Abstract

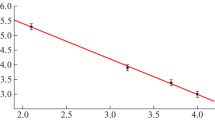

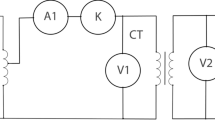

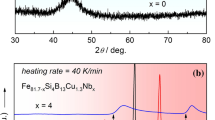

Amorphous Fe78Si9B13 alloy ribbons were heat treated between 296 and 763 K, using heating rates between 1 and 4.5 K/min. Whereas one ribbon partially crystallized at T x = 722 K, the other one partially crystallized at T x = 763 K. The partially crystallized ribbon at 722 K, heat treated using a triangular form for the heating and cooling rates, was substantially less fragile than the partially crystallized at 763 K where a tooth saw form for the heating and cooling rates was used. Vickers microhardness and hyperfine magnetic field values behaved almost concomitantly between 296 and 673 K. The Mössbauer spectral line widths of the heat-treated ribbons decreased continuously from 296 to 500 K, suggesting stress relief in this temperature range where the Vickers microhardness did not increase. At 523 K the line width decreased further but the microhardness increased substantially. After 523 K the line width behave in an oscillating form as well as the microhardness, indicating other structural changes in addition to the stress relief. Finally, positron lifetime data showed that both inner part and surface of Fe78Si9B13 alloy ribbons were affected distinctly. Variations on the surface may be the cause of some of the high Vickers microhardness values measured in the amorphous state.

Similar content being viewed by others

References

Devaud-Rzepski J., Quivy A., Harmelin M., Chevalier J.-P. and Calvayrac Y., Electron Microscopy of the initial states of crystalyzation in ferrous glassy alloys: observation of a mode inversion, In: Baró M. D. and Clavaguera N. (eds.), Current Topics on Non-Crystalline Solids, Proceedings of the First International Workshop on Non-Crystalline Solids, World Scientific, 1986, pp. 231–236.

Zauska A. and Matyja H., Crystallization characteristics of amorphous Fe-Si-B alloys, J. Mater. Sci. 18 (1983), 2163–2172.

Ramanan V. R. V. and Fish G. E., Crystallization kinetics in Fe-B-Si metallic glasses, J. Appl. Phys. 53(3) (1982), 2273–2275.

Rawers J. C., McCune R. A. and Adams A., Crystallization of amorphous Fe78B13Si9, J. Mater. Sci. Lett. 7 (1988), 958–960.

Lu K. and Wang J. T., Activation energies for crystal nucleation and growth in amorphous alloys, Mater. Sci. Eng. A133 (1991), 500–503.

Linderoth S., González J. M., Hidalgo C., Liniers M. and Vicent J. L., Correlation between positron lifetime results and magnetic behaviour upon relaxation and crystallization of an iron-based amorphous alloy, Solid State Commun. 65(12) (1988), 1457–1460.

Bang J. Y. and Lee R. Y., Crystallization of the metallic glass Fe78B13Si9, J. Mater. Sci. 26 (1991), 4961–4965.

Li J.-M., Quan M.-X. and Hu Z.-Q., Spectra investigation on hall-petch relationship in nanocrystalline Fe78Si9B13 alloy, Appl. Phys. Lett. 69(11) (1996), 1559–1561.

Chokhsi A. H., Rosen A., Karch J. and Gleiter H., Scr. Metall. 23 (1989), 1679.

Gleiter H., Prog. Mater. Sci. 33 (1989), 223.

Weertman J. R., Some unresolved issues concerning mechanical behavior of nanocrystalline metals, Mat. Sci. Forum 386–388 (2002), 519–520.

Sun X., Cabral-Prieto A. and Jose Yacaman M., Sun W., Investigations on in situ nanocrystallization and magnetic properties for amorphous Fe78Si9B13 ribbons, Mater. Res. Soc. Symp. Proc. 562 (1999), 301–306.

Yavari A. R., Barrue R., Harmelin M. and Perron J. C., Magn. Magn. Mater., 69 (1987), 43.

Huang D.-R. and Li J. C. M., High frequency magnetic properties of an amorphous Fe78Si9B13 ribbon improved by a. c. Joule heating, Mater. Sci. Eng. A133 (1991), 209–212.

Blum N. A., Moorjani K., Poehler T. O. and Satkiewicsz F. G., Mössbauer investigation of sputtered ferromagnetic amorphous Fe x B100 − x films, J. Appl. Phys. 53 (3) (1982), 2074–2076.; Chien C. L., Musser D., Gyogy E. M., Sherwood R. C., Chen H. S., Luborsky F. E. and Walter J. L., Phys. Rev., B 20 (1979), 283.

Vavassori P., Ronconi F. and Puppin E., Surface crystallization and magnetic properties of amorphous Fe80B20 alloy, J. Appl. Phys. 82(12) (1997), 6177–6180.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cabral-Prieto, A., Garcia-Santibañez, F., López, A. et al. Vickers Microhardness and Hyperfine Magnetic Field Variations of Heat Treated Amorphous Fe78Si9B13 Alloy Ribbons. Hyperfine Interact 161, 69–81 (2005). https://doi.org/10.1007/s10751-005-9169-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10751-005-9169-1