Abstract

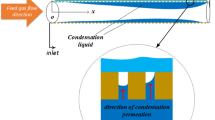

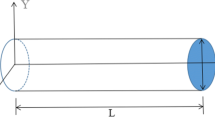

Nanoporous tubular ceramic membranes (TCMs) are commonly used to extract water vapor and to recover latent heat from flue gas in thermal power plants. Water vapor condenses on the surface of the outer wall of the TCM, and the generated condensate permeates the membrane and flows along with the coolant water within the membrane. With time and use, fouling cakes will gradually accumulate and adhere on the inner surface of the membrane wall because of different kinds of soluble salts in the coolant water, which have negative effects on the water recovery performance of the membrane. This paper describes experiments to analyze the effect of membrane use times (0 h, 400 h and 800 h) on fouling cakes. The water recovery performance of the membrane with different use times is investigated experimentally and numerically using the commercial software FLUENT 14.5. Lastly, we evaluate the significance of multiple operational conditions on the water recovery process of ceramic membranes by using an ANOVA based on both the experimental and numerical results. The results showed that the water recovery rate of the membrane decreased by a maximum of 76.3 % when its use time reached 800 h. Furthermore, the original water vapor content of the gas plays a more critical role on the water recovery process compared to other operational parameters.

Similar content being viewed by others

Abbreviations

- A :

-

Area of cells in the near-wall region (m2)

- V :

-

Volume of cells in the near-wall region (m3)

- P :

-

Static pressure (Pa)

- T :

-

Temperature (K)

- r :

-

Radius (m)

- U :

-

velocity magnitude (m·s−1)

- D :

-

Diffusion coefficient (m2·s−1)

- S :

-

Source term

- l :

-

Length of the ceramic tube (m)

- t :

-

Time step (s)

- Δt :

-

Using time (h)

- M :

-

Mass content (kg)

- m :

-

Mass flux (kg·m−2·s−1)

- Kn :

-

Kuhn number

- h :

-

Convective heat transfer coefficient (W·m−2·K−1)

- q :

-

Heat flux (kJ·m−2·s−1)

- x :

-

Distance along the ceramic tube (mm)

- k B :

-

Boltzmann constant

- k 0 :

-

Permeability coefficient

- W :

-

Mass fraction

- mass :

-

Continuity equation

- m :

-

Membrane

- vap :

-

Vapor

- non :

-

Noncondensable gas

- sat :

-

Saturated state of flow

- species :

-

Species conversation equation

- enr :

-

Energy conversation equation

- rec :

-

Water recovery

- a :

-

Average

- b :

-

Bulk

- c :

-

Coolant water

- f :

-

Fouling cake

- wall :

-

Near-wall region

- 0:

-

Original state

- ρ :

-

Density (kg·m−3)

- τ :

-

Tortuosity of pores

- γ :

-

Latent heat (kJ·kg−1)

- ε :

-

Dissipation rate

- k :

-

Turbulent kinetic energy

- λ :

-

Thermal conductivity (W·m−1·K−1)

- µ :

-

Dynamic viscosity (Pa·s−1)

- σ :

-

Characteristic size of the gas mixture (nm)

- Φ :

-

Porosity

- f :

-

Friction factor for ceramic tubes

- δ :

-

Diffusion layer thickness

- φ :

-

Suction effect coefficient

References

D.S. Karousos, A.I. Labropoulos, A. Sapalidis et al., Nanoporous ceramic supported ionic liquid membranes for CO2, and SO2, removal from flue gas. Chem. Eng. J. 313, 777–790 (2017)

F. Asfand, Y. Stiriba, M. Bourouis, CFD simulation to investigate heat and mass transfer processes in a membrane-based absorber for water-LiBr absorption cooling systems. Energy 91, 517–530 (2015)

Y. Zhou, H. Chen, T. Xie et al., Effect of mass transfer on heat transfer of microporous ceramic membranes for water recovery. Int. J. Heat Mass Transf. 112, 643–648 (2017)

T. Loimer, Linearized description of the non-isothermal flow of a saturated vapor through a micro-porous membrane. J. Membr. Sci. 301, 107–117 (2007)

A. Behrang, P. Mohammadmoradi, S. Taheri et al., A theoretical study on the permeability of tight media; effects of slippage and condensation. Fuel 181, 610–617 (2016)

A. Bao, D. Wang, C.X. Lin, Nanoporous membrane tube condensing heat transfer enhancement study. Int. J. Heat Mass Transf. 84, 456–462 (2015)

H.W. Hu, G.H. Tang, D. Niu, Wettability modified nanoporous ceramic membrane for simultaneous residual heat and condensate recovery. Sci Rep 6, 27274 (2016)

Y. Zhang, A. Faghri, M.B. Shafii, Capillary blocking in forced convective condensation in horizontal miniature channels. J. Heat Transf. 123, 642–653 (2001)

G. Caruso, D.V.D. Maio, Heat and mass transfer analogy applied to condensation in the presence of noncondensable gases inside inclined tubes. Int. J. Heat Mass Transf. 68, 401–414 (2014)

W. Liu, H. Jia, Z.C. Liu et al., The approach of minimum heat consumption and its applications in convective heat transfer optimization. Int. J. Heat Mass Transf. 57, 389–396 (2013)

P. Uchytil, T. Loimer, Large mass flux differences for opposite flow directions of a condensable gas through an asymmetric porous membrane. J. Membr. Sci. 470, 451–457 (2014)

Jun-De Li, CFD simulation of water vapour condensation in the presence of; non-condensable gas in vertical cylindrical condensers. Int. J. Heat Mass Transf. 57, 708–721 (2013)

L. Vyskocil, J. Schmid, J. Macek, CFD simulation of air–steam flow with condensation. Nucl. Eng. Des. 279, 147–157 (2014)

M. Nazarimanesh, T. Yousefi, M. Ashjaee, Experimental study on the effects of inclination situation of the sintered heat pipe on its thermal performance. Exp. Therm. Fluid Sci. 68, 625–633 (2015)

S.A. Bahrani, J.Y. Monteau, S.A. Rezzoug et al., Physics-based modeling of simultaneous heat and mass transfer intensification during vacuum steaming processes of starchy material. Chem. Eng. Process. 85, 216–226 (2014)

M. Yang, D. Yu, M. Liu et al., Optimization of MBR hydrodynamics for cake layer fouling control through CFD simulation and RSM design. Bioresour. Technol. 227, 102 (2016)

M. Esawy, M.R. Malayeri, Modeling of CaSO4, crystallization fouling of finned tubes during nucleate pool boiling. Chem. Eng. Res. Des. 118, 51–60 (2017)

W. Zhang, X. Ruan, Y. Ma et al., Modeling and simulation of mitigating membrane fouling under a baffle-filled turbulent flow with permeate boundary. Sep. Purif. Technol. 179, 13–24 (2017)

S.M. Alsadaie, I.M. Mujtaba, Dynamic modelling of heat exchanger fouling in multistage flash (MSF) desalination. Desalination 409, 47–65 (2017)

A.K. Sadaghiani, M. Yildiz, A. Koşar, Numerical modeling of convective heat transfer of thermally developing nanofluid flows in a horizontal microtube. Int. J. Therm. Sci. 109, 54–69 (2016)

W. Zhang, J. Ma, P. Wang et al., Investigations on the interfacial capacitance and the diffusion boundary layer thickness of ion exchange membrane using electrochemical impedance spectroscopy. J. Membr. Sci. 502, 37–47 (2016)

J.J. Liu, Z.C. Liu, W. Liu, 3D numerical study on shell side heat transfer and flow characteristics of rod-baffle heat exchangers with spirally corrugated tubes. Int. J. Therm. Sci. 89, 34–42 (2015)

Funding

The authors are grateful for the supports of “Nation Key R&D Program of China” (Grant No. 2018YFB0604302).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and Animal Rights

This article does not contain any studies performed by any of the authors.

Informed Consent

Informed consent was obtained from all individual participants included in the study.

Rights and permissions

About this article

Cite this article

Yang, B., Chen, H., Ye, C. et al. Experimental and Numerical Simulation to Investigate the Effects of Membrane Fouling on the Heat and Mass Transfer. Int J Thermophys 40, 8 (2019). https://doi.org/10.1007/s10765-018-2471-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-018-2471-3