Abstract

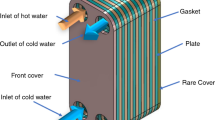

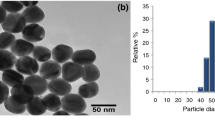

Heat exchanger plays a crucial role in the functioning of chemical industries, diary and food processing industries, and thermal plants. The enhancements in heat exchangers are mainly aimed at minimizing the energy consumption. An efficient heat exchanger is one that provides high heat transfer rate with minimum pumping power at low cost for energy saving. PHEs are used in various engineering fields due to their simplicity, flexibility, and maintainability related to others. In this paper, passive surface enhancement methods for single-phase and two-phase flow and application of nanofluids in different types of PHE are reviewed. The effect of geometrical parameters on hydraulic-thermal performance and occurrence of fouling deposits in PHE are also discussed. The chevron angle is found to be the most dominating geometrical parameter to change the flow properties. HTC, Nu, and ΔP increased with the increase in β, γ, and ϕ. For the two-phase flow, ΔP increased with the rise in vapor quality, mass flow rate and reduced with increase in saturation pressure. The optimum geometrical parameters for maximum heat transfer are β: 30°-60°, γ: 0.075–0.6, and φ: 1.18–1.3. The use of nanofluids in laminar flow condition is suggested by most of the literature.

Similar content being viewed by others

Abbreviations

- PHE:

-

Plate Heat Exchanger

- THE:

-

Tube Heat Exchanger

- HTC:

-

Heat transfer coefficient

- NTU:

-

Number of transfer unit

- CFD:

-

Computational fluid dynamics

- EG:

-

Ethylene glycol

- MWCNTs:

-

Multi-walled carbon nanotubes

- BHT:

-

Boiling heat transfer

- β :

-

Plate chevron angle (degree)

- λ :

-

Corrugation Pitch (mm)

- γ :

-

Channel profile aspect ratio

- φ :

-

Surface enlargement factor

- ϕ :

-

Nanoparticle concentration

- ε :

-

Heat exchanger effectiveness

- η :

-

Heat exchanger efficiency

- ρ :

-

Density (kg·m−3)

- μ :

-

Dynamic viscosity (Pa-s)

- eff :

-

Effective

- proj :

-

Projected

- h :

-

Hydraulic

- e :

-

Equivalent

- evap :

-

Evaporation

- cond :

-

Condensation

- w :

-

Water

- nf :

-

Nanofluid

- sat :

-

Saturation

- cfo :

-

Cold fluid at outlet

- cri :

-

Critical

- in :

-

Inlet

- L :

-

Plate length (mm)

- w :

-

Plate width (mm)

- t :

-

Plate thickness (mm)

- d :

-

Diameter (mm)

- r c :

-

Curvature radius

- b :

-

Corrugation depth (mm)

- H :

-

Height (mm)

- θ :

-

Intersection angle (degree)

- A :

-

Heat transfer area per plate (m2)

- S :

-

Channel spacing (mm)

- N :

-

Number of plates

- x :

-

Vapor quality

- T :

-

Temperature (°C)

- g :

-

Acceleration due to gravity (m·s−2)

- m :

-

Mass flow rate (kg·s−1)

- G :

-

Mass flux (kg·m−2·s−1)

- Q :

-

Heat transfer rate (watt)

- q ″ :

-

Heat flux (W·m−2)

- h :

-

Convective heat transfer coefficient (W·m−2·K−1)

- U m :

-

Overall heat transfer coefficient (W·m−2·K−1)

- u :

-

Fluid velocity (m·s−1)

- K :

-

Thermal conductivity (W·m−1·K−1)

- Δ P :

-

Frictional pressure drop (Pa)

- Nu :

-

Average Nusselt number

- Nu x :

-

Local Nusselt number

- Re :

-

Reynolds number

- Pr :

-

Prandtl number

- Pe :

-

Peclet number

- j :

-

Colburn factor

- f :

-

Friction factor

- R a :

-

Surface roughness

- Δ h :

-

Enthalpy change (kJ·kg−1)

References

W.M. Kays, A.L. London, E.R.G. Eckert, Compact heat exchangers. J. Appl. Mech. 27, 377 (1960). https://doi.org/10.1115/1.3644004

B. Sundén, R.M. Manglik, Plate heat exchangers: design, applications and performance, vol. 11 (Wit Press, New York, 2007)

W.M. Rohsenow, J.P. Hartnett, Y.I. Cho, Handbook of heat transfer, vol. 3 (McGraw-Hill, New York, 1998)

R.K. Shah, D.P. Sekulic, Fundamentals of heat exchanger design (Wiley, New York, 2003)

P. Stehlík, V.V. Wadekar, Different strategies to improve industrial heat exchange. Heat Transf. Eng. 23, 36–48 (2002)

M. Reppich, Use of high performance plate heat exchangers in chemical and process industries. Int. J. Therm. Sci. 38, 999–1008 (1999). https://doi.org/10.1016/S1290-0729(99)00109-X

M.M. Shah, Heat transfer during condensation in corrugated plate heat exchangers. Int. J. Refrig. 127, 180–193 (2021). https://doi.org/10.1016/j.ijrefrig.2021.02.011

K.M. Yashawantha, G. Gurjar, A.V. Vinod, Low temperature heat transfer in plate heat exchanger using ethylene glycol-water based Al2O3 nanofluid. Int. J. Thermophys. 42, 1–30 (2021). https://doi.org/10.1007/s10765-021-02843-8

K. Thulukkanam, Heat exchanger design handbook (CRC Press, New York, 2000)

R.K. Shah, Plate heat exchangers and their design theory. Heat Transf. Equip. Des. 227, 1 (1988)

A. Hajatzadeh Pordanjani, S. Aghakhani, M. Afrand, B. Mahmoudi, O. Mahian, S. Wongwises, An updated review on application of nanofluids in heat exchangers for saving energy. Energy Convers. Manag. 198, 111886 (2019). https://doi.org/10.1016/j.enconman.2019.111886

O.P. Arsenyeva, L.L. Tovazhnyanskyy, P.O. Kapustenko, G.L. Khavin, A.P. Yuzbashyan, P.Y. Arsenyev, Two types of welded plate heat exchangers for efficient heat recovery in industry. Appl. Therm. Eng. 105, 763–773 (2016). https://doi.org/10.1016/j.applthermaleng.2016.03.064

K. Sarraf, S. Launay, L. Tadrist, Complex 3D-flow analysis and corrugation angle effect in plate heat exchangers. Int. J. Therm. Sci. 94, 126–138 (2015). https://doi.org/10.1016/j.ijthermalsci.2015.03.002

G.F. Hewitt, J. Barbosa, Heat exchanger design handbook, vol. 98 (Begell House, New York, 2008)

H. Martin, A theoretical approach to predict the performance of chevron-type plate heat exchangers. Chem. Eng. Process. Process Intensif. 35, 301–310 (1996). https://doi.org/10.1016/0255-2701(95)04129-X

J. Zhang, X. Zhu, M.E. Mondejar, F. Haglind, A review of heat transfer enhancement techniques in plant heat exchanger. Renew. Sustain. Energy Rev. 101, 305–328 (2019). https://doi.org/10.1016/j.rser.2018.11.017

A.K. Tiwari, P. Ghosh, J. Sarkar, Performance comparison of the plate heat exchanger using different nanofluids. Exp. Therm. Fluid Sci. 49, 141–151 (2013). https://doi.org/10.1016/j.expthermflusci.2013.04.012

J.A.W. Gut, J.M. Pinto, Optimal configuration design for plate heat exchangers. Int. J. Heat Mass Transf. 47, 4833–4848 (2004). https://doi.org/10.1016/j.ijheatmasstransfer.2004.06.002

T.M. Abou Elmaaty, A.E. Kabeel, M. Mahgoub, Corrugated plate heat exchanger review. Renew. Sustain. Energy Rev. 70, 852–860 (2017). https://doi.org/10.1016/j.rser.2016.11.266

R.H.S. Winterton, Where did the Dittus and Boelter equation come from? Int. J. Heat Mass Transf. 41, 809–810 (1998)

H. Mori, S. Nakamura, F. Ono, K. Kariya, S. Umezawa, A study on characteristics of cooling heat transfer of supercritical pressure fluids in a plate heat exchanger. Heat Transf. Eng. 37, 659–667 (2016). https://doi.org/10.1080/01457632.2015.1067054

D.P. Soman, S. Karthika, P. Kalaichelvi, T.K. Radhakrishnan, Experimental study of turbulent forced convection heat transfer and friction factor in dimpled plate heat exchanger. Appl. Therm. Eng. 162, 114254 (2019). https://doi.org/10.1016/j.applthermaleng.2019.114254

R. Bogaert, A. Böles, Global performance of a prototype brazed plate heat exchanger in a large reynolds number range. Exp. Heat Transf. 8, 293–311 (1995). https://doi.org/10.1080/08916159508946508

A. Muley, Heat transfer and pressure drop in plate heat exchangers [Ph.D. thesis], Dept Mech. Ind. Nucl. Eng. Div Grad. Stud. Res. Univ. Cincinnati, 1997.

Y. Islamoglu, C. Parmaksizoglu, The effect of channel height on the enhanced heat transfer characteristics in a corrugated heat exchanger channel. Appl. Therm. Eng. 23, 979–987 (2003). https://doi.org/10.1016/S1359-4311(03)00029-2

J.A.W. Gut, R. Fernandes, J.M. Pinto, C.C. Tadini, Thermal model validation of plate heat exchangers with generalized configurations. Chem. Eng. Sci. 59, 4591–4600 (2004). https://doi.org/10.1016/j.ces.2004.07.025

T.S. Khan, M.S. Khan, M.C. Chyu, Z.H. Ayub, Experimental investigation of single phase convective heat transfer coefficient in a corrugated plate heat exchanger for multiple plate configurations. Appl. Therm. Eng. 30, 1058–1065 (2010). https://doi.org/10.1016/j.applthermaleng.2010.01.021

M. Faizal, M.R. Ahmed, Experimental studies on a corrugated plate heat exchanger for small temperature difference applications. Exp. Therm. Fluid Sci. 36, 242–248 (2012). https://doi.org/10.1016/j.expthermflusci.2011.09.019

O.P. Arsenyeva, L.L. Tovazhnyanskyy, P.O. Kapustenko, O.V. Demirskiy, Heat transfer and friction factor in criss-cross flow channels of plate-and-frame heat exchangers. Theor. Found. Chem. Eng. 46, 634–641 (2012). https://doi.org/10.1134/S0040579512060024

W.M. Abed, R.D. Whalley, D.J.C. Dennis, R.J. Poole, Numerical and experimental investigation of heat transfer and fluid flow characteristics in a micro-scale serpentine channel. Int. J. Heat Mass Transf. 88, 790–802 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.04.062

S. Hu, X. Ma, W. Zhou, Condensation heat transfer of ethanol-water vapor in a plate heat exchanger. Appl. Therm. Eng. 113, 1047–1055 (2017). https://doi.org/10.1016/j.applthermaleng.2016.11.013

S. Jin, P. Hrnjak, Effect of end plates on heat transfer of plate heat exchanger. Int. J. Heat Mass Transf. 108, 740–748 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.106

M.B. Kim, C.Y. Park, An experimental study on single phase convection heat transfer and pressure drop in two brazed plate heat exchangers with different chevron shapes and hydraulic diameters. J. Mech. Sci. Technol. 31, 2559–2571 (2017). https://doi.org/10.1007/s12206-017-0454-0

A. Sharif, B. Ameel, I. T’Jollyn, S. Lecompte, M. De Paepe, Comparative performance assessment of plate heat exchangers with triangular corrugation. Appl. Therm. Eng. 141, 186–199 (2018). https://doi.org/10.1016/j.applthermaleng.2018.05.111

D. Junqi, Z. Xianhui, W. Jianzhang, Experimental Study on Thermal Hydraulic Performance of Plate-Type Heat Exchanger Applied in Engine Waste Heat Recovery. Arab. J. Sci. Eng. 43, 1153–1163 (2018). https://doi.org/10.1007/s13369-017-2765-y

B. Kumar, A. Soni, S.N. Singh, Effect of geometrical parameters on the performance of chevron type plate heat exchanger. Exp. Therm. Fluid Sci. 91, 126–133 (2018). https://doi.org/10.1016/j.expthermflusci.2017.09.023

M.N. Khalaji, I. Kotcioglu, S. Caliskan, A. Cansiz, The second law analysis of thermodynamics for the plate-fin surface performance in a cross flow heat exchanger. J. Heat Transfer 141, 1 (2019). https://doi.org/10.1115/1.4041498

S. Mohebbi, F. Veysi, An experimental investigation on the heat transfer and friction coefficients of a small plate heat exchanger with chevron angle. Heat Mass Transf. Stoffuebertragung (2019). https://doi.org/10.1007/s00231-019-02749-0

M. Piper, A. Zibart, E. Djakow, R. Springer, W. Homberg, E.Y. Kenig, Heat transfer enhancement in pillow-plate heat exchangers with dimpled surfaces: a numerical study. Appl. Therm. Eng. 153, 142–146 (2019). https://doi.org/10.1016/j.applthermaleng.2019.02.082

J. Sodagar-Abardeh, A. Ebrahimi-Moghadam, M. Farzaneh-Gord, A. Norouzi, Optimizing chevron plate heat exchangers based on the second law of thermodynamics and genetic algorithm. J. Therm. Anal. Calorim. 139, 3563–3576 (2020). https://doi.org/10.1007/s10973-019-08742-3

O. Arsenyeva, J.J. Klemeš, P. Kapustenko, O. Fedorenko, S. Kusakov, D. Kobylnik, Plate heat exchanger design for the utilisation of waste heat from exhaust gases of drying process. Energy 233, 121186 (2021)

O. Arsenyeva, J. Jaromír Klemeš, S. Plankovskyy, P. Kapustenko, The influence of plate corrugation geometry on heat and mass transfer performance of plate heat exchangers for condensation of steam in the presence of air. Therm. Sci. Eng. Prog. 30, 101248 (2022). https://doi.org/10.1016/j.tsep.2022.101248

E.M.S. El-Said, S.M. Elshamy, A.A. Hegazi, Experimental investigation on thermo-hydraulic performance of a helical plate heat exchanger. Exp. Heat Transf. 1, 1–20 (2022)

A. Jafari, A. Sadeghianjahromi, C.-C. Wang, Experimental and numerical investigation of brazed plate heat exchangers – a new approach. Appl. Therm. Eng. 200, 117694 (2022). https://doi.org/10.1016/j.applthermaleng.2021.117694

N.K. Panday, S.N. Singh, Study of thermo-hydraulic performance of chevron type plate heat exchanger with wire inserts in the channel. Int. J. Therm. Sci. 173, 107360 (2022). https://doi.org/10.1016/j.ijthermalsci.2021.107360

Dovic and Svaic, Influence of chevron plates geometry on performances of plate heat exchangers. Teh. Vjesn. 14, 37–45 (2007)

J.H. Lin, C.Y. Huang, C.C. Su, Dimensional analysis for the heat transfer characteristics in the corrugated channels of plate heat exchangers. Int. Commun. Heat Mass Transf. 34, 304–312 (2007). https://doi.org/10.1016/j.icheatmasstransfer.2006.12.002

A.G. Kanaris, A.A. Mouza, S.V. Paras, Optimal design of a plate heat exchanger with undulated surfaces. Int. J. Therm. Sci. 48, 1184–1195 (2009). https://doi.org/10.1016/j.ijthermalsci.2008.11.001

Q.W. Wang, D.J. Zhang, G.N. Xie, Experimental study and genetic-algorithm-based correlation on pressure drop and heat transfer performances of a cross-corrugated primary surface heat exchanger. J. Heat Transfer 131, 1–8 (2009). https://doi.org/10.1115/1.3090716

W. Han, K. Saleh, V. Aute, G. Ding, Y. Hwang, R. Radermacher, Numerical simulation and optimization of single-phase turbulent flow in chevron-type plate heat exchanger with sinusoidal corrugations. HVAC R Res. 17, 186–197 (2011). https://doi.org/10.1080/10789669.2011.558167

D. Wang, Z. Liang, J. Zhou, H. Wang, The simulation research on the performance of chevron-type corrugated plate heat exchanger. Adv. Mater. Res. 383–390, 6502–6507 (2012). https://doi.org/10.4028/www.scientific.net/AMR.383-390.6502

L. Zhang, D. Che, Influence of corrugation profile on the thermalhydraulic performance of cross-corrugated plates. Numer. Heat Transf. Part A Appl. 59, 267–296 (2011). https://doi.org/10.1080/10407782.2011.540963

C.S. Guo, W.J. Du, L. Cheng, Characteristics of heat transfer and resistance of double chevron plate heat exchanges with different corrugation pitch. Adv. Intell. Soft Comput. 143, 169–174 (2012). https://doi.org/10.1007/978-3-642-27966-9_24

K. Shaji, S.K. Das, Effect of plate characteristics on axial dispersion and heat transfer in plate heat exchangers. J. Heat Transfer 135, 1–11 (2013). https://doi.org/10.1115/1.4022993

Y.H. Zhao, Y.F. Wu, H.J. Cheng, G.L. Zhu, Numerical simulation of corrugated depth on the performance of plate heat exchanger. Adv. Mater. Res. 860–863, 696–699 (2014). https://doi.org/10.4028/www.scientific.net/AMR.860-863.696

M. Kan, O. Ipek, B. Gurel, Plate heat exchangers as a compact design and optimization of different channel angles. Acta Phys. Pol. A 128, 49–52 (2015). https://doi.org/10.12693/APhysPolA.128.B-49

J. Lee, K.S. Lee, Friction and Colburn factor correlations and shape optimization of chevron-type plate heat exchangers. Appl. Therm. Eng. 89, 62–69 (2015). https://doi.org/10.1016/j.applthermaleng.2015.05.080

M. Krishna, M. Swamy, G. Manjunath, N. Rao, B. Rao, P. Murthy, Heat transfer enhancement in corrugated plate heat exchanger. Br. J. Appl. Sci. Technol. 18, 1–14 (2016). https://doi.org/10.9734/bjast/2016/28438

L. Vafajoo, K. Moradifar, S.M. Hosseini, B.H. Salman, Mathematical modelling of turbulent flow for flue gas-air Chevron type plate heat exchangers. Int. J. Heat Mass Transf. 97, 596–602 (2016). https://doi.org/10.1016/j.ijheatmasstransfer.2016.02.035

B. Kumar, S.N. Singh, Study of pressure drop in single pass U-type plate heat exchanger. Exp. Therm. Fluid Sci. 87, 40–49 (2017). https://doi.org/10.1016/j.expthermflusci.2017.04.028

B. Kılıç, O. İpek, Experimental investigation of heat transfer and effectiveness in corrugated plate heat exchangers having different chevron angles. Heat Mass Transf. Stoffuebertragung 53, 725–731 (2017). https://doi.org/10.1007/s00231-016-1817-2

J. Yang, A. Jacobi, W. Liu, Heat transfer correlations for single-phase flow in plate heat exchangers based on experimental data. Appl. Therm. Eng. 113, 1547–1557 (2017). https://doi.org/10.1016/j.applthermaleng.2016.10.147

Y. Zhicheng, W. Lijun, Y. Zhaokuo, L. Haowen, Shape optimization of welded plate heat exchangers based on grey correlation theory. Appl. Therm. Eng. 123, 761–769 (2017). https://doi.org/10.1016/j.applthermaleng.2017.05.005

O.Y. Dutta, B. Nageswara Rao, Investigations on the performance of chevron type plate heat exchangers. Heat Mass Transf. Stoffuebertragung 54, 227–239 (2018). https://doi.org/10.1007/s00231-017-2107-3

K. Nilpueng, T. Keawkamrop, H.S. Ahn, S. Wongwises, Effect of chevron angle and surface roughness on thermal performance of single-phase water flow inside a plate heat exchanger. Int. Commun. Heat Mass Transf. 91, 201–209 (2018). https://doi.org/10.1016/j.icheatmasstransfer.2017.12.009

J.A.W. Gut, J.M. Pinto, Modeling of plate heat exchangers with generalized configurations. Int. J. Heat Mass Transf. 46, 2571–2585 (2003). https://doi.org/10.1016/S0017-9310(03)00040-1

F.C.C. Galeazzo, R.Y. Miura, J.A.W. Gut, C.C. Tadini, Experimental and numerical heat transfer in a plate heat exchanger. Chem. Eng. Sci. 61, 7133–7138 (2006). https://doi.org/10.1016/j.ces.2006.07.029

G.M. Zhang, M.C. Tian, S.J. Zhou, Simulation and analysis of flow pattern in cross-corrugated plate heat exchangers. J. Hydrodyn. 18, 547–551 (2006). https://doi.org/10.1016/S1001-6058(06)60133-9

C.S. Fernandes, R.P. Dias, J.M. Nóbrega, J.M. Maia, Laminar flow in chevron-type plate heat exchangers: CFD analysis of tortuosity, shape factor and friction factor. Chem. Eng. Process. Process Intensif. 46, 825–833 (2007). https://doi.org/10.1016/j.cep.2007.05.011

M. El Haj Assad, V.W. Kotiaho, Analysis of a parallel-flow heat exchanger with a heat source. Heat Transf. Eng. 32, 384–389 (2011). https://doi.org/10.1080/01457632.2010.483863

I. Gherasim, N. Galanis, C.T. Nguyen, Heat transfer and fluid flow in a plate heat exchanger. Part II: Assessment of laminar and two-equation turbulent models. Int. J. Therm. Sci. 50, 1499–1511 (2011). https://doi.org/10.1016/j.ijthermalsci.2011.03.017

V. Patil, H. Manjunath, B. Kusammanavar, Validation of plate heat exchanger design using CFD. Int. J. Mech. Eng. Robot. Res. 2, 222–230 (2013)

O. Giurgiu, A. Pleşa, L. Socaciu, Plate Heat Exchangers - Flow Analysis through Mini Channels. Energy Proc. 85, 244–251 (2016). https://doi.org/10.1016/j.egypro.2015.12.236

A. Bejan, M. Alalaimi, S. Lorente, A.S. Sabau, J.W. Klett, Counterflow heat exchanger with core and plenums at both ends. Int. J. Heat Mass Transf. 99, 622–629 (2016). https://doi.org/10.1016/j.ijheatmasstransfer.2016.03.117

M. Asif, H. Aftab, H.A. Syed, M.A. Ali, P.M. Muizz, Simulation of corrugated plate heat exchanger for heat and flow analysis. Int. J. Heat Technol. 35, 205–210 (2017). https://doi.org/10.18280/ijht.350127

Y. Wang, S. You, W. Zheng, H. Zhang, X. Zheng, Q. Miao, State space model and robust control of plate heat exchanger for dynamic performance improvement. Appl. Therm. Eng. 128, 1588–1604 (2018). https://doi.org/10.1016/j.applthermaleng.2017.09.120

T.W. Lim, Y.S. Choi, C.K. Lee, Design of plate heat exchangers for use in medium temperature organic Rankine cycles. Heat Mass Transf. Stoffuebertragung 55, 165–174 (2019). https://doi.org/10.1007/s00231-018-2446-8

A.M. González, M. Vaz, P.S.B. Zdanski, A hybrid numerical-experimental analysis of heat transfer by forced convection in plate-finned heat exchangers. Appl. Therm. Eng. 148, 363–370 (2019). https://doi.org/10.1016/j.applthermaleng.2018.11.068

J.S. Rincón Tabares, L. Perdomo-Hurtado, J.L. Aragón, Study of Gasketed-Plate Heat Exchanger performance based on energy efficiency indexes. Appl. Therm. Eng. 159, 113902 (2019). https://doi.org/10.1016/j.applthermaleng.2019.113902

M.S. Islam, S.C. Saha, Heat transfer enhancement investigation in a novel flat plate heat exchanger. Int. J. Therm. Sci. 161, 106763 (2021)

A. Norouzi, J. Sodagar-Abardeh, A. Arabkoohsar, K.A.R. Ismail, Investigating thermo-hydraulic behavior of pillow plate heat exchangers using entropy generation approach. Chem. Eng. Process. - Process Intensif. 174, 108887 (2022). https://doi.org/10.1016/j.cep.2022.108887

A. Sadeghianjahromi, A. Jafari, C.-C. Wang, Numerical investigation of the effect of chevron angle on thermofluids characteristics of non-mixed and mixed brazed plate heat exchangers with experimental validation. Int. J. Heat Mass Transf. 184, 122278 (2022). https://doi.org/10.1016/j.ijheatmasstransfer.2021.122278

M. Shirzad, S.S.M. Ajarostaghi, M.A. Delavar, K. Sedighi, Improve the thermal performance of the pillow plate heat exchanger by using nanofluid: Numerical simulation. Adv. Powder Technol. 30, 1356–1365 (2019). https://doi.org/10.1016/j.apt.2019.04.011

A. Bhattad, J. Sarkar, P. Ghosh, Discrete phase numerical model and experimental study of hybrid nanofluid heat transfer and pressure drop in plate heat exchanger. Int. Commun. Heat Mass Transf. 91, 262–273 (2018). https://doi.org/10.1016/j.icheatmasstransfer.2017.12.020

D. Zheng, J. Wang, Z. Chen, J. Baleta, B. Sundén, Performance analysis of a plate heat exchanger using various nanofluids. Int. J. Heat Mass Transf. (2020). https://doi.org/10.1016/j.ijheatmasstransfer.2020.119993

C.A.R. do Nascimento, V.C. Mariani, L. Dos. S. Coelho, Integrative numerical modeling and thermodynamic optimal design of counter-flow plate-fin heat exchanger applying neural networks. Int. J. Heat Mass Transf. 159, 120097 (2020). https://doi.org/10.1016/j.ijheatmasstransfer.2020.120097

K. Li, J. Wen, S. Wang, Y. Li, Multi-parameter optimization of serrated fins in plate-fin heat exchanger based on fluid-structure interaction. Appl. Therm. Eng. (2020). https://doi.org/10.1016/j.applthermaleng.2020.115357

A. Desideri et al., An experimental analysis of flow boiling and pressure drop in a brazed plate heat exchanger for organic Rankine cycle power systems. Int. J. Heat Mass Transf. 113, 6–21 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.063

M. Imran, M. Usman, Y. Yang, B.S. Park, Flow boiling of R245fa in the brazed plate heat exchanger: Thermal and hydraulic performance assessment. Int. J. Heat Mass Transf. 110, 657–670 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.03.070

W.Y. Saman, S. Alizadeh, An experimental study of a cross-flow type plate heat exchanger for dehumidification/cooling. Sol. Energy 73, 59–71 (2002). https://doi.org/10.1016/S0038-092X(01)00078-0

J. Zhang, A. Desideri, M.R. Kærn, T.S. Ommen, J. Wronski, F. Haglind, Flow boiling heat transfer and pressure drop characteristics of R134a, R1234yf and R1234ze in a plate heat exchanger for organic Rankine cycle units. Int. J. Heat Mass Transf. 108, 1787–1801 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.01.026

D. Kim, D.C. Lee, D.S. Jang, Y. Jeon, Y. Kim, Comparative evaluation of flow boiling heat transfer characteristics of R-1234ze(E) and R-134a in plate heat exchangers with different Chevron angles. Appl. Therm. Eng. 132, 719–729 (2018). https://doi.org/10.1016/j.applthermaleng.2018.01.019

D.H. Han, K.J. Lee, Y.H. Kim, Experiments on the characteristics of evaporation of R410A in brazed plate heat exchangers with different geometric configurations. Appl. Therm. Eng. 23, 1209–1225 (2003). https://doi.org/10.1016/S1359-4311(03)00061-9

D.H. Han, K.J. Lee, Y.H. Kim, The characteristics of condensation in brazed plate heat exchangers with different chevron angles. J. Korean Phys. Soc. 43, 66–73 (2003)

R. Würfel, N. Ostrowski, Experimental investigations of heat transfer and pressure drop during the condensation process within plate heat exchangers of the herringbone-type. Int. J. Therm. Sci. 43, 59–68 (2004). https://doi.org/10.1016/S1290-0729(03)00099-1

E. Djordjevic, S. Kabelac, Flow boiling of R134a and ammonia in a plate heat exchanger. Int. J. Heat Mass Transf. 51, 6235–6242 (2008). https://doi.org/10.1016/j.ijheatmasstransfer.2008.01.042

N. Hayes, A. Jokar, Z.H. Ayub, Study of carbon dioxide condensation in chevron plate exchangers; Heat transfer analysis. Int. J. Heat Mass Transf. 54, 1121–1131 (2011). https://doi.org/10.1016/j.ijheatmasstransfer.2010.11.010

N. Hayes, A. Jokar, Z.H. Ayub, Study of carbon dioxide condensation in chevron plate exchangers; Pressure drop analysis. Int. J. Heat Mass Transf. 55, 2916–2925 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2012.02.013

J. Huang, T.J. Sheer, M. Bailey-Mcewan, Heat transfer and pressure drop in plate heat exchanger refrigerant evaporators. Int. J. Refrig. 35, 325–335 (2012). https://doi.org/10.1016/j.ijrefrig.2011.11.002

M.S. Khan, T.S. Khan, M.-C. Chyu, Z.H. Ayub, Experimental investigation of evaporation heat transfer and pressure drop of ammonia in a 30 chevron plate heat exchanger. Int. J. Refrig. 35, 1757–1765 (2012)

T.S. Khan, M.S. Khan, M.C. Chyu, Z.H. Ayub, Experimental investigation of evaporation heat transfer and pressure drop of ammonia in a 60° chevron plate heat exchanger. Int. J. Refrig. 35, 336–348 (2012). https://doi.org/10.1016/j.ijrefrig.2011.10.018

A. Müller, S. Kabelac, The experimental determination of heat transfer and pressure drop during condensation in a plate heat exchanger with corrugated plates. WIT Trans. Eng. Sci. 83, 337–349 (2014). https://doi.org/10.2495/HT140301

M.S. Khan, T.S. Khan, M.C. Chyu, Z.H. Ayub, Evaporation heat transfer and pressure drop of ammonia in a mixed configuration chevron plate heat exchanger. Int. J. Refrig. 41, 92–102 (2014). https://doi.org/10.1016/j.ijrefrig.2013.12.015

G. Bamorovat Abadi, D.Y. Kim, S.Y. Yoon, K.C. Kim, Thermal performance of a 10-kW phase-change plate heat exchanger with metal foam filled channels. Appl. Therm. Eng. 99, 790–801 (2016). https://doi.org/10.1016/j.applthermaleng.2016.01.156

R. Eldeeb, V. Aute, R. Radermacher, A survey of correlations for heat transfer and pressure drop for evaporation and condensation in plate heat exchangers. Int. J. Refrig. 65, 12–26 (2016). https://doi.org/10.1016/j.ijrefrig.2015.11.013

K. Miyata, H. Mori, T. Taniguchi, S. Umezawa, K. Sugita, Effect of the Chevron angle on cooling heat transfer characteristics of supercritical pressure fluids in plate heat exchangers. Heat Transf. Eng. 40, 1007–1022 (2019). https://doi.org/10.1080/01457632.2018.1450334

A. Durmuş, H. Benli, I. Kurtbaş, H. Gül, Investigation of heat transfer and pressure drop in plate heat exchangers having different surface profiles. Int. J. Heat Mass Transf. 52, 1451–1457 (2009). https://doi.org/10.1016/j.ijheatmasstransfer.2008.07.052

K. Nilpueng, S. Wongwises, Experimental study of single-phase heat transfer and pressure drop inside a plate heat exchanger with a rough surface. Exp. Therm. Fluid Sci. 68, 268–275 (2015). https://doi.org/10.1016/j.expthermflusci.2015.04.009

K. Subramani, K. Logesh, S. Kolappan, S. Karthik, Experimental investigation on heat transfer characteristics of heat exchanger with bubble fin assistance. Int. J. Ambient Energy 41, 617–620 (2020). https://doi.org/10.1080/01430750.2018.1472654

S. Al, M.S. Islam, S.C. Saha, Heat transfer enhancement of modified flat plate heat exchanger. Appl. Therm. Eng. 186, 116533 (2021). https://doi.org/10.1016/j.applthermaleng.2020.116533

Y. Zhang, C. Jiang, Z. Yang, Y. Zhang, B. Bai, Numerical study on heat transfer enhancement in capsule-type plate heat exchangers. Appl. Therm. Eng. 108, 1237–1242 (2016). https://doi.org/10.1016/j.applthermaleng.2016.08.033

Z. jian LUAN, G. min ZHANG, M. cheng TIAN, and M. xiu FAN, “Flow resistance and heat transfer characteristics of a new-type plate heat exchanger,” J. Hydrodyn., vol. 20, no. 4, pp. 524–529, 2008, doi: https://doi.org/10.1016/S1001-6058(08)60089-X.

J.Y. Jeong, H. Hong, S.K. Kim, Y.T. Kang, Impact of plate design on the performance of welded type plate heat exchangers for sorption cycles. Int. J. Refrig. 32, 705–711 (2009). https://doi.org/10.1016/j.ijrefrig.2009.01.028

M. Kim, Y.J. Baik, S.R. Park, H.S. Ra, H. Lim, Experimental study on corrugated cross-flow air-cooled plate heat exchangers. Exp. Therm. Fluid Sci. 34, 1265–1272 (2010). https://doi.org/10.1016/j.expthermflusci.2010.05.007

D.B. Monteiro, P.E.B. de Mello, Thermal performance and pressure drop in a ceramic heat exchanger evaluated using CFD simulations. Energy 45, 489–496 (2012). https://doi.org/10.1016/j.energy.2012.02.012

J.H. Doo, M.Y. Ha, J.K. Min, R. Stieger, A. Rolt, C. Son, An investigation of cross-corrugated heat exchanger primary surfaces for advanced intercooled-cycle aero engines (Part-I: Novel geometry of primary surface). Int. J. Heat Mass Transf. 55, 5256–5267 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2012.05.034

J.H. Doo, M.Y. Ha, J.K. Min, R. Stieger, A. Rolt, C. Son, An investigation of cross-corrugated heat exchanger primary surfaces for advanced intercooled-cycle aero engines (Part-II: Design optimization of primary surface). Int. J. Heat Mass Transf. 61, 138–148 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2013.01.084

H.H.S. Villanueva, P.E.B. de Mello, Heat transfer and pressure drop correlations for finned plate ceramic heat exchangers. Energy 88, 118–125 (2015). https://doi.org/10.1016/j.energy.2015.04.017

J.M. Lee, P.W. Kwan, C.M. Son, M.Y. Ha, Characterizations of aerothermal performance of novel cross-corrugated plate heat exchangers for advanced cycle aero-engines. Int. J. Heat Mass Transf. 85, 166–180 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.127

J. Wajs, D. Mikielewicz, Influence of metallic porous microlayer on pressure drop and heat transfer of stainless steel plate heat exchanger. Appl. Therm. Eng. 93, 1337–1346 (2016). https://doi.org/10.1016/j.applthermaleng.2015.08.101

C. Zhang, D. Wang, Y. Han, Y. Zhu, X. Peng, Experimental and numerical investigation on the exergy and entransy performance of a novel plate heat exchanger. Exp. Heat Transf. 30, 162–177 (2017). https://doi.org/10.1080/08916152.2016.1179358

G. Bamorovat Abadi, C. Moon, K.C. Kim, Experimental study on single-phase heat transfer and pressure drop of refrigerants in a plate heat exchanger with metal-foam-filled channels. Appl. Therm. Eng. 102, 423–431 (2016). https://doi.org/10.1016/j.applthermaleng.2016.03.099

R.L. Amalfi, F. Vakili-Farahani, J.R. Thome, Flow boiling and frictional pressure gradients in plate heat exchangers. Part 1: Review and experimental database. Int. J. Refrig. 61, 166–184 (2016). https://doi.org/10.1016/j.ijrefrig.2015.07.010

J. Soontarapiromsook, O. Mahian, A.S. Dalkilic, S. Wongwises, Effect of surface roughness on the condensation of R-134a in vertical chevron gasketed plate heat exchangers. Exp. Therm. Fluid Sci. 91, 54–63 (2018). https://doi.org/10.1016/j.expthermflusci.2017.09.015

S.K. Das, N. Putra, P. Thiesen, W. Roetzel, Temperature dependence of thermal conductivity enhancement for nanofluids. J. Heat Transfer 125, 567–574 (2003). https://doi.org/10.1115/1.1571080

Y. Xuan, Q. Li, Heat transfer enhancement of nanofluids. Int. J. Heat Fluid Flow 21, 58–64 (2000). https://doi.org/10.1016/S0142-727X(99)00067-3

M. Attalla, H.M. Maghrabie, Investigation of effectiveness and pumping power of plate heat exchanger with rough surface. Chem. Eng. Sci. 211, 115277 (2020). https://doi.org/10.1016/j.ces.2019.115277

S.K. Das, S.U.S. Choi, H.E. Patel, Heat transfer in nanofluids - A review. Heat Transf. Eng. 27, 3–19 (2006). https://doi.org/10.1080/01457630600904593

T. Maré, S. Halelfadl, O. Sow, P. Estellé, S. Duret, F. Bazantay, Comparison of the thermal performances of two nanofluids at low temperature in a plate heat exchanger. Exp. Therm. Fluid Sci. 35, 1535–1543 (2011). https://doi.org/10.1016/j.expthermflusci.2011.07.004

S.D. Pandey, V.K. Nema, Experimental analysis of heat transfer and friction factor of nanofluid as a coolant in a corrugated plate heat exchanger. Exp. Therm. Fluid Sci. 38, 248–256 (2012). https://doi.org/10.1016/j.expthermflusci.2011.12.013

A.E. Kabeel, T. Abou El Maaty, Y. El Samadony, The effect of using nano-particles on corrugated plate heat exchanger performance. Appl. Therm. Eng. 52, 221–229 (2013). https://doi.org/10.1016/j.applthermaleng.2012.11.027

A.K. Tiwari, P. Ghosh, J. Sarkar, Heat transfer and pressure drop characteristics of CeO2/water nanofluid in plate heat exchanger. Appl. Therm. Eng. 57, 24–32 (2013). https://doi.org/10.1016/j.applthermaleng.2013.03.047

A. Jokar, S.P. O’Halloran, Heat transfer and fluid flow analysis of nanofluids in corrugated plate heat exchangers using computational fluid dynamics simulation. J. Therm. Sci. Eng. Appl. 5, 1–10 (2013). https://doi.org/10.1115/1.4007777

A. Tohidi, S.M. Hosseinalipour, P. Taheri, N.M. Nouri, A.S. Mujumdar, Chaotic advection induced heat transfer enhancement in a chevron-type plate heat exchanger. Heat Mass Transf. Stoffuebertragung 49, 1535–1548 (2013). https://doi.org/10.1007/s00231-013-1180-5

C. Gulenoglu, F. Akturk, S. Aradag, N. Sezer Uzol, S. Kakac, Experimental comparison of performances of three different plates for gasketed plate heat exchangers. Int. J. Therm. Sci. 75, 249–256 (2014). https://doi.org/10.1016/j.ijthermalsci.2013.06.012

J. Lee, K.S. Lee, Flow characteristics and thermal performance in chevron type plate heat exchangers. Int. J. Heat Mass Transf. 78, 699–706 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2014.07.033

M.A. Khairul, M.A. Alim, I.M. Mahbubul, R. Saidur, A. Hepbasli, A. Hossain, Heat transfer performance and exergy analyses of a corrugated plate heat exchanger using metal oxide nanofluids. Int. Commun. Heat Mass Transf. 50, 8–14 (2014). https://doi.org/10.1016/j.icheatmasstransfer.2013.11.006

J. Ham, J. Kim, H. Cho, Theoretical analysis of thermal performance in a plate type liquid heat exchanger using various nanofluids based on LiBr solution. Appl. Therm. Eng. 108, 1020–1032 (2016). https://doi.org/10.1016/j.applthermaleng.2016.07.196

A.M. Abed, M.A. Alghoul, K. Sopian, H.A. Mohammed, H. Majdi, A.N. Al-Shamani, Design characteristics of corrugated trapezoidal plate heat exchangers using nanofluids. Chem. Eng. Process. Process Intensif. 87, 88–103 (2015). https://doi.org/10.1016/j.cep.2014.11.005

D. Huang, Z. Wu, B. Sunden, Pressure drop and convective heat transfer of Al2O3/water and MWCNT/water nanofluids in a chevron plate heat exchanger. Int. J. Heat Mass Transf. 89, 620–626 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.082

M. Goodarzi et al., Investigation of heat transfer and pressure drop of a counter flow corrugated plate heat exchanger using MWCNT based nanofluids. Int. Commun. Heat Mass Transf. 66, 172–179 (2015). https://doi.org/10.1016/j.icheatmasstransfer.2015.05.002

V. Kumar, A.K. Tiwari, S.K. Ghosh, Application of nanofluids in plate heat exchanger: A review. Energy Convers. Manag. 105, 1017–1036 (2015). https://doi.org/10.1016/j.enconman.2015.08.053

A. Behrangzade, M.M. Heyhat, The effect of using nano-silver dispersed water based nanofluid as a passive method for energy efficiency enhancement in a plate heat exchanger. Appl. Therm. Eng. 102, 311–317 (2016). https://doi.org/10.1016/j.applthermaleng.2016.03.051

B. Sun, C. Peng, R. Zuo, D. Yang, H. Li, Investigation on the flow and convective heat transfer characteristics of nanofluids in the plate heat exchanger, vol. 76 (Elsevier, Amsterdam, 2016)

S.H. Pourhoseini, N. Naghizadeh, H. Hoseinzadeh, Effect of silver-water nanofluid on heat transfer performance of a plate heat exchanger: An experimental and theoretical study. Powder Technol. 332, 279–286 (2018). https://doi.org/10.1016/j.powtec.2018.03.058

A. Khanlari, A. Sözen, H.İ Variyenli, Simulation and experimental analysis of heat transfer characteristics in the plate type heat exchangers using TiO2/water nanofluid. Int. J. Numer. Methods Heat Fluid Flow 29, 1343–1362 (2019). https://doi.org/10.1108/HFF-05-2018-0191

N.S. Pandya, H. Shah, M. Molana, A.K. Tiwari, Heat transfer enhancement with nanofluids in plate heat exchangers: A comprehensive review. Eur. J. Mech. B/Fluids 81, 173–190 (2020). https://doi.org/10.1016/j.euromechflu.2020.02.004

B. Saleh, L.S. Sundar, Experimental study on heat transfer, friction factor, entropy and exergy efficiency analyses of a corrugated plate heat exchanger using Ni/water nanofluids. Int. J. Therm. Sci. 165, 106935 (2021). https://doi.org/10.1016/j.ijthermalsci.2021.106935

I.A. Stogiannis, A.A. Mouza, S.V. Paras, Efficacy of SiO2 nanofluids in a miniature plate heat exchanger with undulated surface. Int. J. Therm. Sci. 92, 230–238 (2015). https://doi.org/10.1016/j.ijthermalsci.2015.01.035

Z. Wang, Z. Wu, F. Han, L. Wadsö, B. Sundén, Experimental comparative evaluation of a graphene nanofluid coolant in miniature plate heat exchanger. Int. J. Therm. Sci. 130, 148–156 (2018). https://doi.org/10.1016/j.ijthermalsci.2018.04.021

M.N. Pantzali, A.A. Mouza, S.V. Paras, Investigating the efficacy of nanofluids as coolants in plate heat exchangers (PHE). Chem. Eng. Sci. 64, 3290–3300 (2009). https://doi.org/10.1016/j.ces.2009.04.004

R. Barzegarian, M.K. Moraveji, A. Aloueyan, Experimental investigation on heat transfer characteristics and pressure drop of BPHE (brazed plate heat exchanger) using TiO2-water nanofluid. Exp. Therm. Fluid Sci. 74, 11–18 (2016). https://doi.org/10.1016/j.expthermflusci.2015.11.018

D.R. Ray, D.K. Das, R.S. Vajjha, Experimental and numerical investigations of nanofluids performance in a compact minichannel plate heat exchanger. Int. J. Heat Mass Transf. 71, 732–746 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2013.12.072

Z.X. Li, U. Khaled, A.A.A.A. Al-Rashed, M. Goodarzi, M.M. Sarafraz, R. Meer, Heat transfer evaluation of a micro heat exchanger cooling with spherical carbon-acetone nanofluid. Int. J. Heat Mass Transf. (2020). https://doi.org/10.1016/j.ijheatmasstransfer.2019.119124

A.A. Abbasian Arani, J. Amani, Experimental investigation of diameter effect on heat transfer performance and pressure drop of TiO2-water nanofluid. Exp. Therm. Fluid Sci. 44, 520–533 (2013). https://doi.org/10.1016/j.expthermflusci.2012.08.014

C. Qi, T. Luo, M. Liu, F. Fan, Y. Yan, Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers. Manag. 197, 111877 (2019). https://doi.org/10.1016/j.enconman.2019.111877

M.H. Fard, M.R. Talaie, S. Nasr, Numerical and experimental investigation of heat transfer of zno/water nanofluid in the concentric tube and plate heat exchangers. Therm. Sci. 15, 183–194 (2011). https://doi.org/10.2298/TSCI091103048H

M. Hojjat, S.G. Etemad, R. Bagheri, J. Thibault, Convective heat transfer of non-Newtonian nanofluids through a uniformly heated circular tube. Int. J. Therm. Sci. 50, 525–531 (2011). https://doi.org/10.1016/j.ijthermalsci.2010.11.006

M.H. Kayhani, H. Soltanzadeh, M.M. Heyhat, M. Nazari, F. Kowsary, Experimental study of convective heat transfer and pressure drop of TiO 2/water nanofluid. Int. Commun. Heat Mass Transf. 39, 456–462 (2012). https://doi.org/10.1016/j.icheatmasstransfer.2012.01.004

R.N. Radkar, B.A. Bhanvase, D.P. Barai, S.H. Sonawane, Intensified convective heat transfer using ZnO nanofluids in heat exchanger with helical coiled geometry at constant wall temperature. Mater. Sci. Energy Technol. 2, 161–170 (2019). https://doi.org/10.1016/j.mset.2019.01.007

P. C. Mukesh Kumar and M. Chandrasekar, “CFD analysis on heat and flow characteristics of double helically coiled tube heat exchanger handling MWCNT/water nanofluids,” Heliyon, vol. 5, no. 7, p. e02030, 2019, doi: https://doi.org/10.1016/j.heliyon.2019.e02030.

A. Bhattad, J. Sarkar, P. Ghosh, Experimentation on effect of particle ratio on hydrothermal performance of plate heat exchanger using hybrid nanofluid. Appl. Therm. Eng. 162, 114309–114319 (2019). https://doi.org/10.1016/j.applthermaleng.2019.114309

S. Rostami, A. Aghaei, A. Hassani, J. Hossein, M. Hezaveh, and M. Sharifpur, “Thermal – hydraulic efficiency management of spiral heat exchanger filled with Cu – ZnO / water hybrid nanofluid,” no. mm, 2020.

F. Afshari, A comprehensive survey on utilization of hybrid nanofluid in plate heat exchanger with various number of plates. Int. J. Numer. Methods Heat Fluid Flow 32, 241–264 (2022). https://doi.org/10.1108/HFF-11-2020-0743

I. Fazeli, M.R. Sarmasti Emami, A. Rashidi, Investigation and optimization of the behavior of heat transfer and flow of MWCNT-CuO hybrid nanofluid in a brazed plate heat exchanger using response surface methodology. Int. Commun. Heat Mass Transf. 122, 105175 (2021). https://doi.org/10.1016/j.icheatmasstransfer.2021.105175

A. Zamzamian, S.N. Oskouie, A. Doosthoseini, A. Joneidi, M. Pazouki, Experimental investigation of forced convective heat transfer coefficient in nanofluids of Al2O3/EG and CuO/EG in a double pipe and plate heat exchangers under turbulent flow. Exp. Therm. Fluid Sci. 35, 495–502 (2011). https://doi.org/10.1016/j.expthermflusci.2010.11.013

M.M. Elias, R. Saidur, N.A. Rahim, M.R. Sohel, I.M. Mahbubul, Performance investigation of a plate heat exchanger using nanofluid with different chevron angle. Adv. Mater. Res. 832, 254–259 (2014). https://doi.org/10.4028/www.scientific.net/AMR.832.254

A.K. Tiwari, P. Ghosh, J. Sarkar, H. Dahiya, J. Parekh, Numerical investigation of heat transfer and fluid flow in plate heat exchanger using nanofluids. Int. J. Therm. Sci. 85, 93–103 (2014). https://doi.org/10.1016/j.ijthermalsci.2014.06.015

A.K. Tiwari, P. Ghosh, J. Sarkar, Particle concentration levels of various nanofluids in plate heat exchanger for best performance. Int. J. Heat Mass Transf. 89, 1110–1118 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.118

M. Unverdi, Y. Islamoglu, Characteristics of heat transfer and pressure drop in a chevron-type plate heat exchanger with Al2O3/water nanofluids. Therm. Sci. 21, 2379–2391 (2017)

G.S. Prashant, T. Sarao, Experimental analysis of heat transfer and friction factor in plate heat exchanger with different or. Int. J. Eng. Trans. A Basics 29, 1450–1458 (2016). https://doi.org/10.5829/idosi.ije.2016.29.10a.16

Z. Taghizadeh-Tabari, S. Zeinali Heris, M. Moradi, M. Kahani, The study on application of TiO2/water nanofluid in plate heat exchanger. Renew. Sustain. Energy Rev. 58, 1318–1326 (2016). https://doi.org/10.1016/j.rser.2015.12.292

V. Kumar, A.K. Tiwari, S.K. Ghosh, Effect of variable spacing on performance of plate heat exchanger using nanofluids. Energy 114, 1107–1119 (2016). https://doi.org/10.1016/j.energy.2016.08.091

V. Kumar, A.K. Tiwari, S.K. Ghosh, Effect of chevron angle on heat transfer performance in plate heat exchanger using ZnO/water nanofluid. Energy Convers. Manag. 118, 142–154 (2016). https://doi.org/10.1016/j.enconman.2016.03.086

M.M. Sarafraz, F. Hormozi, Heat transfer, pressure drop and fouling studies of multi-walled carbon nanotube nano-fluids inside a plate heat exchanger, vol. 72 (Elsevier, Amsterdam, 2016)

D. Huang, Z. Wu, B. Sunden, Effects of hybrid nanofluid mixture in plate heat exchangers. Exp. Therm. Fluid Sci. 72, 190–196 (2016). https://doi.org/10.1016/j.expthermflusci.2015.11.009

M.M. Elias, R. Saidur, R. Ben-Mansour, A. Hepbasli, N.A. Rahim, K. Jesbains, Heat transfer and pressure drop characteristics of a plate heat exchanger using water based Al2O3 nanofluid for 30° and 60° chevron angles. Heat Mass Transf. Stoffuebertragung 54, 2907–2916 (2018). https://doi.org/10.1007/s00231-018-2335-1

M. Attalla, H.M. Maghrabie, An experimental study on heat transfer and fluid flow of rough plate heat exchanger using Al2O3/water nanofluid. Exp. Heat Transf. 33, 261–281 (2020). https://doi.org/10.1080/08916152.2019.1625469

B. Bansal, H. Müller-Steinhagen, X.D. Chen, Performance of plate heat exchangers during calcium sulphate fouling - investigation with an in-line filter. Chem. Eng. Process. Process Intensif. 39, 507–519 (2000). https://doi.org/10.1016/S0255-2701(00)00098-2

N. Andritsos, A.J. Karabelas, Calcium carbonate scaling in a plate heat exchanger in the presence of particles. Int. J. Heat Mass Transf. 46, 4613–4627 (2003). https://doi.org/10.1016/S0017-9310(03)00308-9

B. Bansal, Hans MÜller-Steinhage, Comparison of crystallization fouling in plate and double-pipe heat exchangers. Heat Transf. Eng. 22, 13–25 (2001). https://doi.org/10.1080/01457630117263

P. Sriyutha Murthy et al., Evaluation of sodium hypochlorite for fouling control in plate heat exchanger. Int. Biodeterior. Biodegrad. 55, 161–170 (2005). https://doi.org/10.1016/j.ibiod.2004.11.001

M.G. Mwaba, M.R. Golriz, J. Gu, A semi-empirical correlation for crystallization fouling on heat exchange surfaces. Appl. Therm. Eng. 26, 440–447 (2006). https://doi.org/10.1016/j.applthermaleng.2005.05.021

B. Bansal, X.D. Chen, H. Müller-Steinhagen, Analysis of ‘classical’ deposition rate law for crystallisation fouling. Chem. Eng. Process. Process Intensif. 47, 1201–1210 (2008). https://doi.org/10.1016/j.cep.2007.03.016

Y. Mahdi, A. Mouheb, L. Oufer, A dynamic model for milk fouling in a plate heat exchanger. Appl. Math. Model. 33, 648–662 (2009). https://doi.org/10.1016/j.apm.2007.11.030

A.B. Kananeh, E. Scharnbeck, U.D. Kück, N. Räbiger, Reduction of milk fouling inside gasketed plate heat exchanger using nano-coatings. Food Bioprod. Process. 88, 349–356 (2010). https://doi.org/10.1016/j.fbp.2010.09.010

C. Lei, Z. Peng, T. Day, X. Yan, X. Bai, C. Yuan, Experimental observation of surface morphology effect on crystallization fouling in plate heat exchangers. Int. Commun. Heat Mass Transf. 38, 25–30 (2011). https://doi.org/10.1016/j.icheatmasstransfer.2010.10.006

M.M. Abu-Khader, Plate heat exchangers: recent advances. Renew. Sustain. Energy Rev. 16, 1883–1891 (2012). https://doi.org/10.1016/j.rser.2012.01.009

C. Boxler, W. Augustin, S. Scholl, Composition of milk fouling deposits in a plate heat exchanger under pulsed flow conditions. J. Food Eng. 121, 1–8 (2014). https://doi.org/10.1016/j.jfoodeng.2013.08.003

M.M. Sarafraz, F. Hormozi, Convective boiling and particulate fouling of stabilized CuO-ethylene glycol nanofluids inside the annular heat exchanger. Int. Commun. Heat Mass Transf. 53, 116–123 (2014). https://doi.org/10.1016/j.icheatmasstransfer.2014.02.019

Z.T. Tabari, S.Z. Heris, Heat transfer performance of milk pasteurization plate heat exchangers using MWCNT/water nanofluid. J. Dispers. Sci. Technol. 36, 196–204 (2015). https://doi.org/10.1080/01932691.2014.894917

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Singh, S.K. & Sharma, D. A Comprehensive Review on Thermal Performance Enhancement of Plate Heat Exchanger. Int J Thermophys 43, 109 (2022). https://doi.org/10.1007/s10765-022-03036-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-022-03036-7