Abstract

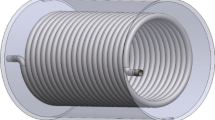

In this study, the effect of \({{Fe}}_{3}{{O}}_{4}\) magnetic nanoparticles on the efficiency of helically coiled tube heat exchanger (HCHE) has been investigated both numerically and experimentally. The solution of 20 % Ethylene glycol (EG) and distilled water is used as the base fluid. The effect of parameters including volume fraction of nanoparticles, coil inlet temperature, flow rate at the shell/coil side, and coil diameter on the heat transfer of the heat exchanger has been investigated. The results show that with increasing the flow rate on the coil side, the heat transfer coefficients and the Nusselt number are increased. It was observed that the heat transfer coefficient for the solution of distilled water-ethylene glycol increases by about 60 % with 0.1 volume fraction of \({{Fe}}_{3}{{O}}_{4}\) nanoparticles. As the coil inlet temperature increases from 40 \(^\circ{\rm C} \) to 60 \(^\circ{\rm C} \), the overall Nusselt number increases by 22 %. As expected, as the nanofluid flow rate increases, the heat transfer coefficient increases. For a wide range of flow rates, the internal and external heat transfer coefficients of the coil have been obtained.

Similar content being viewed by others

Abbreviations

- A:

-

Area, mm2

- \({C}_{1},{C}_{2},{C}_{1{\varepsilon }_{d}},{C}_{3{\varepsilon }_{d}}\) :

-

\(k-\varepsilon \) Turbulence model constants

- \({C}_{p}\) :

-

Specific heat, \( Jkg^{{ - 1}} \cdot K^{{ - 1}} \)

- D \((m)\) :

-

Tube diameter,\(m\)

- \({G}_{b}\) :

-

Generation of turbulent kinetic energy due to buoyancy

- \({G}_{k}\) :

-

Generation of turbulent kinetic energy due to the mean velocity gradients

- \(De\) :

-

Dean number

- \({d}_{np}(m)\) :

-

Diameter of nanoparticle, \(nm\)

- \({d}_{c}(m)\) :

-

Diameter of coil, \(mm\)

- EG :

-

Ethylene glycol

- \(\dot{m}\) :

-

Flow rate, \( kg \cdot s^{{ - 1}} \)

- \(h\) :

-

Heat transfer coefficient, \( W \cdot m^{{ - 2}} \cdot K^{{ - 1}} \)

- k :

-

Thermal conductivity, \( W \cdot m^{{ - 1}} \cdot K^{{ - 1}} \)

- \(Nu\) :

-

Nusselt number

- \(Pr\) :

-

Prandtl number

- \(Re\) :

-

Reynolds number

- \({S}_{ij}\) :

-

Deformation tensor

- \({S}_{k}\) :

-

Mean strain rate for \(k\)

- \(T (K)\) :

-

Temperature, \(K\)

- \(NTU\) :

-

Number of transfer units

- \(L\) :

-

Shell length, \(m\)

- \({P}_{outlet}\) :

-

Outlet pressure, \(Pa\)

- \(u\) :

-

Fluid velocity, \( m \cdot s^{{ - 1}} \)

- \(U\) :

-

Overall heat transfer coefficient, \( W \cdot m^{{ - 2}} .^{^\circ } {\text{C}} \)

- \({\Delta T}_{ln}\) :

-

Logarithmic mean temperature difference, \(K\)

- \( \rho (kg \cdot m^{{ - 3}} ) \) :

-

Density, \( kg \cdot m^{{ - 3}} \)

- \(\varphi \) :

-

Volume fraction of nanoparticles

- \(\mu \) :

-

Dynamic viscosity, \(Pa.s\)

- \({\sigma }_{k}\) :

-

Turbulence Prandtl number for \(k\)

- \(\varepsilon \) :

-

Heat exchanger efficiency

- \(c\) :

-

Coil

- \(sh\) :

-

Shell

- \(nf\) :

-

Nanofluid

- \(p\) :

-

Solid particle

- \(i\) :

-

Inlet

- \(o\) :

-

Outlet

- act:

-

Actual

- max:

-

Maximum

References

P.K. Sahoo, M.I.A. Ansari, A.K. Datta, A computer based iterative solution for accurate estimation of heat transfer coefficients in a helical tube heat exchanger. J. Food Eng. 58, 211–214 (2003). https://doi.org/10.1016/S0260-8774(02)00370-9

S. Chingulpitak, S. Wongwises, A comparison of flow characteristics of refrigerants flowing through adiabatic straight and helical capillary tubes. Int. Commun. Heat Mass Transf. (2011). https://doi.org/10.1016/j.icheatmasstransfer.2010.12.014

W.H. Park, C.K.K. Yang, Effects of using advanced cooling systems on the overall power consumption of processors, IEEE Trans. Very Large Scale Integr. Syst. (2013). https://doi.org/10.1109/TVLSI.2012.2217386

H. Ma, N. Du, Z. Zhang, F. Lyu, N. Deng, C. Li, S. Yu, Assessment of the optimum operation conditions on a heat pipe heat exchanger for waste heat recovery in steel industry. Renew. Sustain. Energy Rev. (2017). https://doi.org/10.1016/j.rser.2017.04.122

K. Chen, Y. Chen, Y. She, M. Song, S. Wang, L. Chen, Construction of effective symmetrical air-cooled system for battery thermal management. Appl. Therm. Eng. (2020). https://doi.org/10.1016/j.applthermaleng.2019.114679

B.A. Bhanvase, S.D. Sayankar, A. Kapre, P.J. Fule, S.H. Sonawane, Experimental investigation on intensified convective heat transfer coefficient of water based PANI nanofluid in vertical helical coiled heat exchanger. Appl. Therm. Eng. (2018). https://doi.org/10.1016/j.applthermaleng.2017.09.009

L.A.M. Janssen, C.J. Hoogendoorn, Laminar convective heat transfer in helical coiled tubes. Int. J. Heat Mass Transf. (1978). https://doi.org/10.1016/0017-9310(78)90138-2

P. Naphon, J. Suwagrai, Effect of curvature ratios on the heat transfer and flow developments in the horizontal spirally coiled tubes. Int. J. Heat Mass Transf. (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2006.08.002

J.S. Jayakumar, S.M. Mahajani, J.C. Mandal, K.N. Iyer, P.K. Vijayan, CFD analysis of single-phase flows inside helically coiled tubes. Comput. Chem. Eng. (2010). https://doi.org/10.1016/j.compchemeng.2009.11.008

R. Beigzadeh, M. Rahimi, Prediction of heat transfer and flow characteristics in helically coiled tubes using artificial neural networks. Int. Commun. Heat Mass Transf. (2012). https://doi.org/10.1016/j.icheatmasstransfer.2012.06.008

S.S. Pawar, V.K. Sunnapwar, Experimental and CFD investigation of convective heat transfer in helically coiled tube heat exchanger. Chem. Eng. Res. Des. (2014). https://doi.org/10.1016/j.cherd.2014.01.016

Y. Xuan, Q. Li, Investigation on convective heat transfer and flow features of nanofluids. J. Heat Transfer. (2003). https://doi.org/10.1115/1.1532008

G. Roy, C.T. Nguyen, P.R. Lajoie, Numerical investigation of laminar flow and heat transfer in a radial flow cooling system with the use of nanofluids. Superlattices Microstruct. (2004). https://doi.org/10.1016/j.spmi.2003.09.011

M. Shahul Hameed, S. Suresh, R.K. Singh, Comparative study of heat transfer and friction characteristics of water-based Alumina–copper and Alumina–CNT hybrid nanofluids in laminar flow through pipes, J (Anal. Calorim, Therm, 2019). https://doi.org/10.1007/s10973-018-7898-z

R. Essajai, I. Tabtab, A. Mzerd, O. Mounkachi, N. Hassanain, M. Qjani, Molecular dynamics study of thermal properties of nanofluids composed of one-dimensional (1-D) network of interconnected gold nanoparticles. Results Phys. (2019). https://doi.org/10.1016/j.rinp.2019.102576

M. Chandra Sekhara Reddy, V. Vasudeva Rao, Experimental investigation of heat transfer coefficient and friction factor of ethylene glycol water based TiO2 nanofluid in double pipe heat exchanger with and without helical coil inserts. Int. Commun. Heat Mass Transf. (2014). https://doi.org/10.1016/j.icheatmasstransfer.2013.11.002

N. Jamshidi, M. Farhadi, D.D. Ganji, K. Sedighi, Experimental analysis of heat transfer enhancement in shell and helical tube heat exchangers. Appl. Therm. Eng. (2013). https://doi.org/10.1016/j.applthermaleng.2012.10.008

K.Y. Leong, R. Saidur, S.N. Kazi, A.H. Mamun, Performance investigation of an automotive car radiator operated with nanofluid-based coolants (nanofluid as a coolant in a radiator). Appl. Therm. Eng. (2010). https://doi.org/10.1016/j.applthermaleng.2010.07.019

F. Akbaridoust, M. Rakhsha, A. Abbassi, M. Saffar-Avval, Experimental and numerical investigation of nanofluid heat transfer in helically coiled tubes at constant wall temperature using dispersion model. Int. J. Heat Mass Transf. (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2012.11.064

A. Alimoradi, F. Veysi, Prediction of heat transfer coefficients of shell and coiled tube heat exchangers using numerical method and experimental validation. Int. J. Therm. Sci. (2016). https://doi.org/10.1016/j.ijthermalsci.2016.04.010

A.S. Teja, P.Y. Koh, Synthesis, properties, and applications of magnetic iron oxide nanoparticles. Prog. Cryst. Growth Charact. Mater. (2009). https://doi.org/10.1016/j.pcrysgrow.2008.08.003

R.M. Cornell, U. Schwertmann (2003) The iron oxides: structure, properties, reactions, occurrences and uses: second ed.,

J. Ma, Y. Xu, W. Li, J. Zhao, S. Zhang, S. Basov, Experimental investigation into the forced convective heat transfer of aqueous Fe 3 O 4 nanofluids under transition region. J. Nanoparticles. (2013). https://doi.org/10.1155/2013/601363

L. Syam Sundar, M.K. Singh, A.C.M. Sousa, Investigation of thermal conductivity and viscosity of Fe3O4 nanofluid for heat transfer applications. Int. Commun. Heat Mass Transf. (2013). https://doi.org/10.1016/j.icheatmasstransfer.2013.02.014

S.V. Mousavi, M. Sheikholeslami, M. Gorji bandpy, M. Barzegar Gerdroodbary, The Influence of magnetic field on heat transfer of magnetic nanofluid in a sinusoidal double pipe heat exchanger. Chem. Eng. Res. Des. (2016). https://doi.org/10.1016/j.cherd.2016.07.009

N.T. Ravi Kumar, P. Bhramara, L.S. Sundar, M.K. Singh, A.C.M. Sousa, Heat transfer, friction factor and effectiveness of Fe3O4 nanofluid flow in an inner tube of double pipe U-bend heat exchanger with and without longitudinal strip inserts. Exp. Therm. Fluid Sci. (2017). https://doi.org/10.1016/j.expthermflusci.2017.03.019

L. Sha, Y. Ju, H. Zhang, J. Wang, Experimental investigation on the convective heat transfer of Fe3O4/water nanofluids under constant magnetic field. Appl. Therm. Eng. (2017). https://doi.org/10.1016/j.applthermaleng.2016.11.060

R.K. Ajeel, W.S.I.W. Salim, K. Hasnan, Experimental and numerical investigations of convection heat transfer in corrugated channels using alumina nanofluid under a turbulent flow regime. Chem. Eng. Res. Des. (2019). https://doi.org/10.1016/j.cherd.2019.06.003

M.R. Salem, K.M. Elshazly, R.Y. Sakr, R.K. Ali, Experimental investigation of coil curvature effect on heat transfer and pressure drop characteristics of shell and coil heat exchanger. J. Therm. Sci. Eng. Appl. (2015). https://doi.org/10.1115/1.4028612

A.D. Tuncer, A. Sözen, A. Khanlari, E.Y. Gürbüzb, H.İ Variyenli, Experimental and numerical analysis of a new modification for enhancing thermal performance of a shell and helically coiled heat exchanger. J. Applthermaleng (2020). https://doi.org/10.1016/.2020.116272

Y. Cengel, Heat Transfer: A Practical Approach, J. Chem. Inf. Model. (2013).

A.H. Rasheed, H.B. Alias, S.D. Salman, Experimental and numerical investigations of heat transfer enhancement in shell and helically microtube heat exchanger using nanofluids. Int. J. Therm. Sci. (2021). https://doi.org/10.1016/j.ijthermalsci.2020.106547

J. Koo, C. Kleinstreuer, Laminar nanofluid flow in microheat-sinks. Int. J. Heat Mass Transf. (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2005.01.029

K. Khanafer, K. Vafai, M. Lightstone, Buoyancy-driven heat transfer enhancement in a two-dimensional enclosure utilizing nanofluids. Int. J. Heat Mass Transf. (2003). https://doi.org/10.1016/S0017-9310(03)00156-X

N. Nithyadevi, P. Kandaswamy, J. Lee, Natural convection in a rectangular cavity with partially active side walls. Int. J. Heat Mass Transf. (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2007.03.050

I.H. Bell, J. Wronski, S. Quoilin, V. Lemort, Pure and pseudo-pure fluid thermophysical property evaluation and the open-source thermophysical property library coolprop. Ind. Eng. Chem. Res. (2014). https://doi.org/10.1021/ie4033999

J.I. Córcoles, J.D. Moya-Rico, A.E. Molina, J.A. Almendros-Ibáñez, Numerical and experimental study of the heat transfer process in a double pipe heat exchanger with inner corrugated tubes. Int. J. Therm. Sci. (2020). https://doi.org/10.1016/j.ijthermalsci.2020.106526

H.M. Maghrabie, M. Attalla, A.A.A. Mohsen, Performance assessment of a shell and helically coiled tube heat exchanger with variable orientations utilizing different nanofluids. J Applthermaleng (2020). https://doi.org/10.1016/j.applthermaleng.2020.116013

M. Attalla, H.M. Maghrabie, An experimental study on heat transfer and fluid flow of rough plate heat exchanger using Al2O3/water nanofluid. Exp. Heat Transf. 33, 261–281 (2020). https://doi.org/10.1080/08916152.2019.1625469

M. Attalla, Experimental investigation of heat transfer and pressure drop of SiO2/ water nanofluid through conduits with altered cross-sectional shapes. Heat Mass Transf. Und Stoffuebertragung. 55, 3427–3442 (2019). https://doi.org/10.1007/s00231-019-02668-0

O. Mahian, L. Kolsi, M. Amani, P. Estell´e, G. Ahmadi, C. Kleinstreuer, J.S. Marshall, M. Siavashi, R.A. Taylor, H. Niazmand, S. Wongwises, T. Hayat, A. Kolanjiyil, A. Kasaeian, I. Pop, Recent advances in modeling and simulation of nanofluid flows-Part I: fundamentals and theory. Phys. Rep. (2019). https://doi.org/10.1016/j.physrep.2018.11.004

Acknowledgements

The authors would also like to show their gratitude to the Razi University, Kermanshah, Iran, for providing the required location for performing the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghaderi, A., Veysi, F., Aminian, S. et al. Experimental and Numerical Study of Thermal Efficiency of Helically Coiled Tube Heat Exchanger Using Ethylene Glycol-Distilled Water Based Fe3O4 Nanofluid. Int J Thermophys 43, 118 (2022). https://doi.org/10.1007/s10765-022-03041-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-022-03041-w