Abstract

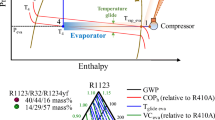

R134a, commonly used for automotive air conditioning, will be phased out due to its high global warming potential, while R1234yf/R290 and R1234yf/R600a were considered as two potential alternatives owing to their excellent environmental characteristics. In this work, the thermophysical properties and cycle performances of the above refrigerants were investigated. The vapor–liquid equilibrium predicted models for R1234yf/R290 and R1234yf/R600a were constructed using SRK, PR equations of state combined with vdW, HV mixing rules, respectively, and the results presented that all four models could describe the vapor–liquid equilibrium characteristics of mixtures well. Among them, the model of PR equation combined with HV mixing rule had the highest accuracy, with the average absolute relative deviations of 0.1% and 0.21% for pressures, and the average absolute deviations of 0.0012 and 0.0027 for vapor-phase mole fractions, respectively. R1234yf/R290 and R1234yf/R600a mixtures exhibited the near azeotropic properties at the molar fractions of R1234yf near 0.3 and 0.85, respectively. Then, the enthalpy and entropy calculation models of R1234yf/R290 (0.3/0.7) and R1234yf/R600a (0.85/0.15) were developed in combination with the residual properties. Finally, the cycle performances of mixtures were analyzed, and the present results suggested that the cycle performance of R1234yf/R290 (0.3/0.7) was better than that of R1234yf/R600a (0.85/0.15), R1234yf, and R134a which could provide the basic thermophysical parameters and theoretical basis for the search of alternative refrigerants to R134a in automotive air conditioning systems.

Similar content being viewed by others

Abbreviations

- a :

-

Energy parameter (Pa·cm6·mol−2)

- b :

-

Co-volume parameter (cm3·mol−1)

- c p :

-

Isobaric specific heat capacity (kJ·kg−1·K−1)

- COP:

-

Coefficient of performance

- f :

-

Free energy (kJ·kg−1)

- \(g^{E}_{\infty }\) :

-

Excess Gibbs’ energy at infinite pressure

- h :

-

Specific enthalpy (kJ·kg−1)

- HV:

-

Huron-Vidal

- k ij :

-

Binary interaction parameter

- M :

-

Mole molecule mass (g·mol−1)

- N :

-

Number of experimental data

- NRTL:

-

Non-random two-liquid

- P :

-

Pressure (MPa)

- PR:

-

Peng-Robinson

- q m :

-

Specific refrigeration capacity (kJ·kg−1)

- q v :

-

Volumetric refrigeration capacity (kJ·m−3)

- R:

-

Universal gas constant (J·mol−1·K−1)

- s :

-

Specific entropy (kJ·kg−1·K−1)

- SRK:

-

Soave–Redlich–Kwong

- T :

-

Temperature (K)

- v :

-

Molar volume (cm3·mol−1)

- vdW:

-

Van der Waals

- VLE:

-

Vapor–liquid equilibrium

- w :

-

Specific power consumption (kJ·kg−1)

- X :

-

Mass fraction

- x :

-

Molar fraction of liquid phase

- y :

-

Molar fraction of vapor phase

- α ij :

-

NRTL model parameter

- γ :

-

Compression ratio

- ρ :

-

Density (kg·m−3)

- τ ij :

-

Binary interaction parameter of NRTL model

- ω :

-

Acentric factor

- bub:

-

Bubble point

- c:

-

Critical

- cal:

-

Calculated

- com:

-

Compressor

- con:

-

Condenser

- dew:

-

Dew point

- dis:

-

Discharge

- eva:

-

Evaporator

- exp:

-

Experimental

- i, j :

-

Component index

- id:

-

Ideal state

- in:

-

Inlet

- l:

-

Liquid

- m:

-

Mixture

- max:

-

Maximum

- out:

-

Outlet

- R:

-

Contrast state

- r:

-

Residual

- ref:

-

The data are taken from REFPROP 9.1

- v:

-

Vapor

References

B.O. Bolaji, Z. Huan, Renew. Sustain. Energy Rev. 18, 49–54 (2013). https://doi.org/10.1016/j.rser.2012.10.008

S.A. Montzka, M. McFarland, S.O. Andersen, B.R. Miller, D.W. Fahey, B.D. Hall, L. Hu, C. Siso, J.W. Elkins, J. Phys. Chem. A. 119, 4439–4449 (2015). https://doi.org/10.1021/jp5097376

I.H. Bell, P.A. Domanski, M.O. McLinden, G.T. Linteris, Int. J. Refrig. 104, 485–495 (2019). https://doi.org/10.1016/j.ijrefrig.2019.05.035

S. Devotta, A.V. Waghmare, N.N. Sawant, B.M. Domkundwar, Appl. Therm. Eng. 21, 703–715 (2001). https://doi.org/10.1016/S1359-4311(00)00079-X

Y. Shin, T. Kim, A. Lee, H. Cho, Entropy 22, 1 (2019). https://doi.org/10.3390/e22010004

Z. Meng, H. Zhang, M. Lei, Y. Qin, J. Qiu, Int. J. Heat Mass Transfer 116, 362–370 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.049

R.K. Gaurav, Mater. Today: Proc. 4, 112–118 (2017). https://doi.org/10.1016/j.matpr.2017.01.003

J.K. Vaghela, Energy Proc. 109, 153–160 (2017). https://doi.org/10.1016/j.egypro.2017.03.083

H. Cho, H. Lee, C. Park, Appl. Therm. Eng. 61, 563–569 (2013). https://doi.org/10.1016/j.applthermaleng.2013.08.030

Y. Lee, D. Jung, Appl. Therm. Eng. 35, 240–242 (2012). https://doi.org/10.1016/j.applthermaleng.2011.09.004

S. Daviran, A. Kasaeian, S. Golzari, O. Mahian, S. Nasirivatan, S. Wongwises, Appl. Therm. Eng. 110, 1091–1100 (2017). https://doi.org/10.1016/j.applthermaleng.2016.09.034

Y. Zhang, C. Liu, T. Wang, L. Pan, W. Li, J. Shi, J. Chen, Int. J. Refrig. 110, 286–294 (2020). https://doi.org/10.1016/j.ijrefrig.2019.11.001

I. Sarbu, Int. J. Refrig. 46, 123–141 (2014). https://doi.org/10.1016/j.ijrefrig.2014.04.023

T.S. Ravikumar, D. Mohan Lal, Energy Convers. Manag. 50, 1891–1901 (2009). https://doi.org/10.1016/j.enconman.2009.04.027

K.A. Joudi, A.S.K. Mohammed, M.K. Aljanabi, Energy Convers. Manag. 44, 2959–2976 (2003). https://doi.org/10.1016/s0196-8904(03)00051-7

Q. Zhong, X. Dong, Y. Zhao, H. Li, H. Zhang, H. Guo, M. Gong, Int. J. Refrig. 81, 26–32 (2017). https://doi.org/10.1016/j.ijrefrig.2017.05.016

Q. Zhong, X. Dong, H. Zhang, H. Li, M. Gong, J. Shen, J. Wu, J. Chem. Thermodyn. 107, 126–132 (2017). https://doi.org/10.1016/j.jct.2016.12.029

Y. Chen, Z. Yang, R. Rui, B. Feng, Z. Lv, W. Zhao, Y. Ge, CIESC Journal 70, 3248–3255 (2019)

P. Hu, L.X. Chen, Z.S. Chen, Fluid Phase Equilib. 365, 1–4 (2014). https://doi.org/10.1016/j.fluid.2013.12.015

H. Zhang, H. Li, B. Gao, Q. Zhong, W. Wu, W. Liu, X. Dong, M. Gong, E. Luo, Int. J. Refrig. 95, 28–37 (2018). https://doi.org/10.1016/j.ijrefrig.2018.07.029

A. Saeed, S. Ghader, Fluid Phase Equilib. 493, 10–25 (2019). https://doi.org/10.1016/j.fluid.2019.03.027

X. Chen, H. Li, Fluid Phase Equilib. 528, 112852 (2021). https://doi.org/10.1016/j.fluid.2020.112852

N.G. Tassin, V.A. Mascietti, M. Cismondi, Fluid Phase Equilib. 480, 53–65 (2019). https://doi.org/10.1016/j.fluid.2018.10.005

M. Ghanbari, M. Ahmadi, A. Lashanizadegan, Cryogenics 84, 13–19 (2017). https://doi.org/10.1016/j.cryogenics.2017.04.001

G. Soave, S. Gamba, L.A. Pellegrini, Fluid Phase Equilib. 299, 285–293 (2010). https://doi.org/10.1016/j.fluid.2010.09.012

X. Yao, L. Ding, X. Dong, Y. Zhao, X. Wang, J. Shen, M. Gong, Int. J. Refrig. 120, 97–103 (2020). https://doi.org/10.1016/j.ijrefrig.2020.09.008

G. Soave, Chem. Eng. Sci. 27, 1197–1203 (1972). https://doi.org/10.1016/0009-2509(72)80096-4

D.Y. Peng, D.B. Robinson, Ind. Eng. Chem. Res. 15, 59–64 (1976). https://doi.org/10.1021/i160057a011

E.W. Lemmon, M.O. Mclinden, M.L. Huber, Reference Fluid Thermodynamic and Transport Properties (REFPROP), NIST Standard Reference Database 23, Version 9.1 (2013).

D.S.H. Wong, S.I. Sandler, AIChE J. 38, 671–680 (1992). https://doi.org/10.1002/aic.690380505

H.J. Vidal, Fluid Phase Equilib. 3, 255–271 (1979). https://doi.org/10.1016/0378-3812(79)80001-1

H. Renon, J.M. Prausnitz, AIChE J. 14, 135–144 (1968). https://doi.org/10.1002/aic.690140124

B.B. Yu, H.S. Ouyang, J.Y. Shi, W.C. Liu, J.P. Chen, Int. J. Refrig. 121, 95–104 (2021). https://doi.org/10.1016/j.ijrefrig.2020.09.018

N.A. Lai, Appl. Therm. Eng. 70, 1–6 (2014). https://doi.org/10.1016/j.applthermaleng.2014.04.042

R. Wang, X. Zhang, J. Hu, J. Ma, Y. Shang, Refrig. Air-Cond. 19, 18–21 (2019)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 22068024).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, N., Li, B., Feng, L. et al. Research on the Thermophysical Properties and Cycle Performances of R1234yf/R290 and R1234yf/R600a. Int J Thermophys 42, 123 (2021). https://doi.org/10.1007/s10765-021-02875-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-021-02875-0