Abstract

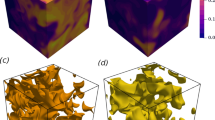

In this study, CFD modeling of a combustion system with internal gas circulation technology was carried out for a cylindrical chamber with 0.33 m height and a 0.025 m radius in which feed enters from a nozzle with 0.003 m diameter. The simulation implements the DRM-22 chemical mechanism, modified kє turbulence model, and EDC combustion model. The effect of chamber shape and diameter, nitrogen and carbon dioxide concentration of the input feed in MILD combustion was evaluated. The results indicated that by changing the combustion chamber shape from cylindrical to convergent, the temperature contour is more uniform and CO mass fraction at the output of the combustion chamber decreases. The maximum temperature for 901.4 Nml·min−1 methane and 9148 Nml·min−1 for divergent, cylindrical, and convergent cone chambers are 1820 K, 1663 K, and 1655 K, respectively. By increasing the radius of the combustion chamber, the temperature distribution becomes more uniform due to increasing the return flow, and the maximum temperature and CO emission at the chamber outlet decrease. By decreasing the nitrogen concentration on the input feed and increasing H2O and CO2 concentration, the temperature profile becomes more uniform so that the maximum temperature in the case without nitrogen (with 0.37 carbon dioxide and water vapor mass fraction) is 1510 K, while for a case with a 0.75 nitrogen mass fraction (without carbon dioxide and water vapor) is 1630 K. The results show that increasing H2O percentage and decreasing CO2 percentage causes temperature uniformity and CO mass fraction decreasing at the chamber outlet.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

A. Cavaliere, M. de Joannon, Prog. Energy Combust. Sci. 30, 329–366 (2004). https://doi.org/10.1016/j.pecs.2004.02.003

J.A. Wünning, J.G. Wünning, Prog. Energy Combust. Sci. 23, 81–94 (1997). https://doi.org/10.1016/S0360-1285(97)00006-3

B. Ranjbar, M. Rahimi, F. Mohammadi, Int. J. Thermophys. 42, 99 (2021). https://doi.org/10.1007/s10765-021-02848-3

S. Jaikumar, V. Srinivas, R.S. Meher, Int. J. Thermophys. 42, 91 (2021). https://doi.org/10.1007/s10765-021-02842-9

Y. Cui, X. Lü, G. Xu, C. Nie, Sci. China Technol. Sci. 53, 2291–2298 (2010). https://doi.org/10.1007/s11431-010-4022-4

C. Galletti, A. Parente, M. Derudi, R. Rota, L. Tognotti, Int. J. Hydrogen Energy 34, 8339–8351 (2009). https://doi.org/10.1016/j.ijhydene.2009.07.095

S.R. Shabanian, P.R. Medwell, M. Rahimi, A. Frassoldati, A. Cuoci, Appl. Therm. Eng. 52, 538–554 (2013). https://doi.org/10.1016/j.applthermaleng.2012.12.024

J. Mi, P. Li, C. Zheng, Chin. J. Chem. Eng. 18, 10–17 (2010). https://doi.org/10.1016/S1004-9541(08)60316-X

Y. Tu, H. Liu, S. Chen, Z. Liu, H. Zhao, C. Zheng, Appl. Therm. Eng. 76, 64–75 (2015). https://doi.org/10.1016/j.applthermaleng.2014.11.007

A. Mardani, A.F. Ghomshi, Energy 99, 136–151 (2016). https://doi.org/10.1016/j.energy.2016.01.016

Y. Tu, M. Xu, D. Zhou, Q. Wang, W. Yang, H. Liu, Appl. Energy 240, 1003–1013 (2019). https://doi.org/10.1016/j.apenergy.2019.02.046

A. Khoshhal, M. Rahimi, A.A. Alsairafi, Heat Mass Transf. 38, 1421–1427 (2011)

M. Wang, J. Zhao, F. Guo, L. Zhu, D. Shen, X. Jiang, Therm. Sci. 26, 247–258 (2022). https://doi.org/10.2298/TSCI200916061W

S. Wang, Z. Yuan, A. Fan, Chem. Eng. Process. 139, 44–50 (2019). https://doi.org/10.1016/j.cep.2019.03.019

M. Mayrhofer, M. Koller, P. Seemann, R. Prieler, C. Hochenauer, Therm. Sci. Eng. Prog. 28, 101056 (2022). https://doi.org/10.1016/j.cep.2019.03.019

E. Salamon, I. Cornejo, J.P. Mmbaga, A. Kołodziej, J. Lojewska, R.E. Hayes, Chem. Eng. Process. 153, 107956 (2020). https://doi.org/10.1016/j.cep.2020.107956

M. Zhao, L. Liu, A. Fan, Chem. Eng. Process. 153, 108000 (2020). https://doi.org/10.1016/j.cep.2020.108000

A. Gholizadeh, S.R. Shabanian, M. Ghadirian, J. Ahmadpour. Int. J. Hydrogen Energy 47, 127–150 (2022). https://doi.org/10.1016/j.ijhydene.2021.10.005

Y. Tu, S. Xu, M. Xie, Z. Wang, H. Liu, Fuel 290, 119858 (2021). https://doi.org/10.1016/j.fuel.2020.119858

M. Huang, R. Li, J. Xu, S. Cheng, H. Deng, B. Zhang, Z. Rong, Y. Li, Fuel 302, 121179 (2021). https://doi.org/10.1016/j.fuel.2021.121179

Z. Zhang, X. Li, L. Zhang, C. Luo, Z. Mao, Y. Xu, J. Liu, G. Liu, C. Zheng, Fuel 237, 60–70 (2019). https://doi.org/10.1016/j.fuel.2018.09.133

X. Deng, Y. Xiong, H. Yin, Q. Gao, J. Energy Resour. Technol. 138, 042212 (2016). https://doi.org/10.1115/1.4033141

E.E. Fordoei, K. Mazaheri, A. Mohammadpour, Energy 218, 119524 (2021). https://doi.org/10.1016/j.energy.2020.119524

M. Mansourian, R. Kamali, Acta Astronaut. 162, 546–554 (2019). https://doi.org/10.1016/j.actaastro.2019.07.002

B. Razmjooei, A.R. Ravangard, L. Momayez, M. Ferchichi, J. Therm. Anal. Calorim. 147, 1901–1917 (2022). https://doi.org/10.1007/s10973-020-10263-3

M. Zharfa, N. Karimi, Acta Astronaut. 184, 259–268 (2021). https://doi.org/10.1016/j.actaastro.2021.04.023

S.H. Ajili, M. Haratian, A. Karimipour, Q.V. Bach, Int. J. Thermophys. 41, 128 (2020). https://doi.org/10.1007/s10765-020-02701-z

G. Wu, X. Wang, X. Xie, C. Ji, Z. Gao, C. Zhao, Int. J. Thermophys. 42, 114 (2021). https://doi.org/10.1007/s10765-021-02866-1

F. Wang, P. Li, J. Mi, Z. Shu, Fuel 292, 120315 (2021). https://doi.org/10.1016/j.fuel.2021.120315

A. Kazakov, M. Frenklach, Reduced reaction sets based on GRIMech 1.2 [Online]. Available: http://www.me.berkeley.edu/drm/

M. Frenklach, H. Wang, L. C-Yu, M. Goldenberg, C.T. Bowman, R.K. Hanson, et al. GRI-1.2. [Online]. Available: http://www.me.berkeley.edu/gri_mech/

Y. Afarin, S. Tabejamaat, Int. J. Hydrogen Energy 38, 3447–3458 (2013). https://doi.org/10.1016/j.ijhydene.2012.12.065

A. Mardani, S. Tabejamaat, Int. J. Hydrogen Energy 35, 11324–11331 (2010). https://doi.org/10.1016/j.ijhydene.2010.06.064

K. Cheong, G. Wang, J. Mi, B. Wang, R. Zhu, W. Ren, Energy Fuels 32, 8817–8829 (2018). https://doi.org/10.1021/acs.energyfuels.8b01587

P.R. Medwell, P.A. Kalt, B.B. Dally, Combust. Flame 52, 100–113 (2008). https://doi.org/10.1016/j.combustflame.2007.09.003

Y. Liu, S. Chen, S. Liu, Y. Feng, K. Xu, C. Zheng, Energy 115, 26–37 (2016). https://doi.org/10.1016/j.energy.2016.09.009

Funding

The authors acknowledge the funding support of Babol Noshirvani University of Technology through Grant Program No. BNUT/388003/97.

Author information

Authors and Affiliations

Contributions

SB: Conceptualization, Methodology, Software, Validation, Writing-original draft; SRS: Supervision, Methodology, Correspondence, Conceptualization, Software, Validation, Writing—review & editing; HB: Investigation, Validation, Data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Biabani, S., Shabanian, S.R. & Bakhshi, H. CFD Study on Influence of O2/CO2, O2/H2O Atmospheres and Shape of Furnace on Methane MILD Combustion. Int J Thermophys 44, 38 (2023). https://doi.org/10.1007/s10765-022-03151-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-022-03151-5