Abstract

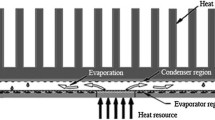

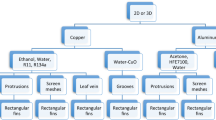

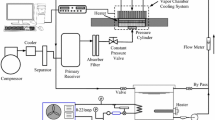

In this work, the temperature homogenization characteristics of a vapor chamber-type heat spreader were investigated. A copper vapor chamber with dimensions of 102 mm × 102 mm × 5 mm (width × length × thickness) was tested, and the distributions of the radial temperature and cumulative effective thermal conductivity across the heat spreading surface were measured at different working fluid charge ratios and heat fluxes. Water was employed as the working fluid at charge ratios of approximately 30%, 40%, and 60%. The vapor chamber was heated at the center within a heat flux range from 100 W·cm−2 to 200 W·cm−2 with a heat sink located at the peripheral edge to induce one-dimensional radial outward heat flow. Based on the obtained results, it was found that the temperature homogenization characteristics of the vapor chamber were significantly influenced by the working fluid charge ratio combined with the applied heat flux and heat sink temperature uniformity. Thus, to improve temperature homogeneity, the vapor chamber should be operated with a proper amount of the working fluid at a high heat flux (lower than the critical value causing drying) together with a heat sink of a high-temperature uniformity. Regarding the tested vapor chamber operated at a 30% working fluid charge ratio, which produced the lowest level of temperature asymmetry, the overall effective thermal conductivity ranged from 2460 W·m−1·K−1 ± 240 W·m−1·K−1 to 2910 W·m−1·K−1 ± 290 W·m−1·K−1 at 180 W·cm−2.

Similar content being viewed by others

Data Availability

All the raw data is available (if requested).

Abbreviations

- \({c}_{p}\) :

-

Isobaric-specific heat

- \(H\) :

-

Thickness of the vapor chamber-type heat spreader

- \({k}_{\mathrm{eff}}\) :

-

Effective thermal conductivity

- \({r}_{\mathrm{i}}\) :

-

Inner radial distance from the center

- \({r}_{\mathrm{o}}\) :

-

Outer radial distance from the center

- \(\rho\) :

-

Density

- \(\Delta {t}_{\mathrm{coolant}}\) :

-

Temperature change of the coolant

- \(\Delta {t}_{\mathrm{radial}}\) :

-

Radial temperature difference between \({r}_{\mathrm{i}}\) and \({r}_{\mathrm{o}}\)

- \({\dot{Q}}_{\mathrm{s}}\) :

-

Heat spread rate

- \({\dot{V}}_{\mathrm{coolant}}\) :

-

Flow rate of the coolant

- \(U\) :

-

Expanded uncertainty at approximately 95% level of confidence

References

D. Xie, Y. Sun, G. Wang, S. Chen, G. Ding, Int. J. Heat Mass Transf. 175, 121132 (2021). https://doi.org/10.1016/j.ijheatmasstransfer.2021.121132

H. Tang, Y. Tang, Z. Wan, J. Li, W. Yuan, L. Lu, Y. Li, K. Tang, Appl. Energy 223, 383 (2018). https://doi.org/10.1016/j.apenergy.2018.04.072

X. Chen, H. Ye, X. Fan, T. Ren, G. Zhang, Appl. Therm. Eng. 96, 1 (2016). https://doi.org/10.1016/j.applthermaleng.2015.11.048

A. Bar-Cohen, K. Martin, N. Jankowski, D. Sharar, J. Electron. Packag. 137, 010801 (2015). https://doi.org/10.1115/1.4028890

B. Blet, S. Lips, V. Sartre, Appl. Therm. Eng. 118, 490 (2017). https://doi.org/10.1016/j.applthermaleng.2017.03.009

L. Rosso, N. Koneva, V. Fernicola, Int. J. Thermophys. 30, 257 (2009). https://doi.org/10.1007/s10765-008-0495-9

F. Zhou, Y. Liu, E.M. Dede, J. Heat Transf. 141, 081802 (2019). https://doi.org/10.1115/1.4043797

J. Chen, J. Chou, Int. J. Heat Mass Transf. 77, 874 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2014.06.029

M.T. Ababneh, S. Chauhan, P. Chamarthy, F.M. Gerner, J. Heat Transf. 136, 112901 (2014). https://doi.org/10.1115/1.4028086

J. Chen, J. Chou, Int. J. Heat Mass Transf. 90, 848 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.06.032

J. Li, L. Lv, Appl. Therm. Eng. 93, 139 (2016). https://doi.org/10.1016/j.applthermaleng.2015.09.038

Z. Chen, Y. Li, W. Zhou, L. Deng, Y. Yan, Energy Conv. Manag. 187, 221 (2019). https://doi.org/10.1016/j.enconman.2019.03.038

G. Wang, Z. Quan, Y. Zhou, H. Wang, Appl. Therm. Eng. 146, 459 (2019). https://doi.org/10.1016/j.applthermaleng.2018.10.014

D. Lee, C. Byon, Int. J. Heat Mass Transf. 122, 306 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.01.135

S. Cho, Y. Joshi, J. Heat Transf. 141, 051401 (2019). https://doi.org/10.1115/1.4042328

D. Jafari, W.W. Wits, B.J. Geurts, Appl. Therm. Eng. 168, 114890 (2020). https://doi.org/10.1016/j.applthermaleng.2019.114890

J. Velardo et al., Int. J. Therm. Sci. 140, 28 (2019). https://doi.org/10.1016/j.ijthermalsci.2019.02.009

J. Velardo et al., Int. J. Heat Mass Transf. 145, 118797 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2019.118797

M. Wang, W. Cui, Y. Hou, Appl. Therm. Eng. 153, 361 (2019). https://doi.org/10.1016/j.applthermaleng.2019.03.025

C. Feng, M.J. Gibbons, M. Marengo, S. Chandra, Appl. Therm. Eng. 171, 115030 (2020). https://doi.org/10.1016/j.applthermaleng.2020.115030

Y.S. Ju et al., Int. J. Heat Mass Transf. 60, 163 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2012.12.058

H. P. J. de Bock et al, 2010 12th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (2010), p. 1. https://doi.org/10.1016/10.1109/ITHERM.2010.550132

Joint Committee for Guides in Metrology (JCGM), Evaluation of measurement data—Guide to the expression of uncertainty in measurement, JCGM 100:2008 (BIPM, Paris, 2008) pp. 18–23.

J. Carvill, Mechanical Engineer's Data Handbook, Butterworth-Heinemann (1993) pp. 102–145. https://doi.org/10.1016/B978-0-08-051135-1.50008-X

W. Joung, K.S. Gam, Y. Kim, I. Yang, Int. J. Heat Mass Transf. 65, 460 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2013.05.074

C. Park, W. Joung, Int. J. Heat Mass Transf. 186, 122 (2022). https://doi.org/10.1016/j.ijheatmasstransfer.2021.122472

S. Lips, F. Lefevre, J. Bonjour, Int. J. Heat Mass Transf. 53, 694 (2010). https://doi.org/10.1016/j.ijheatmasstransfer.2009.10.022

Acknowledgments

This work was supported by an Electronics and Telecommunications Research Institute (ETRI) grant provided by the ICT R&D program of MSIT/IITP (21IU1240; Development of a meso-scale high-speed heat spreader based on a super heat conducting technique).

Funding

This work was supported by an Electronics and Telecommunications Research Institute (ETRI) grant provided by the ICT R&D program of MSIT/IITP (21IU1240; Development of a meso-scale high-speed heat spreader based on a super heat conducting technique).

Author information

Authors and Affiliations

Contributions

Jonghak Han performed the experiment and wrote the main manuscript, Hyuncheol Bae specified the test conditions and prepared the test devices, and Wukchul Joung wrote the main manuscript and prepared figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, J., Bae, H. & Joung, W. Effect of the Working Fluid Charge Ratio and Heat Flux on the Temperature Homogenization Characteristics of a Vapor Chamber-Type Heat Spreader. Int J Thermophys 43, 168 (2022). https://doi.org/10.1007/s10765-022-03088-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-022-03088-9