a new low-nickel stainless steel in carbonated alkaline solution in the presence of chlorides. Electrochim Acta 129:160–170

Feliu V, González JA, Andrade C, Feliu S (1998) Equivalent circuit for modelling the steel-concrete interface. I. experimental evidence and theoretical predictions. Corros Sci 40:975–993

Carmezim MJ, Simões AM, Figueiredo MO, Belo MDC (2002) Electrochemical behaviour of thermally treated Cr-oxide films deposited on stainless steel. Corros Sci 44:451–465

Cheng YF, Luo JL (1999) Electronic structure and pitting susceptibility of passive film on carbon steel. Electrochim Acta 44:2947–2957

Wang JL, Hou BS, Xiang J et al (2019) The performance and mechanism of bifunctional biocide sodium pyrithione against sulfate reducing bacteria in X80 carbon steel corrosion. Corros Sci 150:296–308

Subramanian H, Subramanian V, Chandramohan P et al (2015) Long-term survival of Desulfovibrio vulgaris on carbon steel and associated pitting corrosion. Corros Sci 90:89–100

Das IK, Pradhan B (2019) Effect of cation type of chloride salts on corrosion behaviour of steel inconcrete powder electrolyte solution in the presence of corrosion inhibitors. Constr Build Mater 208:175–191

Gunay HB, Ghods P, Isgor OB et al (2013) Characterization of atomic structure of oxide films on carbon steel in simulated concrete pore solutions using EELS. Appl Surf Sci 274:195–202

Abreu CM, Cristobal MJ, Losada R et al (2006) Long-term behaviour of AISI 304L passive layer in chloride containing medium. Electrochim Acta 51:1881–1890

Mahmoud H, Sánchez M, Alonso MC (2015) Ageing of the spontaneous passive state of 2304 duplex stainless steel in high-alkaline conditions with the presence of chloride. J Solid State Electrochem 19:2961–2972

Mohagheghi A, Arefinia R (2018) Corrosion inhibition of carbon steel by dipotassium hydrogen phosphatein alkaline solutions with low chloride contamination. Constr Build Mater 187:760–772

Liu R, Jiang LH, Xu JX et al (2014) Influence of carbonation on chloride-induced reinforcement corrosion in simulated concrete pore solutions. Constr Build Mater 56:16–20

Xu AN, Dong CF, Wei X et al (2019) DFT and photoelectrochemical studies of point defects in passive films on copper. J Electroanal Chem 834:216–222

Andrade C, Alonso C (1996) Corrosion rate monitoring in the laboratory and on-site. Constr Build Mater 10:315–328

Gaidis JM (2004) Chemistry of corrosion inhibitors. Cem Concr Compos 26:181–189

Lee DY, Kim WC, Kim JG (2012) Effect of nitrite concentration on the corrosion behaviour of carbon steel pipelinesin synthetic tap water. Corros Sci 64:105–114

Bloom MC, Goldenberg L (1965) γ-Fe2O3 and the passivity of iron. Corros Sci 5:623–630

Ngala VT, Page CL, Page MM (2002) Corrosion inhibitor systems for remedial treatment of reinforced concrete. Part 1: calcium nitrite. Corros Sci 44:2073–2208

Tian HC, Cheng XQ, Wang Y et al (2018) Effect of Mo on interaction between α/γ phases of duplex stainless steel. Electrochim Acta 167:255–268

Oguzie EE, Li JB, Liu YQ et al (2010) The effect of Cu addition on the electrochemical corrosion and passivation behavior of stainless steels. Electrochim Acta 55:5028–5035

Macdonald DD (2011) The history of the point defect model for the passive state: a brief review of film growth aspects. Electrochim Acta 56:1761–1772

Mantia FL, Habazaki H, Santamaria M, Quarto FD (2010) A critical assessment of the Mott-Schottky analysis for the characterisation of passive film-electrolyte junctions. Russ J Electrochem 46:1306–1322

Mantiaa FL, Fan M, Stojadinovic J et al (2015) Assessment on the use of the amorphous semiconductor theory for the analysis of oxide films. Electrochim Acta 179:460–468

Amri J, Souier T, Malki B, Baroux B (2008) Effect of the final annealing of cold rolled stainless steels sheets on the electronic properties and pit nucleation resistance of passive films. Corros Sci 50:431–435

Ogunsanya IG, Hansson CM (2019) The semiconductor properties of passive films and corrosion behavior of stainless steel reinforcing bars in simulated concrete pore solution. Materialia 6:100321–100334

Ries LAS, Belo MDC, Ferreira MGS, Muller IL (2008) Chemical composition and electronic structure of passive films formed on Alloy 600 in acidic solution. Corros Sci 50:676–686

Freire L, Carmezim MJ, Ferreira MGS, Montemor MF (2010) The passive behaviour of AISI 316 in alkaline media and the effect of pH: A combined electrochemical and analytical study. Electrochim Acta 55:6174–6181

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51801033).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tian, Y., Wen, C., Wang, G. et al. Inhibiting property of nitrite intercalated layered double hydroxide for steel reinforcement in contaminated concrete condition. J Appl Electrochem 50, 835–849 (2020). https://doi.org/10.1007/s10800-020-01439-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01439-8