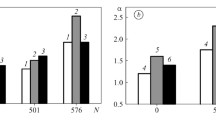

Notched sample modeling was used to demonstrate effect of technology used for manufacturing pipes from steel 10Kh9MFB-Sh (piercing-broaching or electroslag remelting) on metal fracture toughness under creep conditions of 600°C at subcritical and avalanche stages of destruction. According to the subcritical crack growth and metal fracture toughness resistance determined on the samples, the lifespan of pipes having initial defects was evaluated. Calculations were carried out for pipes of two types including a hot reheat (HRH) steam line operating under a pressure of 4.1 MPa and a main steam (MS) line operating under a pressure of 14.0 MPa. Taking into account the obtained characteristics of fracture toughness, the use of electroslag remelting technology was shown to provide a durability of about 3 times that of piercing-broaching approaches. Differences in the pressure level and wall thickness shown to result in a tenfold increase in the durability of the HRH and MS steam pipelines at 600°C justify a different cracking risk classification, which should be taken into account in conducting operational monitoring.

Similar content being viewed by others

References

V. N. Skorobogatykh, L. Ya. Levkov, I. A. Shchenkova, K. N. Utkina, P. A. Kozlov, D. A. Prudnikov, A.M. Bazhenov, D. A. Shurygin, D. K. Terekhin, and T. V. Perevezentseva, “Technology and complex of properties of electroslag remelting billets for equipment of TPP and NPP,” Tyazh. Mashinostr., No. 11 – 12, 31 – 37 (2014).

V. I. Gladshtein and A. A. Lyubimov, “Determination of the resource of steam turbine rotor elements under creep conditions by modeling,” Zavod. Lab. Diagn. Mater., 85(9), 52 – 60 (2019).

V. I. Gladshtein and A. I. Troitskii, “Forecast of the survival time for the rapid assessment of the resource characteristics of the metal parts of steam pipelines made of 10Kh9MFB-Sh steel,” Élektr. Stantsii, No. 1, 8 – 15 (2019).

Specifications TU 14-3R-55-2001. Seamless Steel Pipes for Steam Boilers and Pipelines [in Russian].

State Standard GOST 25.506–85. Calculations and Strength Tests. Methods for Mechanical Testing of Metals. Determination of Fracture Toughness Characteristics under Static Loading [in Russian], Standardinform, Moscow (2005).

V. I. Gladstein and A. I. Troitskii, “Methods for assessing fracture toughness when testing the long-term strength of metal of high-temperature parts in steam turbines,” Zavod. Lab. Diagn. Mater., 79(9), 56 – 60 (2013).

V. I. Gladstein, “Express assessment of metal characteristics of high-temperature parts of turbines and steam lines made of high-chromium steels,” Élektr. Stantsii, No. 5, 27 – 33 (2010).

Yu. Murakami (ed.), Handbook on Stress Intensity Factors [Russian translation], Mir, Moscow (1990).

Y. Tsyda, M. Miyazaki, and A. Kalpan, “Advanced 12% Cr steel for high-temperature Rotors, EPRI program (RP1403) improved coal-fired power plants turbine research and development,” in: 3th Int. Conf. on Improved Coal-Fired Power Plants (1991).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Élektricheskie Stantsii, No. 6, June 2020, pp. 41 – 46.

Rights and permissions

About this article

Cite this article

Gladshtein, V.I., Kolesova, A.P. Investigation into the Effect of Manufacturing Technology on the Fracture Toughness and Durability of Steam Pipes Made of 10Kh9MFB-Sh Steel. Power Technol Eng 54, 560–565 (2020). https://doi.org/10.1007/s10749-020-01251-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10749-020-01251-6