Abstract

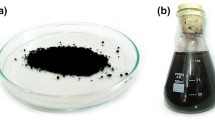

Use of oscillating heat pipes as a new component related to heat transfer has always been of interest for different technologies in recent years. A novel U-shaped structure is designed for the 3D-PHPs and this novel design creates a high performance device. In this experimental study, the thermal performance of a newly designed three-dimensional pulsating heat pipe with Fe3O4 nanofluid exposed to magnetic field under different heat inputs (0 W to 450 W). The results showed that the filling ratio of 50 % had better thermal performance. Our results indicated that the use of iron oxide nanofluid (Fe3O4) at 2 % mass concentration significantly improves the thermal performance of the pulsating heat pipe especially in 50 % filling ratio compared to pure water, which also showed that the improvement of heat transfer coefficient can be better by using corrugated evaporator under magnetic field. The results show that when the evaporator of 3D-PHP is exposed to a constant magnetic field, the thermal performance of the device improves significantly. The results showed that thermal resistance has been reduced 18 %, 20 %, and 25 %, respectively, for nanofluid with 50 % filling ratio and corrugated evaporator and under magnetic field compared to water. Compared to pure water operating fluid, application of nanofluid, magnetic field, and corrugated evaporator reduces the average heat resistance and increases the heat transfer coefficient. This investigation will promote the development of effective cooling for electronic devices.

Similar content being viewed by others

Abbreviations

- A:

-

Area (m2)

- B:

-

Magnetic flux density (Tesla or Gauss)

- D:

-

Diameter (mm)

- I:

-

Electric current (A)

- \(q^{\prime\prime}\) :

-

Heat flux (W·m−2)

- q:

-

Heating power (W)

- h:

-

Heat transfer coefficient (W·m−2·K−1)

- L:

-

Length (m)

- T:

-

Temperature (°C)

- R:

-

Thermal resistance (°C·W−1)

- V:

-

Voltage (V)

- Ŋ:

-

Efficiency (%)

- Δ:

-

Uncertainty

- ρ:

-

Density (kg·m−3)

- FR:

-

Filling ratio

- PHP:

-

Pulsating heat pipe

- ad:

-

Adiabatic

- c:

-

Condenser

- e:

-

Evaporator

- i:

-

Inner

- in:

-

Input

- out:

-

Output

- sat:

-

Saturation

References

Akachi H, United States Patent: 4921041—Structure of a Heat Pipe (1990)

C. Wilson, B. Borgmeyer, R.A. Winholtz, H.B. Ma, D.L. Jacobson, D.S. Hussey, Visual observation of oscillating heat pipes using neutron radiography. J. Thermophys. Heat Transf. 22, 366–372 (2008). https://doi.org/10.3390/app6110321

S. Khandekar, P. Charoensawan, M. Groll, P. Terdtoon, Closed loop pulsating heat pipes. Part B: visualization and semi-empirical modeling. Appl. Therm. Eng. 23, 2021–2033 (2003). https://doi.org/10.1016/S1359-4311(03)00168-6

H.B. Ma, B. Borgmeyer, P. Cheng, Y. Zhang, Heat transport capability in an oscillating heat pipe. J. Heat Transf. 130, 081501–081507 (2008). https://doi.org/10.1186/1556-276X-6-296

S. Rittidech, P. Terdtoon, M. Murakami, P. Kamonpet, W. Jompakdee, Correlation to predict heat transfer characteristics of a closed-end oscillating heat pipe at normal operating condition. Appl. Therm. Eng. 23, 497–510 (2003). https://doi.org/10.1016/S1359-4311(02)00215-6

W. Qu, H. Ma, Theoretical analysis of startup of a pulsating heat pipe. Int. J. Heat Mass Transf. 50, 2309–2316 (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2006.10.043

Y.Z. Ling, X.S. Zhang, F. Wang, X.H. She, Performance study of phase change materials coupled with three dimensional oscillating heat pipes with different structures for electronic cooling. Renew. Energy 154, 636–649 (2020). https://doi.org/10.1016/j.renene.2020.03.008

C.Y. Tseng, K.S. Yang, C.C. Wang, Non-uniform three-dimensional pulsating heat pipe for anti-gravity high-flux applications. Int. J. Energy. 13, 3068 (2020). https://doi.org/10.3390/en13123068

J. Qu, J. Zhao, Z. Rao, Experimental investigation on the thermal performance of three dimensional oscillating heat pipe. Int. J. Heat Mass Transf. 109, 589–600 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.02.040

Y. He, D. Jiao, G. Pei, X. Hu, L. He, Experimental study on a three-dimensional pulsating heat pipe with tandem tapered nozzles. Exp. Therm. Fluid Sci. (2020). https://doi.org/10.1016/j.expthermflusci.2020.110201

B. Borgmeyer, C. Wilson, R.A. Winholtz, H.B. Ma, D. Jacobson, D. Hussey, Heat transport capability and fluid flow neutron radiography of three-dimensional oscillating heat pipes. J. Heat Transf. 132, 061502–061511 (2010). https://doi.org/10.1115/1.4000750

T. Hao, H. Ma, X. Ma, Heat transfer performance of polytetrafluoroethylene oscillating heat, pipe with water, ethanol, and acetone as working fluids. Int. J. Heat Mass Transf. 131, 109–120 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2018.08.133

E. Sadeghinezhad, M. Mehrali, M.A. Rosen, A.R. Akhiani, S.T. Latibari, M. Mehrali, H.C. Metselaar, Experimental investigation of the effect of graphene nanofluids on heat pipe thermal performance. Appl. Therm. Eng. 100, 775–787 (2016). https://doi.org/10.1016/j.applthermaleng.2016.02.071

D. Yin, H. Rajab, H.B. Ma, Theoretical analysis of maximum filling ratio in an oscillating heat pipe. Int. J. Heat Mass Transf. 74, 353–357 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2014.03.018

P. Wang, X. Cui, J. Weng, Z. Cai, R. Cai, Experimental investigation of the heat transfer performance of an oscillating heat pipe with LiCl salt solution. Int. J. Heat Mass Transf. 158, 120033 (2020). https://doi.org/10.1016/j.ijheatmasstransfer.2020.120033

H. Peng, P.F. Pai, H. Ma, Nonlinear thermomechanical finite-element modeling, analysis and characterization of multi-turn oscillating heat pipes. Int. J. Heat Mass Transf. 69, 424–437 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2013.10.041

Y. Ji, M. Wu, Y. Feng, C. Yu, L. Chu, C. Chang, Y. Li, X. Xiao, H. Ma, An experimental investigation on the heat transfer performance of a liquid metal high-temperature oscillating heat pipe. Int. J. Heat Mass Transf. 149, 119198 (2020). https://doi.org/10.1016/j.ijheatmasstransfer.2019.119198

H.R. Goshayeshi, M. Goodarzi, M.R. Safaei, M. Dahari, Experimental study on the effect of inclination angle on heat transfer enhancement of a ferrofluid in a closed loop oscillating heat pipe under magnetic field. Exp. Therm. Fluid Sci. 74, 265–270 (2016). https://doi.org/10.1016/j.expthermflusci.2016.01.003

T. Yousefi, S. Mousavi, B. Farahbakhsh, M. Saghir, Experimental investigation on the performance of CPU coolers: effect of heat pipe inclination angle and the use of nanofluids. Microelectron. Reliab. 53, 1954–1961 (2013). https://doi.org/10.1016/j.microrel.2013.06.012

S. Yanxi, X. Jinliang, Chaotic behavior of pulsating heat pipes. Int. J. Heat Mass Transf. 52, 2932–2941 (2009). https://doi.org/10.1016/j.ijheatmasstransfer.2009.02.030

H.R. Goshayeshi, M.R. Safaei, M. Goodarzi, M. Dahari, Particle size and type effects on heat transfer enhancement of ferro-nanofluids in a pulsating heat pipe. J. Powder Technol. 301, 1218–1226 (2016). https://doi.org/10.1016/j.powtec.2016.08.007

D.A. Reay, P.A. Kew, R.J. McGlen, Chapter 6—Special Types of Heat Pipe, Heat Pipes: Theory, Design and Applications (Butterworth-Heinemann, Oxford, 2014), pp. 135–173

Y. Ji, G. Liu, H. Ma, G. Li, Y. Sun, An experimental investigation of heat transfer performance in a polydimethylsiloxane (PDMS) oscillating heat pipe. Appl. Therm. Eng. 61, 690–697 (2013). https://doi.org/10.1016/j.applthermaleng.2013.09.001

E. Sedighi, A. Amarloo, B. Shafii, Numerical and experimental investigation of flat-plate pulsating heat pipes with extra branches in the evaporator section. Int. J. Heat Mass Transf. 126, 431–441 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.05.047

H. Yang, S. Khandekar, M. Groll, Performance characteristics of pulsating heat pipes as integral thermal spreaders. Int. J. Therm. Sci. 48, 815–824 (2009). https://doi.org/10.1016/j.ijthermalsci.2008.05.017

R. Senjaya, T. Inoue, Oscillating heat pipe simulation considering bubble generation. Part I: Presentation of the model and effects of a bubble generation. Int. J. Heat Mass Transf. 60, 816–824 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2013.01.059

H.R. Goshayeshi, I. Chaer, Experimental study and flow visualization of Fe2O3/kerosene in glass oscillating heat pipes. Appl. Therm. Eng. 103, 1213–1218 (2016). https://doi.org/10.1016/j.applthermaleng.2016.04.109

H. Xian, W. Xu, Y. Zhang, X. Du, Y. Yang, Thermal characteristics and flow patterns of oscillating heat pipe with pulse heating. Int. J. Heat Mass Transf. 79, 332–341 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2014.08.002

S. Ahangar Zonouzi, R. Khodabandeh, H. Safarzadeh, H. Aminfar, Y. Trushkina, M. Mohammadpourfard, M. Ghanbarpour, A.G. Salazar, Experimental investigation of the flow and heat transfer of magnetic nanofluid in a vertical tube in the presence of magnetic quadrupole field. Exp. Therm. Fluid Sci. 91, 155 (2018). https://doi.org/10.1016/j.expthermflusci.2017.10.013

L. Sha, Y. Ju, H. Zhang, The influence of the magnetic field on the convective heat transfer characteristics of Fe3O4/water nanofluids. Appl. Therm. Eng. 126, 108–116 (2017). https://doi.org/10.1016/j.applthermaleng.2017.07.150

E. Esmaeili, R. Ghazanfar, S.A. Rounagh, The influence of the alternating magnetic field on the convective heat transfer properties of Fe3O4-containing nanofluids through the Neel and Brownian mechanisms. Appl. Therm. Eng. 110, 1212–1219 (2017). https://doi.org/10.1016/j.applthermaleng.2016.09.014

S.W. Kang, Y.C. Wang, Y.C. Liu, H.M. Lo, Visualization and thermal measurement for magnetic nanofluid pulsating heat pipe. Appl. Therm. Eng. 126, 1044–1050 (2017). https://doi.org/10.1016/j.applthermaleng.2017.02.051

H.R. Goshayeshi, Effect of a magnetic field at inclination n angles on the performance of copper oscillating g heat pipes. Int. J. Energy Clean Environ. 16, 1–11 (2015). https://doi.org/10.1615/InterJEnerCleanEnv.2016015686

H. Davari, H.R. Goshayeshi, H.F. Oztop, I. Chaer, Experimental investigation of oscillating heat pipe efficiency for a novel condenser by using Fe3O4 nanofluid. J. Therm. Anal. Calorim. 140, 2605–2614 (2020). https://doi.org/10.1007/s10973-019-09032-8

E. Sadeghinezhad, M. Mehrali, A. Akhiani, D.A. Latibari, H. Simon, C. Metselaar, M. Mehrali, Experimental study on heat transfer augmentation of graphene based ferrofluids in presence of magnetic field. Appl. Therm. Eng. 114, 415–427 (2017). https://doi.org/10.1016/j.applthermaleng.2016.11.199

M. Ashouri, B. Ebrahimi, M.B. Shafii, M.H. Saidi, M.S. Saidi, Correlation for Nusselt number in pure magnetic convection ferrofluid flow in a square cavity by a numerical investigation. Magn. Magn. Mater. 322, 3607–3613 (2010). https://doi.org/10.1016/j.jmmm.2010.05.041

J. Wang, H. Ma, Q. Zhu, Y. Dong, K. Yue, Numerical and experimental investigation of pulsating heat pipes with corrugated configuration. Appl. Therm. Eng. 102, 158–166 (2016). https://doi.org/10.1016/j.applthermaleng.2016.03.163

M. Mehrali, E. Sadeghinezhad, R. Azizian, A.R. Akhiani, S.T. Latibari, M. Mehrali, H.S.C. Metselaar, Effect of nitrogen-doped graphene nanofluid on the thermal performance of the grooved copper heat pipe. Energy Convers. Manage. 118, 459–473 (2016). https://doi.org/10.1016/j.enconman.2016.04.028

F. Fadaei, M. Shahrokhi, A. Molaei Dehkordi, Z. Abbasi, Heat transfer enhancement of Fe3O4 ferrofluids in the presence of magnetic field. J. Magn. Magn. Mater. 01, 46 (2017). https://doi.org/10.1016/j.jmmm.2017.01.046

N.S. Pandya, A.N. Desai, A.K. Tiwari, Z. Said, Influence of the geometrical parameters and particle concentration levels of hybrid nanofluid on the thermal performance of axial grooved heat pipe. Therm. Sci. Eng. Prog. (2020). https://doi.org/10.1016/j.tsep.2020.100762

J. Wang, G. Li, H. Zhu, J. Luo, B. Sundén, Experimental investigation on convective heat transfer of ferrofluids inside a pipe under various magnet orientations. Int. J. Heat Mass Transf. 132, 407–419 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2018.12.023

H.R. Goshayeshi, F. Izadi, K. Bashirnezhad, Comparison of heat transfer performance on closed pulsating heat pipe for Fe3O4 and γFe2O3 for achieving an empirical correlation. Physica E 89, 43–49 (2017). https://doi.org/10.1016/j.physe.2017.01.014

J. Holman, Heat Transfer, 8th edn. (McGraw-Hill Inc., New York, 2001)

Q. Jie, Z. Jiateng, R. Zhonghao, Experimental investigation on the thermal performance of three dimensional oscillating heat pipe. Int. J. Heat Mass Transf. 109, 589–600 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.02.040

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alizadeh Jajarm, A.R., Goshayeshi, H.R. & Bashirnezhad, K. Experimental Study of Thermal Performance of a Newly Designed Pulsating Heat Pipe with Fe3O4 Nanofluid-Exposed Magnetic Field and Corrugated Evaporator. Int J Thermophys 43, 40 (2022). https://doi.org/10.1007/s10765-021-02971-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-021-02971-1