Abstract

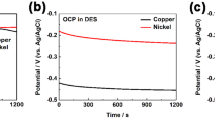

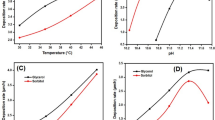

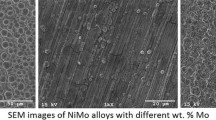

K4Fe(CN)6 was used to improve the microstructure and properties of copper deposits obtained from hypophosphite baths. In electroless copper plating solutions using hypophosphite as the reducing agent, nickel ions (0.0038 M with Ni2+/Cu2+ mole ratio 0.12) was used to catalyze hypophosphite oxidation. However, the color of the copper deposits was dark or brown and its resistivity was much higher than that obtained in formaldehyde baths. The effects of K4Fe(CN)6 on the deposit composition, resistivity, structure, morphology and the electrochemical reactions of hypophosphite (oxidation) and cupric ion (reduction) have been investigated. The deposition rate and the resistivity of the copper deposits decreased significantly with the addition of K4Fe(CN)6 to the plating solution and the color of the deposits changed from dark-brown to copper-bright with improved uniformity. The nickel and phosphorus content in the deposits also decreased slightly with the use of K4Fe(CN)6. Smaller crystallite size and higher (111) plane orientation were obtained by addition of K4Fe(CN)6. The electrochemical current–voltage results show that K4Fe(CN)6 inhibited the catalytic oxidation of hypophosphite at active nickel sites and reduced the reduction reaction of cupric ions on the deposit surface by adsorption on the electrode. This results in lower deposition rate and a decrease in the mole ratio of NaH2PO2/CuSO4 consumed during plating.

Similar content being viewed by others

References

Kou SC, Hung A (2003) Plat Surf Finish 90(3):44

Deckert CA (1995) Plat Surf Finish 82(2):48

Deckert CA (1995) Plat Surf Finish 82(2):58

Li J, Kohl PA (2003) J Electrochem Soc 150(8):C558

Cheng DH, Xu WY, Zhang ZY, Yiao ZH (1997) Met Finish 95(1):34

Rangarajan J, Mahadevaiyer K, Gregory W (1989) U.S. Pat. 4,818,286

Hung A, Ohno I (1990) J Electrochem Soc 137(3):918

Hung A, Chen KM (1989) J Electrochem Soc 136(1):72

Vaskelis A, Norkus E, Jaciauskiene J (2002) J Appl Electrochem 32:297

Li J, Kohl PA (2002) J Electrochem Soc 149(12):C631

Li J, Hayden H, Kohl PA (2004) Electrochim Acta 49:1789

Lin WH, Chang HF (1998) Surf Coat Technol 107:48

Vaskelis A, Jaciauskiene J, Stalnioniene I, Norkus E (2006) J Electroanal Chem 600(1):6

Cullity BD (1978) Elements of X-ray Diffraction. Addison-Wesley, London

Fierro JLF (1990) Spectroscopic characterization of heterogeneous catalysts, part: B. Elsevier, The Netherlands

Patterson JC, O’Reilly M, Crean GM, Barrett J (1997) Microelectron Eng 33:65

Tzeng SS, Chang FY (2001) Thin Solid Films 388:143

Ohno I, Wakabayashi O, Haruyama S (1985) J Electrochem Soc 132:2323

Paunovic M, Zeblisky R (1985) Plat Surf Finish 72(2):52

Hung A (1988) Plat Surf Finish 75(1):62

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gan, X., Wu, Y., Liu, L. et al. Effects of K4Fe(CN)6 on electroless copper plating using hypophosphite as reducing agent. J Appl Electrochem 37, 899–904 (2007). https://doi.org/10.1007/s10800-007-9327-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-007-9327-z