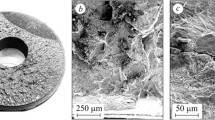

An experimental study of the structure and properties of metal in areas of cracks in turbine body components made of steel grade 15Kh1M1FL is conducted that shows a drop in ultimate strength with an increase in running time to the level of operating stresses. It is established that the appearance of deep cracks is accompanied by the presence of primary and selective recrystallization, in which structural strengthening created by factory heat treatment gradually disappears. Connected with this metal stress-rupture strength at 540°C for 105 h decreases by 10 – 15 MPa. Unfavorable associated signs are complete carbide phase spheroidization, an especially low critical brittleness temperature lower by 50°C, a low value of critical crack opening at the operating temperature, i.e., less than 0.25 mm, hot hardness of less than 850 MPa, and presence of micro-damage of more than 3 points on the scale for low-alloy steels.

Similar content being viewed by others

References

V. F. Rezinskikh, V. I Gladshtein, and G. D. Avrutskii, Increase in the Life of Long-Term Operating Turbines [in Russian], Izd. dom MÉI, Moscow (2007)

V. I Gladshtein, A. A. Lyubimov, and O. A. Pul’cheva, “Evaluation of the reliability of steam turbine cast body components having repeated repair welds,” Élektr. Stantsii, No. 8, 24 – 28 (2007).

N. V. Bugai, T. G. Berezina, and I. I. Trunin, Operating capacity and Endurance of Power generation Equipment Metal [in Russian], Énergoatomizdat, Moscow (1994).

S. S. Gorelik, Metal and Alloy Recrystallization [in Russian], Metallurgiya, Moscow 91967).

A. B. Popov, S. G. Khanzhin, V. I. Gladshtein, A. I. Troitskii, and A. V. Surkov, “Reasons for stop vale metal of K-300-240 turbines operating for about 300 thousand hours,” Énergetik, No. 11, 13 – 20 (2016).

V. I. Gladshtein, Microdamage of High-Temperature Energy Equipment Component Metal [in Russian], Mashinostroenie, Moscow (2014).

V. I. Gladshtein and A. I. Troitskii, Change in service properties of steam turbine metal with running time more than 330 thousand hours,” Teploénergetika, No. 1, 84 – 92 (2017).

V. I. Gladshtein, A. I. Troitskii, and a. A. Lyubimov, “Evaluation of the long-term operating life of cast components of chromiummolybdenum-vanadium steel with respect to microdamage,” Élektr. Stantsii, No. 4, 50 – 55 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Élektricheskie Stantsii, No. 8, August 2022, pp. 24 – 32. DOI: https://doi.org/10.34831/EP.2022.1093.8.004

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gladshtein, V.I., Lyubimov, A.A. Structural Signs of Exhaustion of Metal Resource in Crack Zones of Steam Steel 15KH1M1FL Turbine Body Components. Power Technol Eng 56, 731–738 (2023). https://doi.org/10.1007/s10749-023-01582-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10749-023-01582-0