Abstract

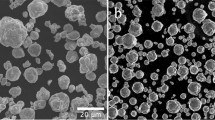

Pure and composite nickel deposits containing nano-TiO2 particles (d m = 21 nm) were produced under direct-DC and pulse current-PC conditions. The influence of pulse frequency on the codeposition of TiO2 particles, preferred orientation of Ni crystallites and grain size, as well as microhardness of the composites, was investigated systematically. Composites prepared in PC regime displayed higher incorporation percentage than those obtained under DC conditions, and the highest incorporation rates were achieved at pulse frequencies ν > 100 Hz. The application of pulse frequency accompanied by the embedding of TiO2 nanoparticles in the nickel matrix resulted in a strong influence upon the crystalline orientation, the grain size and the corresponding microhardness. All composites exhibited higher microhardness values compared to the pure deposits, independent of the applied current conditions. Overall, when ascribing the observed strengthening effect of composites, not only grain refinement and dispersion strengthening mechanisms but also preferred crystalline orientation should be taken into consideration.

Similar content being viewed by others

References

Viswanathan V, Laha T, Balani K, Agarwal A, Seal S (2006) Mater Sci Eng R 54:121

Ui K, Fujita T, Koura N, Yamaguchi F (2006) J Electrochem Soc 153:C449

De Tacconi NR, Carmona J, Rajeshwar K (2000) Langmuir 16:5665

Deguchi T, Imai K, Matsui H, Iwasaki M, Tada H, Ito S (2001) J Mater Sci 36:4723

Praveen BM, Venkatesha TV (2008) Appl Surf Sci 254:2418

Li J, Sun Y, Sun X, Qiao J (2005) Surf Coat Technol 192:331

Lin CS, Lee CY, Chang CF, Chang CH (2006) Surf Coat Technol 200:3690

Lampke Th, Leopold A, Dietrich D, Alisch G, Wielage B (2006) Surf Coat Technol 201:3510

Sun XJ, Li JG (2007) Tribol Lett 28:223

Abdel-Aal A (2008) Mater Sci Eng A 474:181

Thiemig D, Bund A (2008) Surf Coat Technol 202:2976

Wielage B, Lampke Th, Zacher M, Dietrich D (2008) Key Eng Mater 384:283

Abdel-Aal A, Hassan HB (2009) J Alloys Compd 477:652

Spanou S, Pavlatou EA, Spyrellis N (2009) Electrochim Acta 54:2547

Lampke Th, Wielage B, Dietrich D, Leopold A (2006) Appl Surf Sci 253:2399

Ibl N, Puippe JC, Angerer H (1978) Surf Technol 6:287

Kollia C, Spyrellis N, Amblard J, Froment M, Froment M, Maurin G (1990) J Appl Electrochem 20:1025

Choo RTC, Toguri JM, El-Sherik AM, Erb U (1995) J Appl Electrochem 25:384

Gyftou P, Pavlatou EA, Spyrellis N (2008) Appl Surf Sci 254:5910

Zimmerman AF, Clark DG, Aust KT, Erb U (2002) Mater Lett 52:85

Qu NS, Chan KC, Zhu D (2004) Scripta Mater 50:1131

Chen L, Wang L, Zeng Z, Xu T (2006) Surf Coat Technol 201:599

Wang W, Hou FY, Wang H, Guo HT (2005) Scripta Mater 53:613

Stroumbouli M, Gyftou P, Pavlatou EA, Spyrellis N (2005) Surf Coat Technol 195:325

Wang L, Gao Y, Xue Q, Liu H, Xu T (2005) Mater Sci Eng A 390:313

Pavlatou EA, Stroumbouli M, Gyftou P, Spyrellis N (2006) J Appl Electrochem 36:385

Kollia C, Patta C, Vassiliou P, Kasselouri V (2003) “CTM 2003”, 5–7 November 2003, Madrid, pp 417–428

Yang X, Li Q, Hu J, Zhong X, Zhang S (2009) J Appl Electrochem 40:39

Pavlatou EA, Raptakis M, Spyrellis N (2007) Surf Coat Technol 201:4571

Zanella C, Lekka M, Bonora PL (2009) J Appl Electrochem 39:31

Celis JP, Roos JR, Vooren WV, Vanhumbeeck J (1987) Oberflaeche Surf 6:16

Bahrololoom ME, Sani R (2005) Surf Coat Technol 192:154

Podlaha EJ, Landolt D (1997) J Electrochem Soc 144:L200

Celis JP, Roos JR, Buelens C (1987) J Electrochem Soc 134:1402

Celis JP, Roos JR (1977) J Electrochem Soc 124:1508

Tantavichet N, Pritzker M (2005) Electrochim Acta 50:1849

Amblard J, Froment M, Spyrellis N (1977) Surf Technol 5:205

Low CTJ, Wills RGA, Walsh FC (2006) Surf Coat Technol 201:371

Fritz T, Griepentrog M, Mokwa W, Schnakenberg U (2003) Electrochim Acta 48:3029

Hou F, Wang W, Guo H (2006) Appl Surf Sci 252:3812

Acknowledgements

The authors would like to dedicate this study to the memory of Professor Nicolas Spyrellis, who has greatly inspired them during this study. This paper is part of the 03ED963/2003 research project, implemented within the framework of the “Reinforcement Programme of Human Research Manpower” (PENED) and co-financed by National and Community Funds (20% from the Greek Ministry of Development-General Secretariat of Research and Technology and 80% from E.U.-European Social Fund).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spanou, S., Pavlatou, E.A. Pulse electrodeposition of Ni/nano-TiO2 composites: effect of pulse frequency on deposits properties. J Appl Electrochem 40, 1325–1336 (2010). https://doi.org/10.1007/s10800-010-0080-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-010-0080-3