Abstract

Effective alternatives to synthetic fiber composites have been found in natural fiber composites, which are being increasingly used in a wide range of practical applications. This study focuses on the development and evaluation of a hybrid composite, which involves blending natural and synthetic fibers using a hand lay-up process. Using statistical variance analysis, the study seeks to leverage the unique characteristics of each fiber composite. This article explores the effects of different fiber orientations, sequencing, and the addition of nanoparticles on important mechanical properties, particularly flexural strength. Through the utilization of the response surface approach, mathematical models are developed to analyze these mechanical properties. Through statistical analysis, it has been found that the orientation and sequencing of fibers have a considerable impact on mechanical parameters. Additionally, the type of nanoparticles chosen also plays a role in determining the strength of the composite material. In particular, fibers aligned at a 90-degree angle demonstrate improved mechanical properties, especially when combined with a 5% concentration of nanoparticles. The latest iteration of the composite material shows significant performance improvement. Specifically, when the fibers are oriented at a 90-degree angle, using sequence 1, and with a nanoparticle content of 5%, the flexural strength is enhanced by an impressive 50%.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

Code availability

Not applicable.

References

Balachandran, G.B., Alexander, A.B., Murugesan, P., David, P.W., Shanmugasundaram, K.K., Sankarraj, K., Ramachandran, T., Ramachandran, M.E., Kasi, P.: Harnessing the Potential of Bellamya Eburnea Shell-Derived Nanoparticles through Electro-mechanical Optimization in the Performance of PCL Bio-composites: A Green Insulation Revolution, pp. 1–15. Waste and Biomass Valorization (2023)

Singh, S.P., Dutt, A., Hirwani, C.K., Chitrakar, S.: Mechanical and thermal behaviour of rice bran green composite using RSM and design of experiment techniques. Advances in Materials Science and Engineering, 2023. (2023)

Sakin, R.: Layup design optimization for e-glass woven roving fabric reinforced polyester composite laminates produced by VARTM. Fibers Polym. 22(2), 509–527 (2021)

Bakkiyaraj, M.: Finding the optimum concentration of silicon carbide and graphite particles on the tensile strength, hardness and wear properties of aluminium matrix composites by RSM approach. Surf. Topogr. Metrol. Prop. 9(2), 025018 (2021)

Van, M.N., Nguyen, V.A.: Optimization of the Engineering Properties of Cement Concrete Containing Gravel and Waste Rock using dense packing and response surface methodology. Periodica Polytech. Civil Eng. 67(4), 1246–1263 (2023)

Zhou, Z., Wang, J., Tan, K., Chen, Y.: Enhancing Biochar Impact on the Mechanical properties of Cement-based Mortar: An optimization study using response surface methodology for particle size and content. Sustainability. 15(20), 14787 (2023)

Esonye, C., Onukwuli, O.D., Anadebe, V.C., Ezeugo, J.N.O., Ogbodo, N.J.: Application of soft-computing techniques for statistical modeling and optimization of Dyacrodes Edulis seed oil extraction using polar and non-polar solvents. Heliyon, 7(3). (2021)

Zhang, C., Lu, F., Wu, J., Zhang, K., Lin, B., Qin, F.: November. Research on three-point bending performance of hollow-core rod pyramidal gradient lattice sandwich beam. In: Structures, vol. 57, p. 105165. Elsevier (2023)

Chau, N.L., Dao, T.P., Nguyen, V.T.T.: An efficient hybrid approach of finite element method, artificial neural network-based multiobjective genetic algorithm for computational optimization of a linear compliant mechanism of nanoindentation tester. Mathematical Problems in Engineering, 2018. (2018)

Jiang, R., Sun, X., Liu, H., Liu, Y., Mao, W.: Microstructure and mechanical properties improvement of the Nextel™ 610 fiber reinforced alumina composite. J. Eur. Ceram. Soc. 41(10), 5394–5399 (2021)

Shahraki, M., Sohrabi, M.R., Azizian, G., Narmashiri, K.: Reliability Assessment of CFRP-Strengthened Deficient Steel SHS columns. AUT J. Civil Eng. 3(1), 23–36 (2019)

Bellairu, P.K., Bhat, S., Gijo, E.V., Mangalore, P.: Multi-response modelling and optimization of agave cantala natural fiber and multi-wall carbon nano tube reinforced polymer nanocomposite: Application of mixture design. Fibers Polym. 23(4), 1089–1099 (2022)

Sojobi, A.O., Liew, K.M.: Multi-objective optimization of high performance bio-inspired prefabricated composites for sustainable and resilient construction. Compos. Struct. 279, 114732 (2022)

Kayaaslan, M., Coskun, T., Unlu, U.M., Sahin, O.S.: Effects of thickness, fibre orientation and fabric textile on the low-velocity impact performances of thermoset and thermoplastic composites. J. Thermoplast. Compos. Mater. 36(11), 4408–4429 (2023)

Phiri, R., Rangappa, S.M., Siengchin, S., Marinkovic, D.: Agro-waste natural fiber sample preparation techniques for bio-composites development: Methodological insights. Facta Universitatis Series: Mech. Eng. 21(4), 631–656 (2023)

Acknowledgements

The author thanks the management of Saveetha School of Engineering, SIMATS, for giving their extended support to complete the work.

Author information

Authors and Affiliations

Contributions

S.J.A. and R.S. contributed to the design and implementation of the research, to the analysis of the results and to the writing of the manuscript. T.S. and A.P. wrote the paper with input from all authors.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

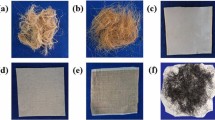

Arunachalam, S.J., Saravanan, R., Sathish, T. et al. Effect of nano-particle weight percent on the flexural strength of Jute/kenaf/glass fiber composite using RSM. Hyperfine Interact 245, 83 (2024). https://doi.org/10.1007/s10751-024-01920-2

Accepted:

Published:

DOI: https://doi.org/10.1007/s10751-024-01920-2