Abstract

Capillary tube expansion devices are widely used in refrigeration equipment; nevertheless, the mechanism of the flow is still not fully described and understood, so the experimental verification of most predictions is still necessary. A modified numerical model of capillary flow has been developed both for standard refrigerants and with emphasis for saturated fluorocarbon (C2F2n+2) refrigerants. These refrigerants have several unique properties (high dielectric performance, chemical stability, and radiation resistance). Therefore, they can be used in some special applications, where other common fluids cannot be applied. The main aim of this study was to prepare a practical capillary flow model, which would improve the procedure of predicting the behavior of capillary tubes for cooling circuits of particle detectors being built at the international CERN laboratory in Geneva. The generated numerical model was verified through available data from the literature and also via measurements performed in a real cooling circuit with pure, oil-free octafluoropropane (C3F8) refrigerant.

Similar content being viewed by others

Abbreviations

- c p :

-

Specific heat (J · kg−1 · K−1)

- e :

-

Specific energy (e = h + v 2/2 = E + p/ρ) (J · kg−1)

- f :

-

Friction factor

- h :

-

Enthalpy (J · kg−1)

- \(\mathop m\limits^{\bullet}\) :

-

Mass flow rate (kg · s−1)

- p :

-

Pressure (Pa)

- q :

-

Heat flux (W · m−2)

- s :

-

Entropy (J · kg−1 · K−1)

- t :

-

Time (s)

- v :

-

Velocity (m · s−1)

- z :

-

Axial coordinate (m)

- A :

-

Capillary inner cross section (m2)

- E :

-

Energy (sum of internal energy and kinetic energy) (J · kg−1)

- ID :

-

Inner diameter (m)

- K z :

-

Body forces (gravity) (m · s−2)

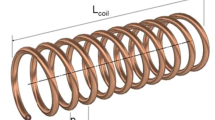

- L :

-

Capillary tube length (m)

- P :

-

Capillary inner perimeter (m)

- Re :

-

Reynolds number

- S :

-

Slip ratio

- T :

-

Temperature (K)

- α :

-

Void fraction

- δ :

-

Capillary wall roughness (m)

- ρ :

-

Density (kg · m−3)

- τ :

-

Shear stress (Pa)

- x :

-

Vapor quality

- Δz :

-

Control volume length (m)

- ΦLO :

-

Two-phase multiplier

- amb:

-

Ambient

- crit:

-

Critical flow conditions

- dis:

-

Discharge—conditions at capillary outlet

- evap:

-

Evaporation

- i :

-

Control volume inlet (point i of the computational grid)

- i + 1:

-

Control volume outlet (point i + 1 of the computational grid)

- in:

-

Capillary inlet

- sat:

-

Saturation properties

- TP:

-

Two-phase

- w:

-

Condition at the capillary inner wall

- g:

-

Vapor phase

- l:

-

Liquid phase

- –:

-

Arithmetical average over a control volume

- ~:

-

Integral average over a control volume

References

Mikol E.P. (1963) J. ASHRAE 75–86

Li R.Y., Lin S., Chen Z.Y., Chen Z.H. (1990) Int. J. Refrig. 13, 181

Chen Z.H., Li R.Y., Lin S., Chen Z.Y. (1990) ASHRAE Trans. 96, 550

Lackme C. (1979) Int. J. Multiphase Flow 5, 131

Koizumi H., Yokoyama K. (1980) ASHRAE Trans. 86, 19

Bansal P.K., Rupasinghe A.S. (1998) Appl. Therm. Eng. 18, 207

Kritsadathikarn P., Songnetichaovalit T., Lokathada N. (2002) Res. Article, Sci. Asia 28, 71

Sami S.M., Tribes C. (1998) Appl. Therm. Eng. 18, 491

Wong T.N., Ooi K.T. (1996) Appl. Therm. Eng. 16, 625

Z.L. Miropolskiy, R.I. Shneyerova, A.I. Karamysheva, in International Heat Transfer Conference, vol. 5 (Paris, 1970), Paper B 4.7

Lin S., Kwok C.C.K., Li R.Y., Chen Z.H., Chen Z.Y. (1991) Int. J. Multiphase Flow 17, 95

Wongwises S., Chan P. (2000) Int. Comm. Heat Transfer 27, 343

Bansal P.K., Wang G. (2004) Appl. Therm. Eng. 24, 851

Sinpiboon J., Wongwises S. (2002) Appl. Therm. Eng. 22, 2015

Escanes F., Pérez-Segarra C.D., Oliva A. (1995) Int. J. Refrig. 18, 113

Gnielinski V. (1976) Int. Chem. Eng. 16, 359

García-Valladares O., Pérez-Segarra C.D., Oliva A. (2002) Appl. Therm. Eng. 22, 173

Xu B., Bansal P.K. (2002) Appl. Therm. Eng. 22, 1801

Yilmaz T., Ünal S. (1996) ASME J. Fluids Eng. 118, 150

Zhang C., Ding G. (2004) Int. J. Refrig. 27, 17

Melo C., Ferreira R.T.S., Boabaid Neto C., Concalves J.M. (1999) Appl. Therm. Eng. 19, 669

M.O. McLinden, S.A. Klein, E.W. Lemmon, A.P. Peskin, REFPROP Version 6.0 (National Institute of Standards and Technology, Gaithersburg, Maryland, 2000)

Vacek V., Hallewell G., Lindsay S. (2001) Fluid Phase Equilib. 185, 305

Vacek V., Hallewell G., Ilie S., Lindsay S. (2000) Fluid Phase Equilib. 174, 191

S.D. Chang, S.T. Ro, in 1996 International Refrigeration Conference, vol. 83 (Purdue Univ., Lafayette, Indiana, 1996)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vacek, V., Vinš, V. A Study of the Flow through Capillary Tubes Tuned for a Cooling Circuit with Saturated Fluorocarbon Refrigerants. Int J Thermophys 28, 1490–1508 (2007). https://doi.org/10.1007/s10765-007-0294-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-007-0294-8